Meta Description:

Discover what bright annealed stainless steel tubes are, how they’re produced, and why they are essential in hygienic and high-purity applications such as pharmaceuticals, food processing, and semiconductors.

Introduction

In industries where surface finish, corrosion resistance, and cleanliness are critical, Bright Annealed (BA) stainless steel tubes are the preferred solution. With a mirror-like internal and external finish, these tubes not only look premium—they perform better in corrosive and high-purity environments.

At DLSS, we manufacture and export high-precision BA tubes that meet international standards and the strict demands of cleanroom-grade industries.

1. What Is Bright Annealing?

Bright Annealing is a heat treatment process performed in a controlled, inert atmosphere (usually hydrogen or nitrogen mix) to prevent oxidation and preserve surface brightness.

Key Differences from Normal Annealing:

| Normal Annealing | Bright Annealing |

|---|---|

| Performed in air | Performed in inert gas atmosphere |

| Results in scale or discoloration | Produces bright, smooth finish |

| Requires acid pickling | No pickling or passivation needed |

2. Characteristics of Bright Annealed Tubes

- Mirror-Like Surface Finish (Ra ≤ 0.2 µm)

- Excellent Corrosion Resistance

- Low Surface Contamination (No Pickling Residue)

- High Dimensional Accuracy

- Improved Flow Efficiency in Fluid Systems

BA tubes are widely used in systems requiring ultra-smooth surfaces to avoid fluid entrapment, biofilm formation, or metal ion leaching.

