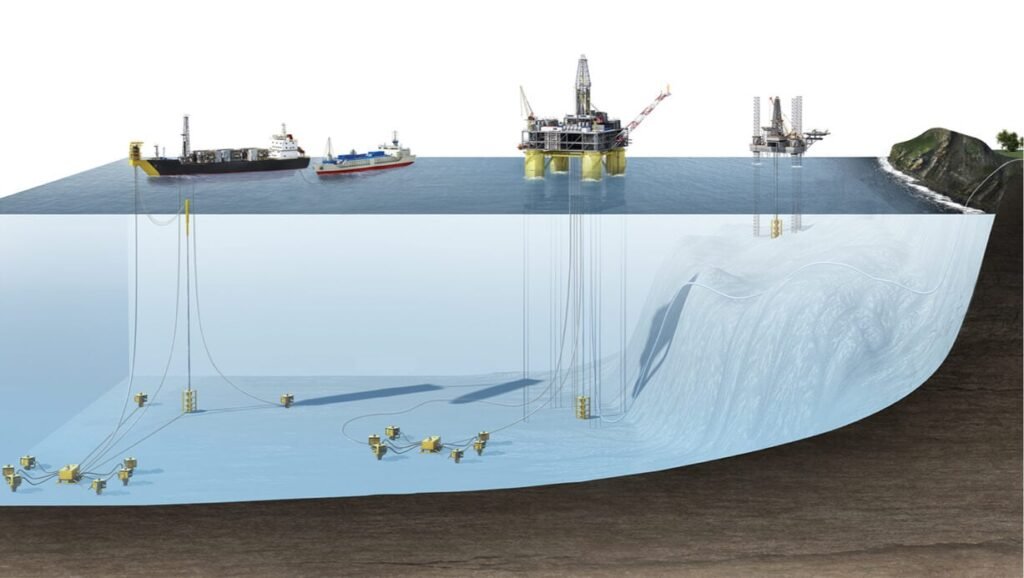

Offshore oil and gas platforms operate in some of the harshest environments on earth—intense humidity, salt spray, hydrogen sulfide, and high-pressure processes. These conditions make corrosion the #1 threat to heat exchanger systems and piping reliability.

To reduce failures and maintenance costs, operators are turning to advanced stainless steel and duplex alloy tubes as the core solution for offshore heat exchangers.

1. The Offshore Corrosion Challenge

Key corrosion risks on offshore rigs include:

- Seawater corrosion (pitting, crevice attack) from open-loop cooling systems

- Sour service (H₂S exposure) in gas dehydration and amine units

- Stress corrosion cracking (SCC) due to high chloride and thermal cycling

- Galvanic corrosion when dissimilar metals are used in bundle assemblies

According to DNV, corrosion-related failures account for over 30% of unplanned downtime in offshore operations—much of it related to cooling, separation, or utility systems.

2. Where Heat Exchanger Tubes Are Used Offshore

| Application Area | Tube Function |

|---|---|

| Crude oil coolers | Reduce temperature before separation or export |

| Gas dehydration units | Heat and reboil glycol or amine solutions |

| Seawater-cooled condensers | Condense process gases using seawater |

| Closed-loop platform cooling | Remove heat from compressors, turbines, or control rooms |

3. Materials That Outperform in Offshore Conditions

Austenitic Stainless Steel (TP316L / TP317L)

- Used in moderate chloride environments (≤1000 ppm)

- Easy to fabricate and weld

- Pickled and passivated for enhanced corrosion resistance

Duplex Stainless Steel (S32205 / S32750)

- Higher strength and chloride pitting resistance (PREN > 35)

- Suitable for seawater, brine, and amine-rich systems

- Often used in accordance with NORSOK M-630

Super Austenitic / Nickel Alloys (904L / 625)

