Meta Description:

Understand the key differences between ASTM A312 and ASTM A789 for stainless steel seamless tubes used in the oil & gas industry. Compare materials, applications, and testing requirements.

Introduction

In the oil and gas sector, selecting the right stainless steel tube standard is essential for long-term system performance. Among the most referenced specifications are:

- ASTM A312 – Seamless and welded austenitic stainless steel pipes

- ASTM A789 – Seamless and welded ferritic/austenitic (Duplex) stainless steel tubing

While both serve critical purposes in petroleum refining, offshore rigs, and midstream transport systems, they differ significantly in material composition, mechanical properties, and application scenarios.

This article provides a practical comparison to help you make informed decisions during specification, procurement, or design.

What Is ASTM A312?

ASTM A312 covers seamless and welded austenitic stainless steel pipes intended for:

- High-temperature service

- General corrosion resistance

- Common materials: TP304, TP316, TP321, TP347, TP904L

Typical Applications:

- Refinery piping for acids, steam, sulfur

- Process pipelines in LNG and gas processing

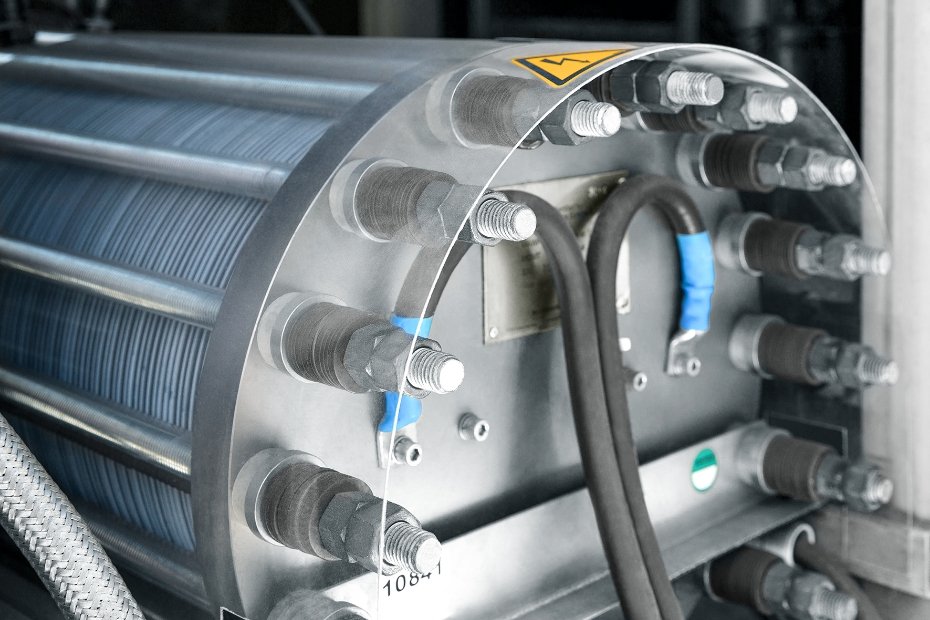

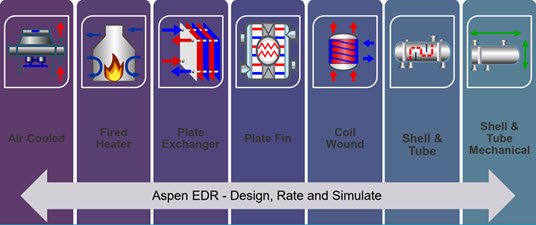

- U-bend tubes in heat exchangers, boilers

Key Features:

- High ductility and weldability

- Good resistance to oxidizing and moderately reducing environments

- Grades like TP316L are ideal for chloride-containing media

What Is ASTM A789?