3. Manufacturing Process at DLSS

- Cold Drawing of Stainless Steel Hollow

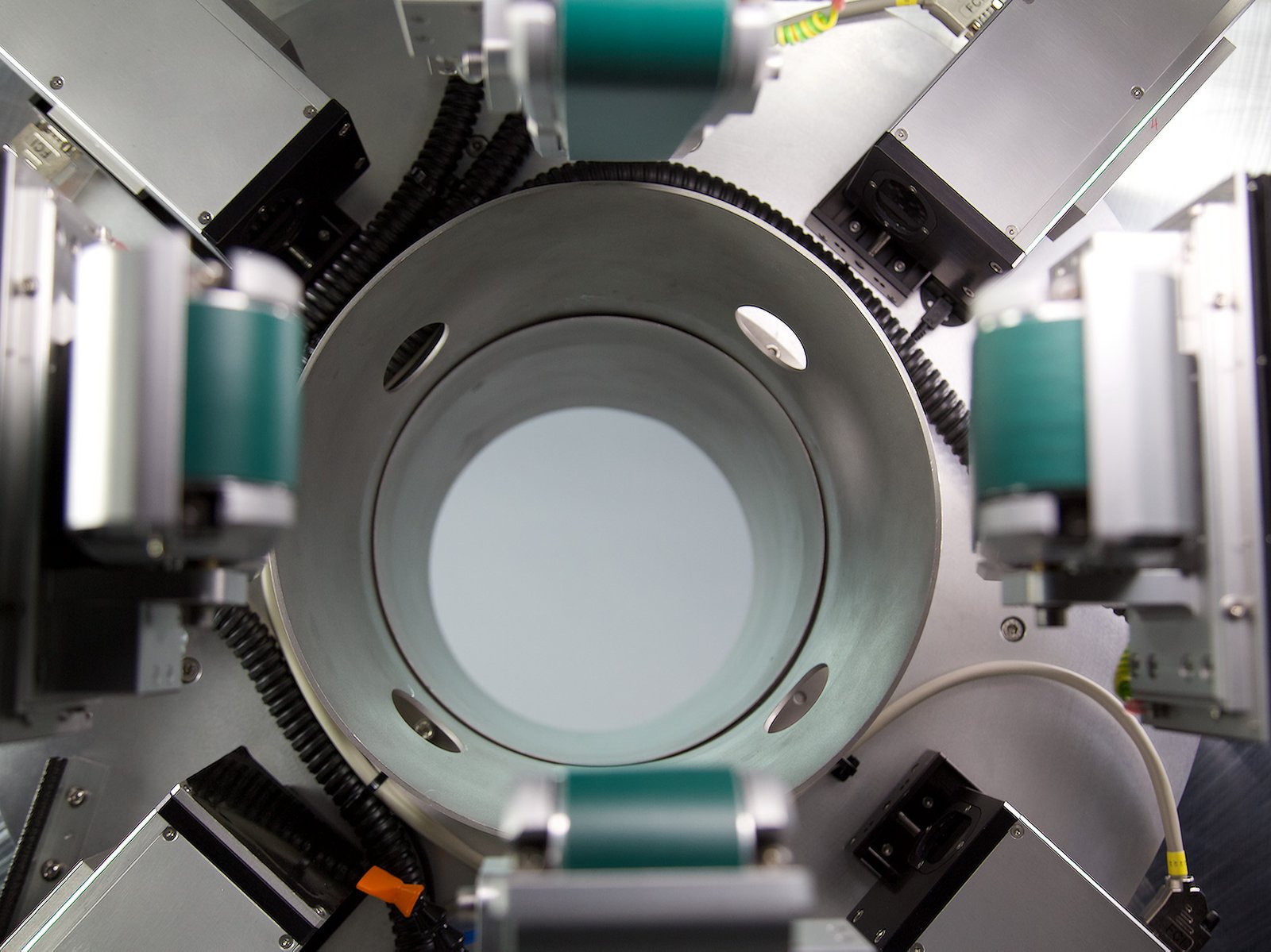

- Solution Annealing in Inert Atmosphere Furnace (Hydrogen Purge)

