Meta Description:Choosing pipe material can make or bre […]

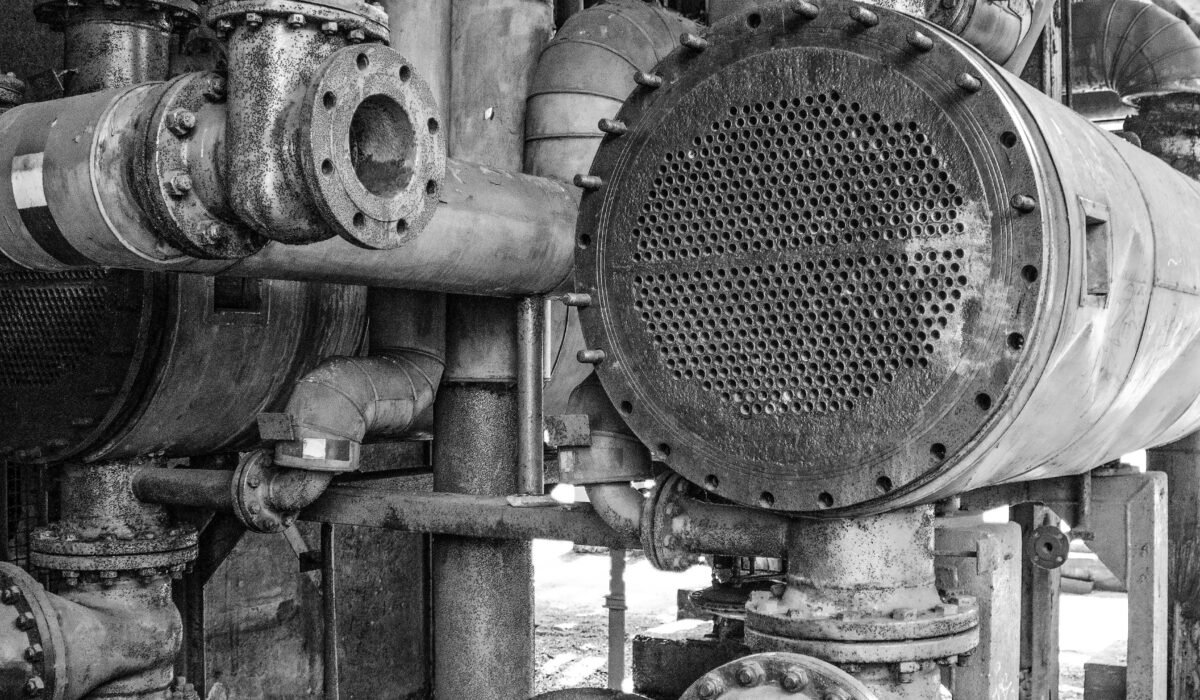

Read MoreOne-stop solution for heat exchanger

Customized for Every Heat Exchanger

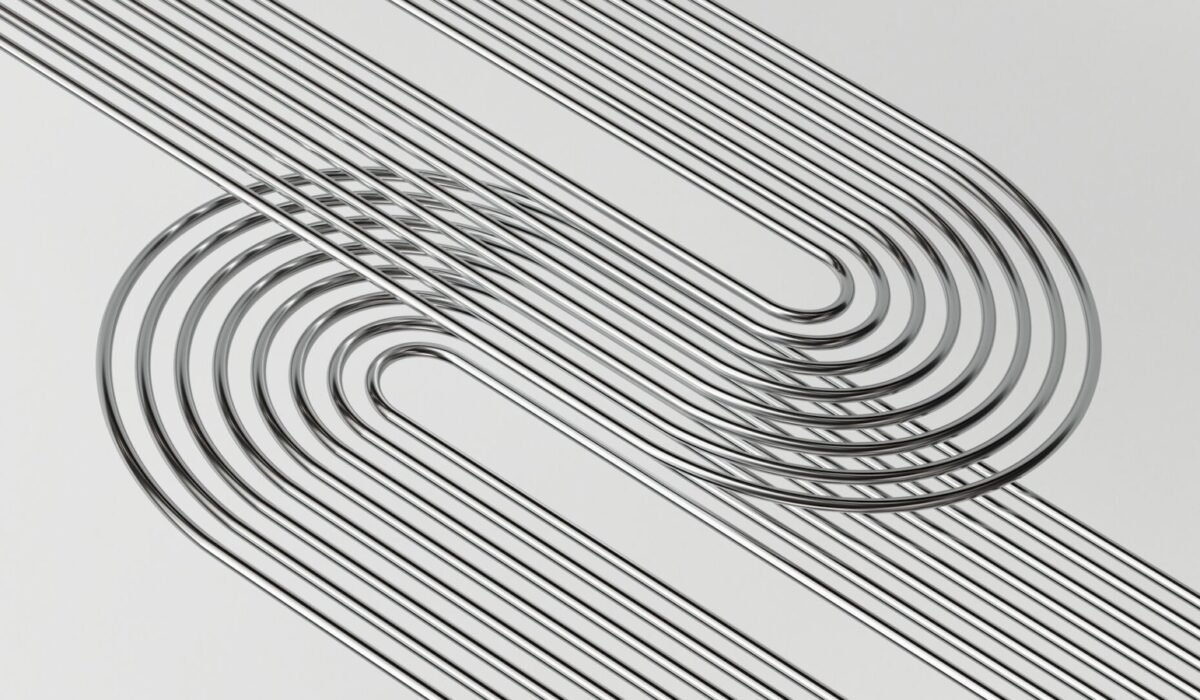

U-Tubes for Heat Exchanger

High heat transfer efficiency, compact structure, easy maintenance, thermal expansion accommodation, design flexibility, durability, and cost-effectiveness are the advantages of U-tube heat exchangers produced by DLSS.

Pickling tubes for Heat Exchanger

Enhanced corrosion resistance and cost-effectiveness provide our pickling tubes with greater market competitiveness, making them ideal for heat exchanger production with durability and long service life.

Bright tubes for Heat Exchanger

