Meta Description:

EN 10204 3.2 certification is often mandatory for high-spec tubing projects. Learn what it means, how to prepare, and how to ensure your stainless steel heat exchanger tubes pass 3.2 inspection.

Introduction

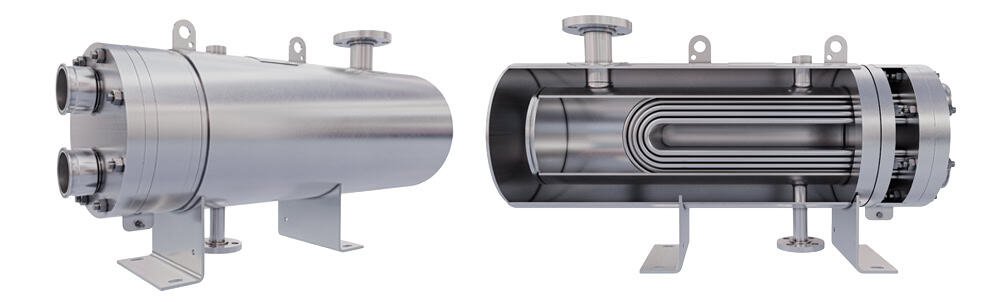

For heat exchanger projects in industries like oil & gas, power generation, and refineries, third-party certification is often non-negotiable.

One of the highest levels of documentation is the EN 10204 3.2 certificate, which proves that material, testing, and inspection are approved by an independent authority—often required by EPC clients or government contracts.

This guide explains what 3.2 certification is, how it differs from 3.1, and what you need to pass it smoothly—without delays or rejections.

What Is EN 10204 3.2 Certification?

Under the EN 10204 standard, 3.2 certification confirms that:

- The manufacturer’s quality control has tested and approved the material

- An independent third party (like TÜV, DNV, BV, Lloyd’s) or the buyer’s appointed inspector has verified compliance

- The certificate includes all mechanical, chemical, and dimensional test results, witnessed or reverified by the inspector

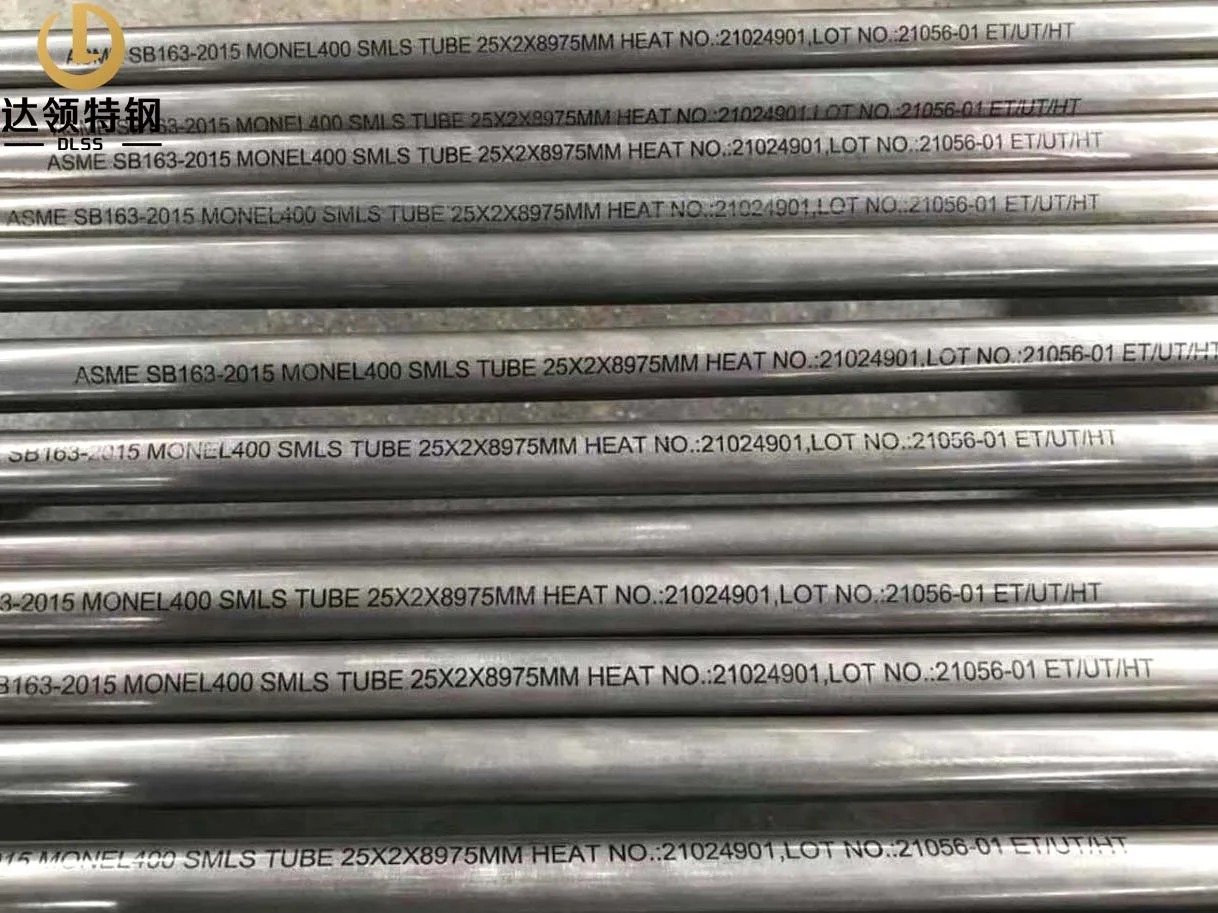

For heat exchanger tubing, this applies to seamless stainless steel tubes, often under ASTM A213, A312, or EN 10216-5.