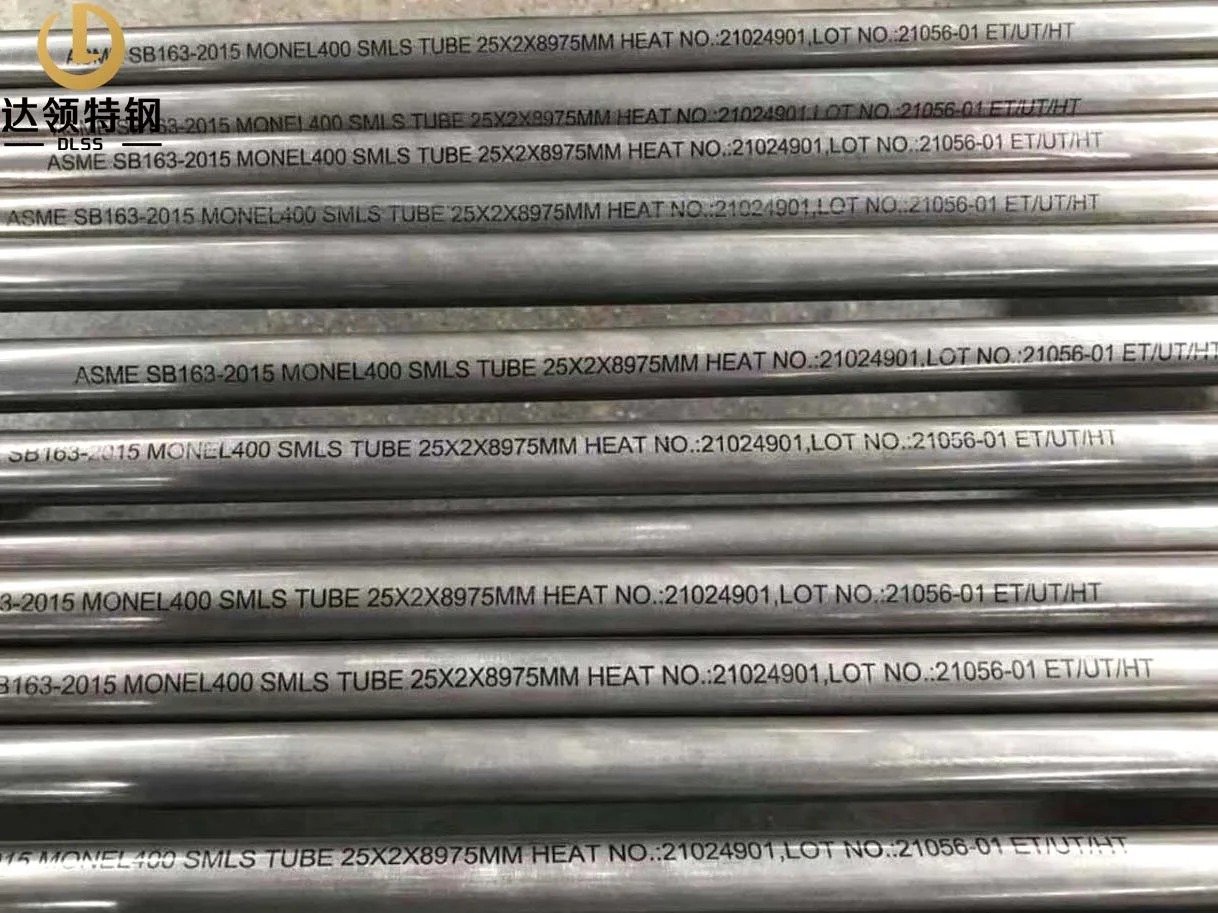

- Automatic Straightening and Non-Destructive Testing (ET/UT)

- Mirror Surface Polishing (Optional: ID/OD)

- Hydrostatic Testing and Final Inspection

- Cleanroom Packing in PE Bags + End Caps + Hard Cases

All products are supplied with EN 10204 3.1 or 3.2 certification upon request.

4. Available Specifications

| Grade | Size Range (OD × WT) | Standard | Surface Finish |

|---|---|---|---|

| TP304 / 304L | 6mm – 50.8mm × 0.5–2.5mm | ASTM A269 / A213 | Bright Annealed |

| TP316 / 316L | 6mm – 38.1mm × 0.7–2.0mm | ASTM A269 / EN 10216-5 | BA / Polished |

| TP316L BA+EP | 6.35mm × 1.0mm typical | SEMI F20, DIN 11850 | BA + Electropolished |

| TP321 / 347 | Upon request | Custom orders | Bright Annealed |

Optional: Ultrasonic Test (per ASTM E213), Eddy Current, PMI, Grain Size

5. Applications of Bright Annealed Tubes

| Industry | Application |

|---|---|

| Pharmaceuticals | WFI piping, autoclaves, sterile lines |

| Food & Beverage | Dairy lines, beer fermenters, sugar tanks |

| Semiconductors | Ultra-pure water delivery |

| Cosmetics | GMP-certified mixing pipelines |

| Medical Device Plants | Cleanroom-grade air and gas tubing |

Want to see real installations? Visit our project showcase page

6. Common Misconceptions

“Pickled tubes are just as clean.”

Pickling removes oxide scale, but leaves chemical residues. BA tubes come out clean, smooth, and chemically stable—ideal for contact with sensitive media.

“All BA tubes are the same.”

No. The purity of atmosphere, temperature control, and tube preparation all affect the final finish. DLSS uses high-precision furnaces and third-party validation to ensure quality.

FAQs

Q1: What is the Ra value of DLSS bright annealed tubes?

Ra ≤ 0.2 µm (inside surface), suitable for hygienic and semi-clean applications. For electropolished tubes, Ra can reach ≤ 0.05 µm.

Q2: Can BA tubes be bent or coiled?

Yes. We offer U-bend and coil configurations for BA tubes upon request, maintaining surface finish during forming.

Q3: What’s the difference between BA and EP tubes?

EP (Electropolished) tubes are usually made from BA tubes with further internal surface polishing using electrolytic methods. EP is ideal for ultra-pure or semiconductor-grade systems.

Q4: What packaging options are available?

All DLSS BA tubes are sealed with PE caps, packed in PE film, and stored in clean hard cases or wooden crates, suitable for export and cleanroom entry.

Conclusion

Bright Annealed stainless steel tubes offer a cleaner, smoother, and more corrosion-resistant option for industries where hygiene and purity are not negotiable. DLSS delivers tubing with traceable quality, tested performance, and global support.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Looking for high-purity stainless steel tubing? DLSS provides BA and BA+EP tubes tailored to your project’s demands—with fast delivery and compliance documentation.