Smooth surfaces reduce fluid adhesion, minimize cleaning, enhance heat transfer, and extend heat exchanger life, making our bright tubes ideal for heat exchanger production.

Finned tubes for Heat Exchanger

High heat transfer efficiency, durability, and corrosion resistance make our fin tubes ideal for heat exchanger applications.

Tube Sheets for Heat Exchanger

Ensures secure tube placement and optimal heat transfer through precision-engineered tube sheets for heat exchangers.

Flanges for Heat Exchanger

Ensures secure connection and pressure sealing through precision-engineered flanges for heat exchangers.

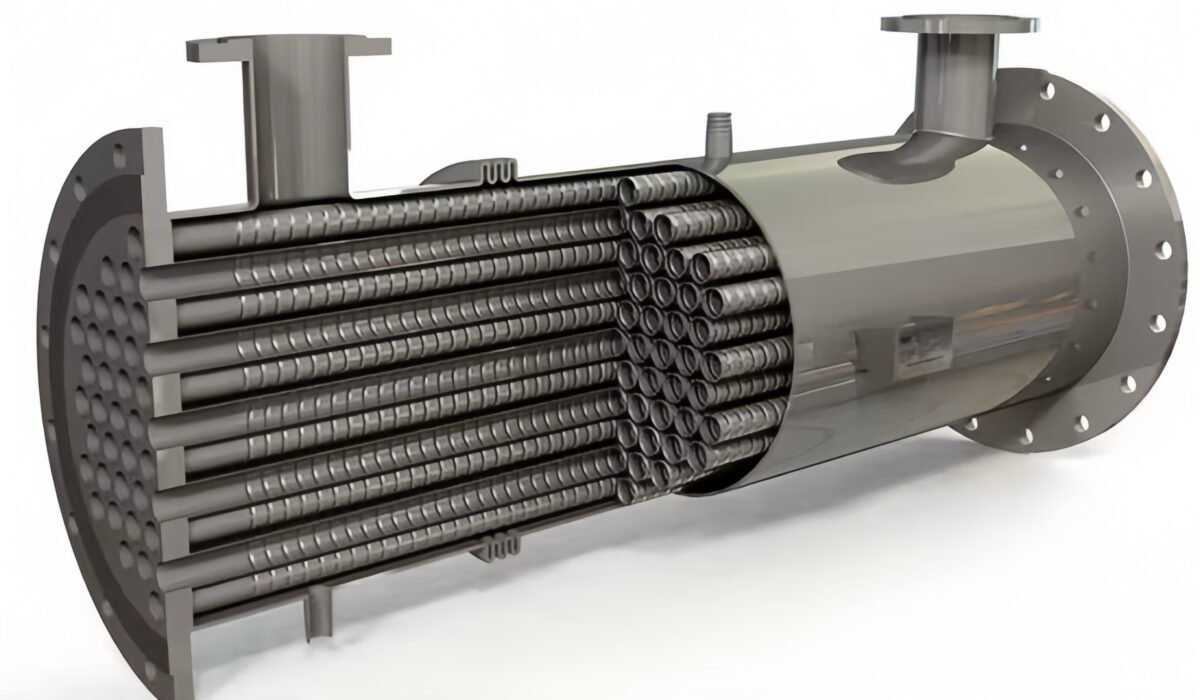

tube bundle for Heat Exchanger

Engineered for precision and performance — our tube bundles ensure secure tube alignment and maximize heat transfer efficiency in every heat exchanger.