Official standard: EN 10204 explained by BSI

3.1 vs. 3.2: What’s the Difference?

| Feature | EN 10204 3.1 | EN 10204 3.2 |

|---|---|---|

| Issued by | Manufacturer’s QA dept | Manufacturer + Independent Inspector |

| Third-party witness | Not required | Required |

| Data verified | By manufacturer only | By inspector or client representative |

| Typical use | General industrial supply | High-risk, critical, or regulated projects |

When Is 3.2 Certification Required?

- Government or regulated projects (e.g., nuclear, power plant, refinery projects)

- High-pressure heat exchanger systems

- Clients like Petrobras, Shell, YPF, TotalEnergies

- EPC contractors requiring full traceability and inspection witness

How to Prepare for a Successful 3.2 Inspection

1. Use a Qualified Manufacturer

Only manufacturers with a quality system (ISO 9001) and traceable material records can issue 3.2 documents with third-party validation.

2. Confirm Standards in Advance

Ensure your product meets:

- ASTM A213 or A312

- EN 10216-5 or EN 13480

- NACE MR0175 or ASME B31.3 where required

3. Plan the Witness Schedule

Coordinate with inspection agencies like SGS, BV, TÜV, DNV for:

- Heat number verification

- Dimensional checks

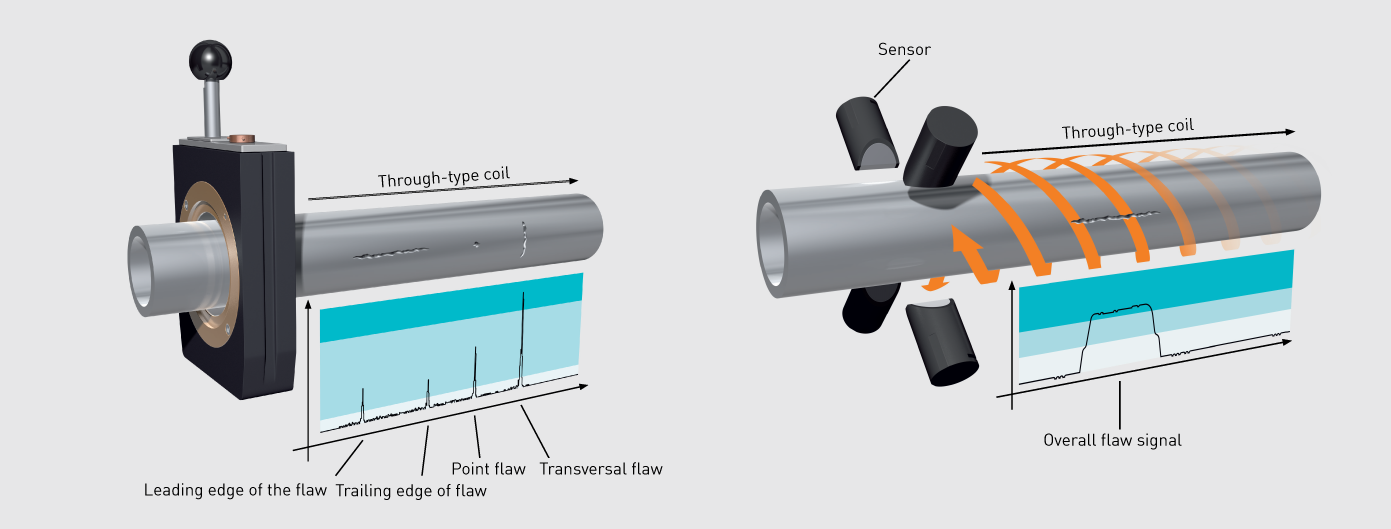

- Mechanical & chemical testing

- Final document signoff

4. Provide Full Documentation

Before certification, have ready:

- MTC (3.1 base report)

- Heat treatment records

- PMI / EC / UT / hydrostatic test reports

- Dimensional reports

- WPS/PQR (if welding applies)

Common Reasons for 3.2 Rejection

- Heat numbers on certificate don’t match product markings

- Surface defects or weld quality issues not meeting spec

- Missing or incomplete test documentation

- Failure to notify inspector before key production stages

DLSS Experience with 3.2 Certification

DLSS has passed 3.2 certifications for projects in:

- Brazil (FPSO and LNG) – TP316L and Incoloy 825 tubes

- Argentina – TP347H seamless tubes for hydrogen reformers

- Peru and Chile – Duplex exchanger tubes with SGS witness

- We coordinate inspection schedules, provide bilingual docs, and allow video inspection upon request

Frequently Asked Questions (FAQ)

Q1: Is a 3.2 certificate always required?

No. Many projects accept 3.1 unless pressure, safety, or legal compliance is critical.

Q2: Who can issue a 3.2 certificate?

It must be signed by both the manufacturer’s QA representative and an independent inspector (SGS, BV, TÜV, etc.)

Q3: What if the inspector is not available during production?

Remote or video inspection may be allowed. But approval must be agreed in advance by the client.

Q4: Can DLSS provide 3.2 tubes with short lead time?

Yes, for select grades and sizes in stock. For new production, we typically arrange inspection 2–3 days after test completion.

Conclusion

3.2 certification proves your stainless steel heat exchanger tubes are fully compliant, independently verified, and traceable—a key requirement for many international and government-backed projects.

DLSS supports the entire 3.2 process with technical documentation, certified test reports, and coordination with major inspection agencies—ensuring smooth approval and zero rework.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com