Introduction

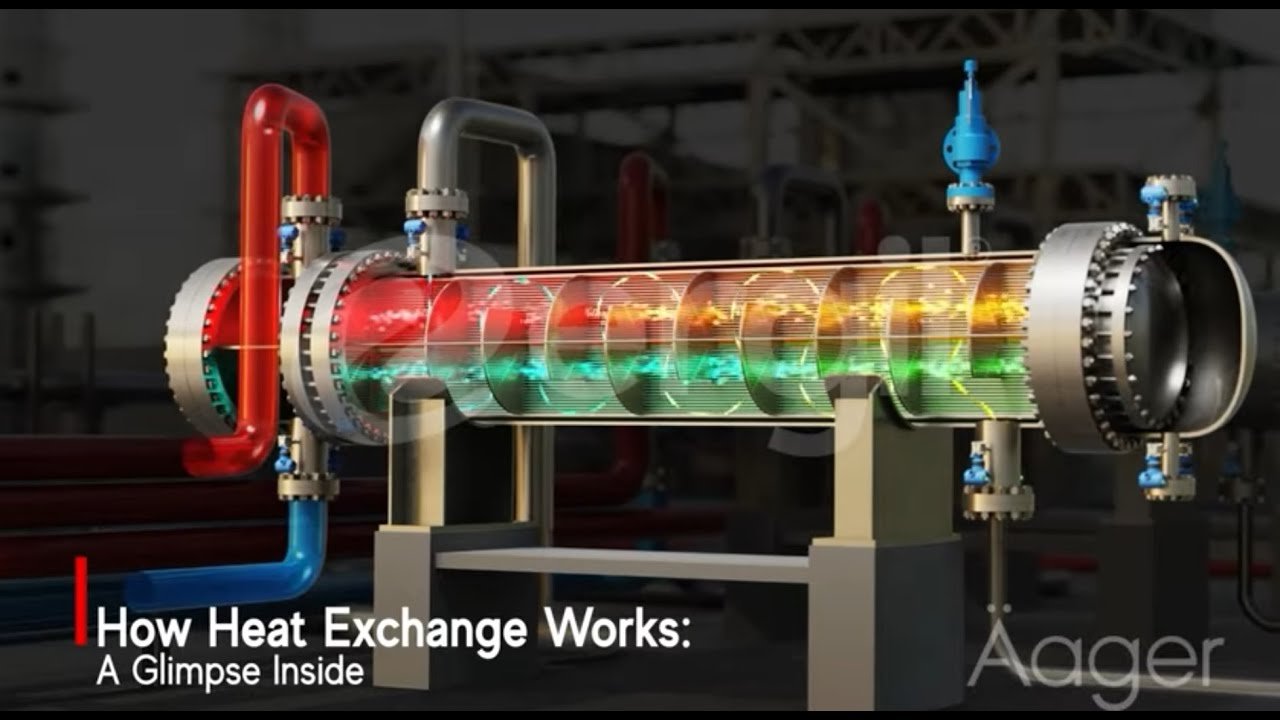

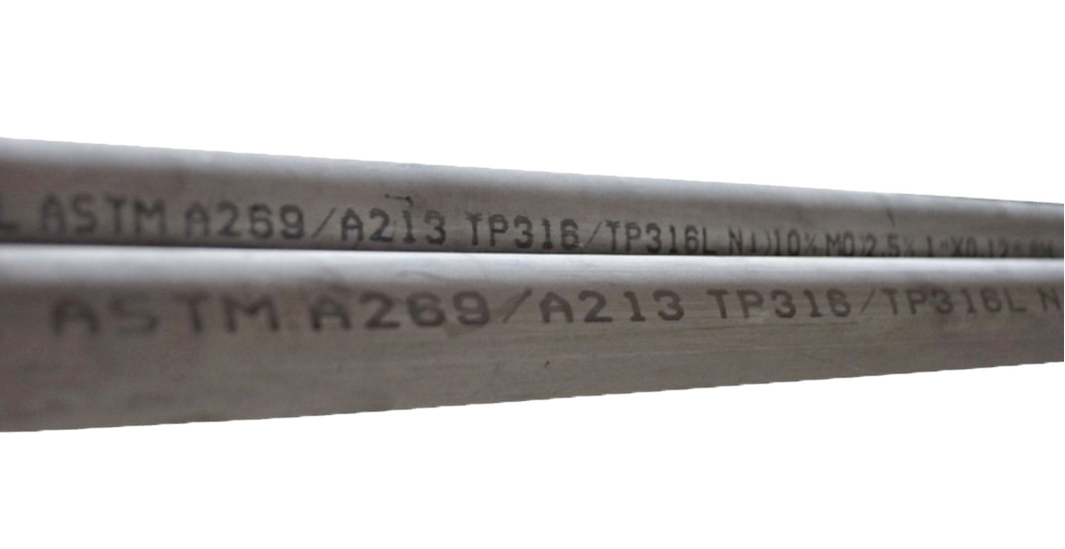

In high-temperature environments such as boilers, power plants, and petrochemical heat exchangers, alloy steel tubes are indispensable. One common choice is ASTM A199 T11, a Cr-Mo alloy steel that provides excellent creep resistance, mechanical strength, and durability. Recently, a customer requirement for T11 cold drawn tubes offers a valuable example of how this material meets the needs of demanding thermal applications.

Customer Requirement Example

The specific request included:

- Material: ASTM A199 T11 or equivalent

- Outside Diameter (OD): 15.875 mm

- Wall Thickness (WT): 2.11 mm

- Tube Length: 15,000 mm

- Quantity: 2,225 pieces

This specification reflects the rising demand for long-length, precision alloy steel tubes in heat exchanger and boiler applications.

Why Choose ASTM A199 T11?