High-Performance Stainless Steel Tubes for Heat Exchanger Applications

DLSS Partners

Jn S***h

As a heat exchanger manufacturer, we often face urgent orders from our customers. In one particular project, we had an extremely tight deadline and struggled to find stainless steel tubes that met our specifications. DLSS responded quickly, arranged production in record time, and coordinated the best logistics plan to ensure on-time delivery. Their efficiency and professionalism left a lasting impression on us, and we look forward to a long-term partnership with DLSS!

Mk B***r

Our heat exchanger products operate under high pressure and high temperatures, requiring stainless steel tubes with exceptional precision and corrosion resistance. The materials supplied by DLSS not only met our strict technical requirements but even exceeded our expectations. With their rigorous quality control and reliable management, they helped us maintain product stability and gain the trust of our end customers. DLSS is a partner we can truly rely on!

Aa D***s

One of our heat exchanger designs required stainless steel tubes in non-standard dimensions, which were difficult to source in the market. After discussing our technical requirements, DLSS quickly adapted their production process and delivered tubes that precisely met our specifications. Their flexibility and expertise ensured the smooth launch of our product. DLSS stands out as a top-tier supplier in the industry!

Ty W***n

During one of our production runs, we encountered issues with the weldability of a batch of raw materials, which posed a risk to our final product quality. The technical team at DLSS promptly stepped in, analyzed the problem, and provided professional recommendations. By optimizing material selection and processing techniques, they helped us completely resolve the issue. DLSS is more than just a supplier—they are a valuable technical partner we can depend on.

John D.*

We have been working with DLSS for years, starting with small-volume purchases and gradually expanding to large-scale collaborations. Every time, we experience their professionalism and dedication. Whether it's order adjustments, quality control, or urgent deliveries, DLSS consistently provides the best solutions, helping our business grow steadily. A supplier like DLSS is not just reliable but truly indispensable for long-term success!

From Every Part of The tube…

We care about the quality of stainless steel tubes. That’s why we focus on every detail of every component to ensure durability, precision, and superior performance.

Ensures material accuracy and dimensional precision through chemical composition testing (verified by PMI and spectrometer) and size measurement (including OD, WT, length, and pipe end).

Ensures dimensional accuracy and proper fit through ring gauge testing.

Ensures strength and leak-proof performance under specified pressure conditions through hydrostatic testing.

Ensures detection of surface cracks and defects through Penetrant Testing (PT).

Ensures internal surface quality and detects internal defects through borescope (endoscope) inspection.

Ensures surface quality and detects external defects through external surface inspection.

Dedicated Support for Seamless Integration

Accurate ordering

Accurately and clearly, we input all order details, including the customer's special requirements, into our internal system to prevent any errors after production is scheduled.

Production Control

Each order is assigned a unique tracking number to ensure meticulous management, with every stage strictly recorded and signed for full traceability. Comprehensive inspections, including HT, ET, UT, RT, and PT, are conducted to guarantee superior performance and quality.

After-sales service

Responsive After-Sales Service, Offering Free Exchange or Replenishment of Your Stainless Steel Tubes to Ensure High-Quality Heat Exchanger Installation and Timely Order Fulfillment.

Technical Support

Technical support is provided promptly via phone, email, and online chat to efficiently address your technical issues and inquiries.

In-Depth FAQs: Solving Your Heat Exchanger Tube Problems

What's your Min Order Quantity (MOQ)?

1PC. (Except for the special material and size)

What's your delivery?

5~60 Days. (Depends on products and quantity)

How do you ensure good quality?

Each order production finished we arrange double Inspection and submit all photos and videos for client’s approval. Besides, we accept Third Party Inspection before shipment.

How about your payment term?

T/T or LC at sight. (Deposit is required)

Can you provide FREE sample?

Yes. (If special material or size, let’s discuss in detail)

How long is the warranty period?

Normally three years. (Negotiable)

Company News

How to Pass PMI, ET, and IGC

Meta Description:Learn how stainless steel tubes are te […]

Read MoreUnderstanding ASTM A213 – Seamless Tubes for

Meta Description:Learn everything about ASTM A213: scop […]

Read MoreSeamless vs Welded Stainless Steel Pipes: Which

Meta Description:Seamless or welded pipe? Learn the str […]

Read MoreWelcome To Send Us An Inquiry,

We Have Prepared A Surprise Gift For You