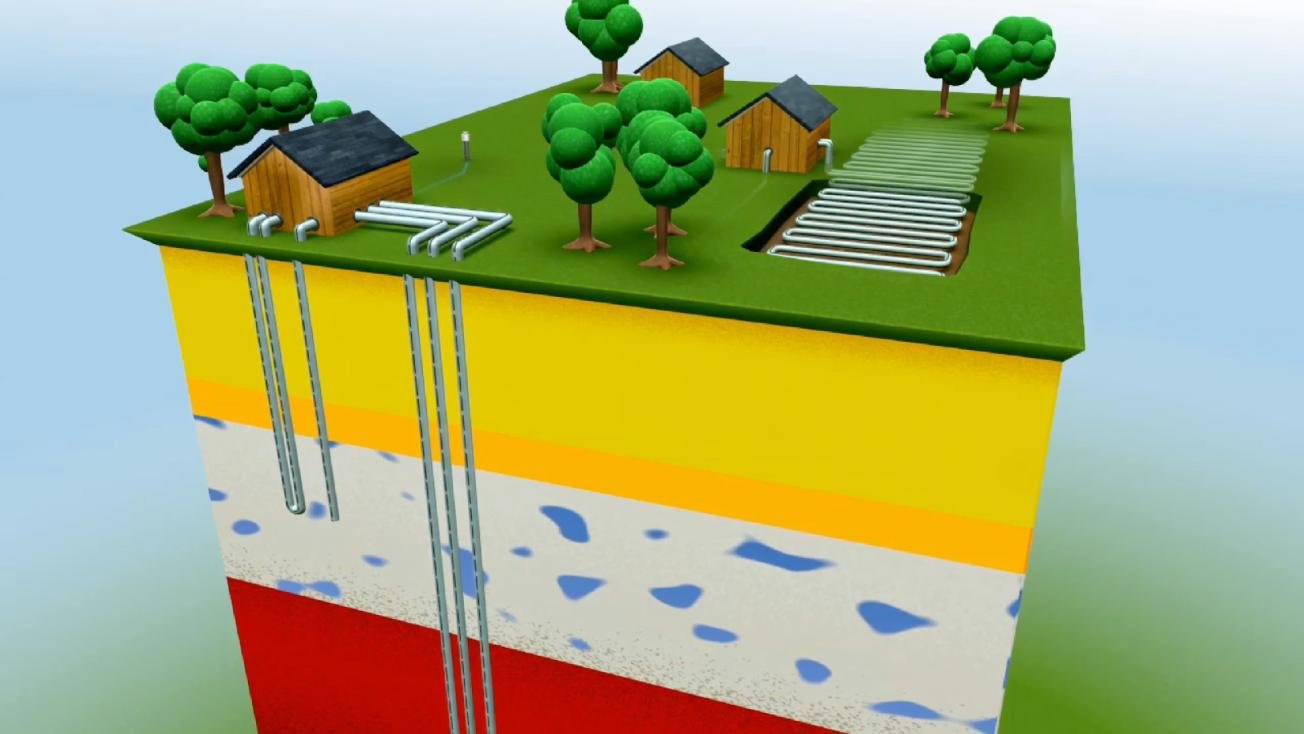

ASTM A789 covers seamless and welded Duplex stainless steel tubing, combining:

- Ferritic and austenitic microstructures

- Common materials: UNS S31803 (2205), S32205, S32750 (Super Duplex)

Typical Applications:

- Offshore oil platforms

- Subsea pipelines and manifolds

- Heat exchangers exposed to aggressive brine or sour service

Key Features:

- Superior strength (2x that of austenitic steels)

- High resistance to chloride pitting, crevice corrosion, and stress corrosion cracking

- Lower thermal expansion than austenitic grades

Technical Comparison Table

| Parameter | ASTM A312 | ASTM A789 |

|---|---|---|

| Material Type | Austenitic stainless steel | Duplex stainless steel |

| Typical Grades | TP304, TP316, TP321, TP904L | S31803, S32205, S32750 |

| Corrosion Resistance | Excellent (general & oxidizing) | Superior (chloride & sour) |

| Tensile Strength (min) | ~515 MPa (TP316L) | ~620 MPa (S32205) |

| Yield Strength (min) | ~205 MPa | ~450 MPa |

| Weldability | Excellent | Moderate (requires care) |

| Cost | Lower | Higher |

| Ideal Application | General refinery/petrochem | Offshore, sour service |

| Standards Compatibility | ASME B31.3, EN 10216-5 | NACE MR0175/ISO 15156 |

When to Use ASTM A312

Choose A312 tubes when:

- Operating temperatures exceed 500°C

- Corrosive media is oxidizing (e.g., nitric acid)

- High formability or bending is needed

- Project budgets are constrained

Typical Projects: Natural gas separation, LNG terminals, sulfur recovery units.

When to Use ASTM A789

Choose A789 tubes when:

- Chloride content is high (e.g., seawater, brine)

- Mechanical strength is a priority

- Compliance with NACE MR0175 is mandatory

- You need thinner walls for same pressure rating

Typical Projects: Offshore oil production, subsea manifolds, FPSO heat exchangers.

DLSS Manufacturing Capability

DLSS offers:

- ASTM A312 tubes: in 304L, 316L, 321, 347, 904L

- ASTM A789 tubes: in S31803, S32205, S32750, pickled or bright-annealed

- U-bent tubes, cut-to-length, and coiled tubing

- 100% Eddy Current / UT / Hydrostatic tests

- Full MTC EN 10204 3.1 / 3.2, NACE compliance

Conclusion

ASTM A312 and A789 serve distinct roles in the oil & gas pipeline and process industries:

- Use A312 for general austenitic stainless piping

- Use A789 for superior strength and sour service protection

DLSS helps you navigate both standards with precision manufacturing, full documentation, and global shipment support.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need help selecting between A312 and A789? Our technical team is ready to assist with specification and sourcing advice.