Meta Description:

Learn how pickling and passivation improve corrosion resistance in stainless steel tubes. Explore DLSS’s cleaning methods, ASTM standards, and industry-specific applications.

Introduction

Even the highest-grade stainless steel can suffer from surface contamination during tube forming, welding, or heat treatment. To restore the full corrosion resistance of stainless steel tubes, manufacturers must apply pickling and passivation processes—two chemical surface treatments essential to durability and cleanliness.

At DLSS, we apply both treatments as part of our tube finishing process, in accordance with international standards like ASTM A967 and EN ISO 16048, ensuring a clean, passive surface ideal for demanding environments like heat exchangers, food processing, and oil & gas pipelines.

1. What Is Pickling?

Pickling is a chemical treatment used to remove oxide scale, welding discoloration, and embedded iron particles from stainless steel surfaces.

- DLSS uses nitric acid + hydrofluoric acid or citric-based formulations for safer, eco-friendly pickling.

- Common targets:

- Heat tint (from annealing or welding)

- Black oxide (from hot rolling or forming)

- Embedded carbon steel particles

Reference: ASTM A380 – Standard Practice for Cleaning, Descaling, and Passivation

Keywords: pickling stainless tube, oxide removal, nitric acid HF cleaning

2. What Is Passivation?

Passivation is the process of applying a mild oxidizing acid (typically nitric or citric acid) to:

- Remove free iron from the surface

- Allow formation of a stable chromium-rich oxide layer

- Enhance corrosion resistance in chloride and acidic environments

Passivation does not remove scale or heavy discoloration—hence, it is always performed after pickling, not as a substitute.

Learn more: ASTM A967 – Passivation of Stainless Steel

Keywords: passivated stainless pipe, ASTM A967 standard, free iron removal

3. Why These Treatments Are Crucial

| Step | Effect | Benefit |

|---|---|---|

| Pickling | Removes scale and contaminants | Prevents localized corrosion and rust |

| Passivation | Forms chromium oxide protective film | Restores natural corrosion resistance |

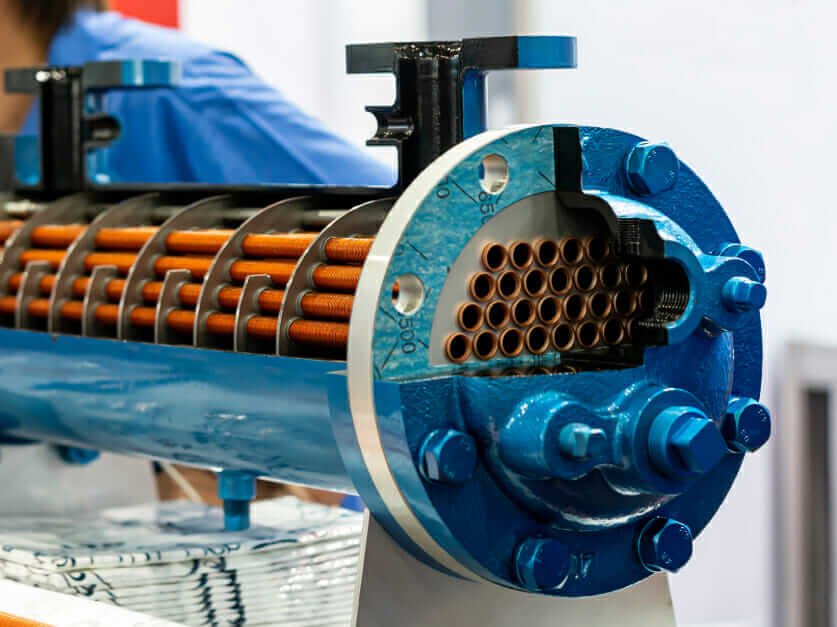

Industries that demand passivated stainless steel:

- Pharmaceutical and biotech tubing

- Heat exchanger systems (especially for seawater)

- Food-grade piping (dairy, brewing, beverage)

- Nuclear and power plant condensers

4. DLSS Pickling & Passivation Workflow

- Visual inspection of tube surface (before pickling)

- Immersion or spray pickling using safe, neutralized acid blends

- Thorough rinsing with deionized water

- Passivation stage with nitric acid or citric acid (per ASTM A967 methods 1–7)

- Drying and final inspection, including surface roughness, gloss, and color

- Optional: Ferrite test or free iron test (per ASTM A380 water-wetting test)

DLSS can also provide pickled tubes in coil form, U-bend, or cut-to-length with clean ID/OD finish.

5. Surface Condition Options

DLSS offers multiple surface conditions:

| Finish Type | Description | Application |

|---|---|---|

| Pickled (P) | Matte silver, chemically descaled | Boilers, pipelines |

| Bright Annealed (BA) | Mirror-like, oxide-free | Instrumentation, clean rooms |

| Passivated | Clean, stable passive layer (invisible) | Food, pharma, nuclear |

| Polished (Grinded) | Controlled surface roughness (e.g., Ra ≤ 0.8 μm) | Sanitary and dairy tubing |

Optional: ISO 15730 – Immersion and spray pickling of stainless steel

6. Real-World Case Study

Client: European pharmaceutical equipment integrator

Tube Spec: ASTM A269 TP316L, OD 25.4 mm x 1.65 mm, 6m

Requirement: Pickled + passivated finish, Ra ≤ 0.8 μm, EN 10204 3.1

Solution:

- DLSS applied pickling & passivation per ASTM A967, method 1 (Nitric 2)

- Surface roughness measured using Mitutoyo profilometer

- Delivered full documentation + third-party SGS witness report

Outcome: Customer passed FAT and added DLSS to preferred vendor list.

Conclusion

Pickling and passivation are not cosmetic treatments—they are functional, science-backed processes that restore and enhance the corrosion resistance of stainless steel tubes. By adhering to international standards and customizing the process by alloy, DLSS ensures our customers receive tubing that performs from the inside out.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Have a specification that requires pickling, passivation, or documentation per ASTM A967 or EN standards? Contact DLSS to discuss technical requirements and receive test-certified stainless steel tubes.