Meta Description:

Explore how ASTM A789 S32750 Super Duplex stainless steel tubes are used in seawater condensers, offering unmatched resistance to corrosion, pitting, and stress cracking in marine environments.

Introduction

Seawater condenser systems operate in highly aggressive environments, constantly exposed to chloride ions and variable temperatures. Standard stainless steels like 304 or 316 often fail due to pitting corrosion, crevice corrosion, and stress corrosion cracking (SCC).

To meet the demands of such harsh conditions, engineers turn to Super Duplex stainless steel, specifically ASTM A789 UNS S32750—a high-performance alloy known for superior strength and corrosion resistance.

What is ASTM A789 S32750?

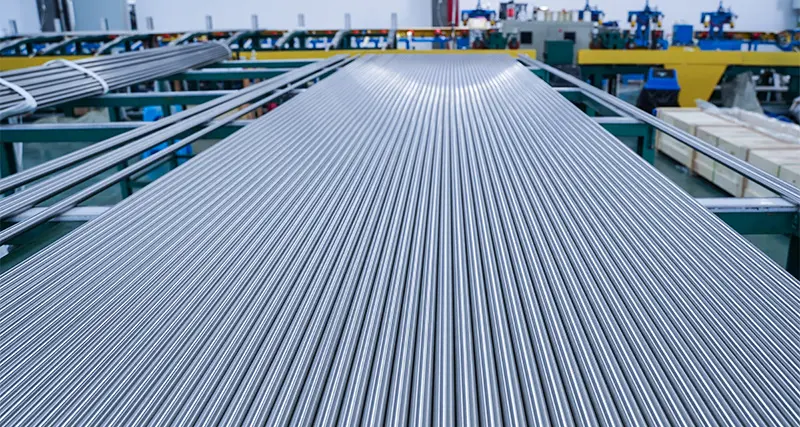

ASTM A789 covers seamless and welded tubes made from ferritic/austenitic stainless steels (Duplex), including the Super Duplex grade S32750.

Chemical Composition of S32750 (%):

| Element | Min – Max |

|---|---|

| Chromium (Cr) | 24.0 – 26.0 |

| Nickel (Ni) | 6.0 – 8.0 |

| Molybdenum (Mo) | 3.0 – 5.0 |

| Nitrogen (N) | 0.24 – 0.32 |

| Carbon (C) | ≤ 0.03 |

| Iron (Fe) | Balance |

Key Features:

- PREN > 40 (Pitting Resistance Equivalent Number)

- Twice the yield strength of austenitic stainless steels

- Resistant to chloride-induced stress corrosion cracking (SCC)

- Excellent weldability with controlled ferrite-austenite phase balance

Why Use S32750 for Seawater Condensers

Seawater cooling systems, especially in coastal power plants, offshore oil platforms, and desalination plants, require tubing that can:

- Resist localized corrosion in high chloride environments

- Withstand internal pressure and thermal cycling

- Maintain mechanical integrity over long service life

S32750 excels in all these aspects, making it a preferred material for:

- Shell & tube heat exchangers

- Seawater-cooled condensers

- Evaporator tubing

- Cooling water intake lines

Typical Tube Specification from DLSS

- Standard: ASTM A789

- Grade: S32750 (UNS S32750 / 1.4410)

- Tube Size: 19.05 mm OD × 1.65 mm WT × 6100 mm

- Type: Seamless, cold-drawn

- Surface: Bright Annealed (BA) or Pickled & Passivated

- Delivery Condition: Solution Annealed and tested

- Inspection:

- 100% Eddy Current Testing (per ASTM E426)

- Hydrostatic Test

- PMI (Positive Material Identification)

- Intergranular Corrosion Test (per ASTM A262 Practice E)

- Ferrite content control (20–35%)

Industry Applications

| Sector | Application |

|---|---|

| Power Generation | Seawater-cooled steam condensers |

| Desalination | Brine heaters, condenser tubing |

| Marine & Offshore | Cooling and heat recovery systems |

| Oil & Gas | Platform-based seawater heat exchangers |

| Chemical Plants | Chloride-rich cooling water circulation lines |

DLSS Testing and Compliance

All S32750 tubes supplied by DLSS are certified and inspected according to:

- ASTM A789 / ASTM A1016

- EN 10204 3.1 / 3.2 Test Certificates

- NACE MR0175 / MR0103 (upon request)

- ASME Boiler & Pressure Vessel Code (for pressure applications)

SEO Keywords

- ASTM A789 S32750 tube

- super duplex stainless steel pipe

- seawater condenser tubing

- high corrosion resistant tube

- S32750 vs 316L

- duplex heat exchanger tube

- super duplex for desalination plant

- UNS S32750 seamless pipe

- ASTM A789 super duplex tube supplier

- marine-grade duplex stainless steel

Contact DLSS for Super Duplex Tubing Solutions

Need a reliable supplier of ASTM A789 S32750 seamless tubes?

We offer short lead times, competitive pricing, and full documentation for EPC, marine, and power plant projects.

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Let DLSS be your trusted pipeline solution partner for the harshest environments.