T11 alloy steel belongs to the ferritic family of Cr-Mo steels, known for their excellent high-temperature performance:

- High-Temperature Strength: Resists creep and maintains integrity at elevated operating conditions.

- Oxidation Resistance: With 1.0–1.5% Cr and 0.44–0.65% Mo, T11 offers good oxidation resistance in flue gas and steam environments.

- Weldability: T11 tubes can be welded effectively while maintaining stable mechanical properties.

- Cost Efficiency: Compared to higher-alloy steels, T11 provides a reliable balance between performance and cost.

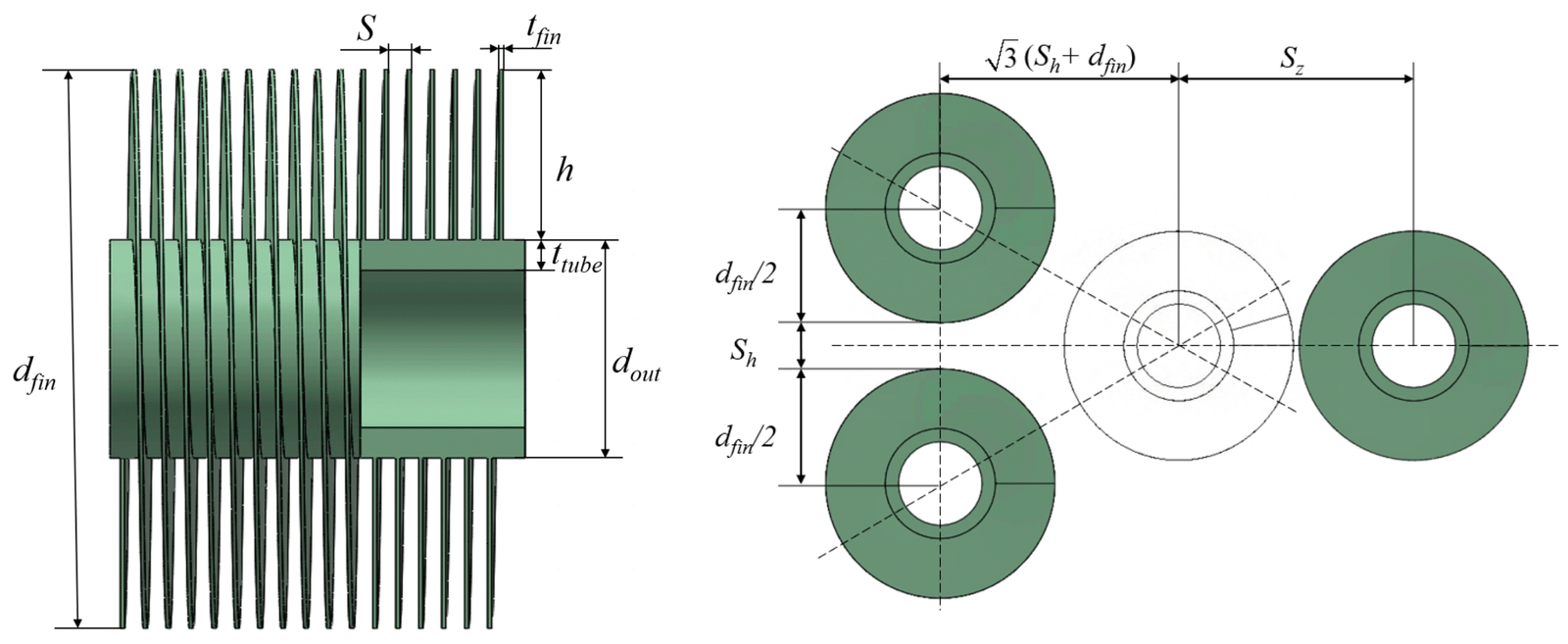

Technical Challenges of Cold Drawn Alloy Steel Tubes

Producing precision cold drawn tubes at 15 meters in length involves several challenges:

- Dimensional Accuracy: Maintaining OD and WT tolerances within ±0.05 mm across long lengths.

- Surface Quality: Smooth inner and outer surfaces to minimize scaling and fouling in service.

- Straightness: Critical for tube-to-tube sheet fit-up in heat exchanger assemblies.

- Heat Treatment: Proper normalizing and tempering cycles to ensure creep resistance and toughness.

DLSS Cold Drawing and Quality Solutions

DLSS ensures compliance with stringent requirements for alloy steel tubes:

- Cold Drawing Technology: Achieves precision tolerances and improved surface finish.

- Heat Treatment Expertise: Normalizing and tempering processes restore mechanical properties and refine grain structure.

- Testing & Certification:

- EN 10204 3.1 or 3.2 certificates

- 100% Eddy Current + Hydrostatic testing

- Mechanical and hardness testing for elevated temperature service

- Inspection Plans: Customized ITPs (Inspection & Test Plans) with third-party inspection options.

- Packaging: End caps, VCI protection, wooden cases for safe transport of long-length tubes.

Applications of Alloy Steel T11 Tubes

Alloy steel T11 tubes are widely used across industries:

- Boiler Tubes in thermal and power plants

- Superheaters & Reheaters in high-pressure steam systems

- Petrochemical Heat Exchangers handling elevated temperatures

- Economizers in power generation units

Their proven performance makes them a standard choice for operators seeking reliability and long service life.

Conclusion – Partnering with DLSS for Alloy Steel Tubes

This customer requirement for T11 cold drawn tubes illustrates the importance of precision and quality in high-temperature heat exchanger applications. DLSS provides engineered alloy steel tubes with strict dimensional control, certified testing, and international compliance.

For more details, contact info@dlsspipe.com or visit www.dlsspipeline.com. DLSS is your trusted partner for alloy steel heat exchanger tubes.