- For ultra-aggressive or sour gas conditions

- High Ni-Mo-Cr content to resist crevice and pitting corrosion

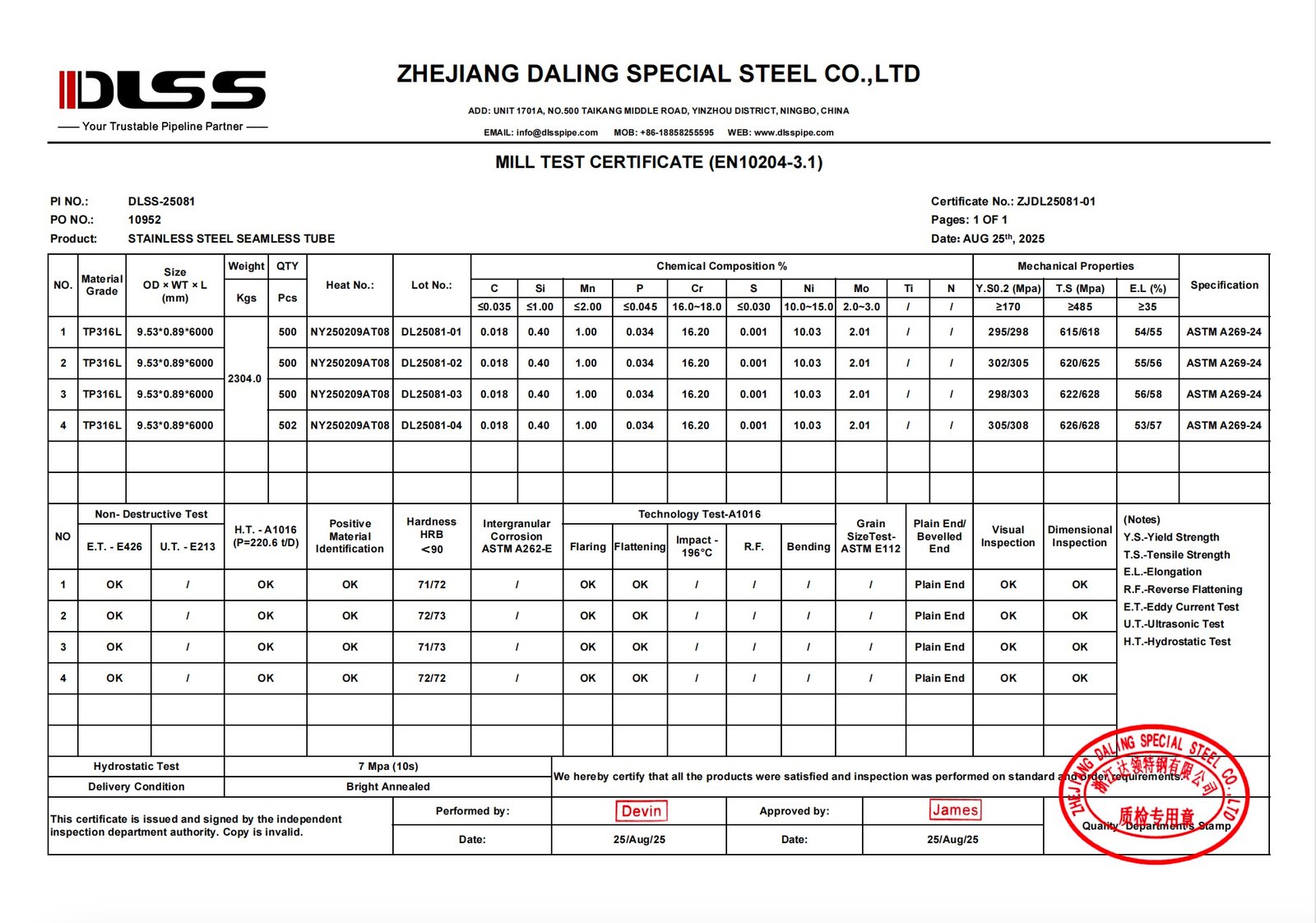

4. What Offshore Operators Expect from Tube Suppliers

| Requirement | Details |

|---|---|

| NDT reports | 100% eddy current, hydrostatic or air under water testing |

| Heat treatment | Solution annealing + passivation |

| EN 10204 3.2 / Third-party inspection | Required by many IOCs and offshore EPCs |

| Project traceability | Full control from melt to final shipment |

| Marking and seaworthy packaging | Bundle tags, alloy identification, anti-corrosion wrapping |

Suppliers who support early involvement in material selection, engineering drawings, and inspection plans often win long-term contracts.

5. DLSS Capabilities

DLSS offers duplex and austenitic stainless tubes specifically engineered for offshore heat exchanger systems. Our products are 100% tested, PED/ASME certified, and seaworthy packed with full traceability. We’ve supported offshore projects in UAE, Norway, and Malaysia with finned U-tubes, straight bundles, and seawater-grade alloys.

Frequently Asked Questions (FAQ)

Q1: What’s the best stainless steel grade for seawater-cooled heat exchangers?

A: For temperatures below 60°C, S32205 (duplex) is excellent. For higher temperatures or aggressive conditions, S32750 or 904L is preferred.

Q2: Do all offshore projects require EN 10204 3.2 certificates?

A: Many do—especially when supplying to European oil majors (e.g., Equinor, TotalEnergies). Check tender specifications.

Q3: Can DLSS handle small-batch or urgent offshore projects?

A: Yes. We can support flexible MOQ, expedited production, and third-party inspections for shutdown or emergency projects.

Q4: How are tubes protected during marine shipment?

A: Tubes are capped, wrapped in VCI film or oil paper, bundled with alloy tags, and loaded in fumigated wooden crates or steel racks.

Conclusion: Strong Tubes for Rough Waters

Offshore operations don’t forgive weak materials. From FPSOs to gas dehydration skids, every tube must resist corrosion, thermal stress, and failure under pressure.

With the right alloy, treatment, and documentation, stainless steel tube manufacturers can become strategic partners—not just suppliers—in offshore energy’s most critical systems.

The future of energy lies partly at sea—and the right tube makes that future possible.