With water scarcity on the rise, seawater desalination has become a critical infrastructure priority—especially in the Middle East, North Africa, Asia-Pacific, and parts of Latin America. These plants rely heavily on heat exchanger systems for energy-efficient freshwater production.

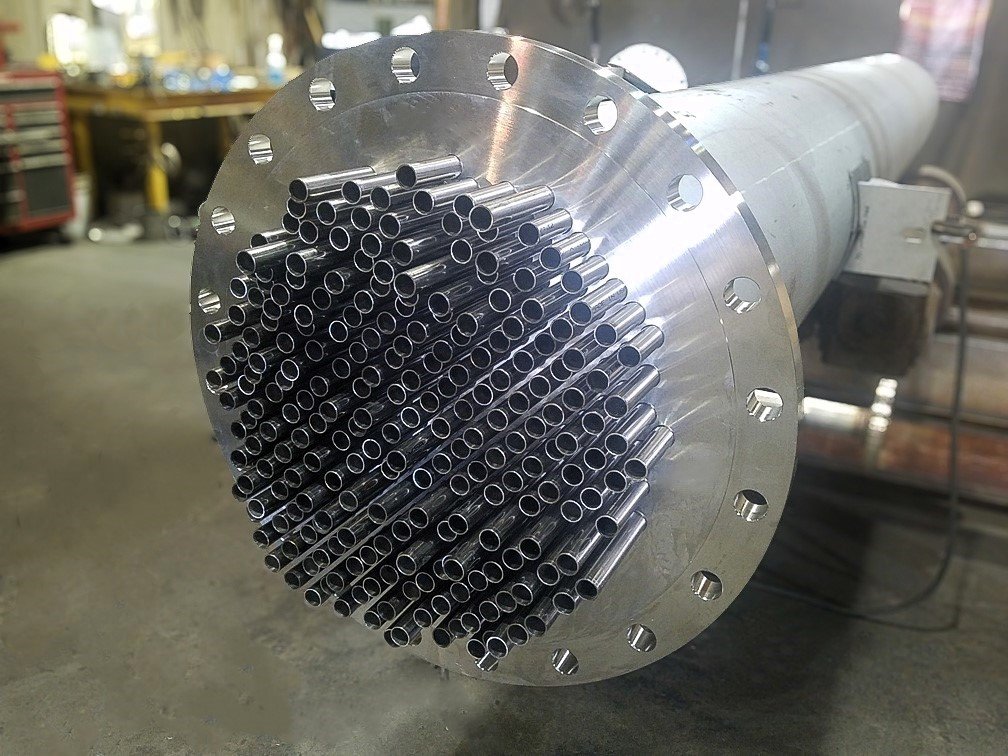

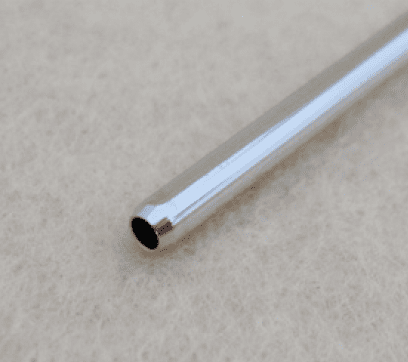

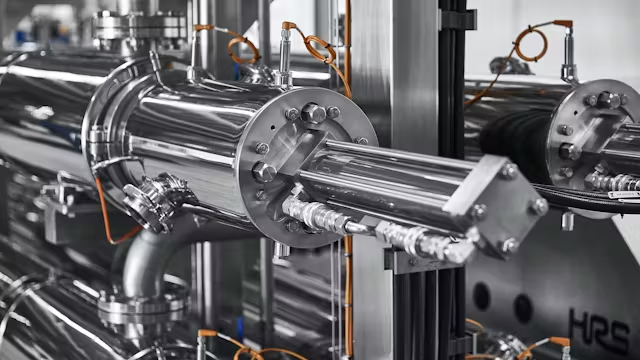

And at the core of those systems? Stainless steel tubes that can withstand aggressive chloride-rich environments, pressure fluctuations, and long service cycles without failure.

1. Why Desalination Is Booming

- Over 21,000 desalination plants are operational worldwide

- Most use multi-effect distillation (MED) or reverse osmosis (RO) systems

- Exposure to salts, sulfates, bacteria, and pressure cycling causes rapid corrosion in inferior materials

- Desalination now provides over 40% of municipal water in countries like UAE, Saudi Arabia, and Israel

Source: International Desalination Association (IDA)

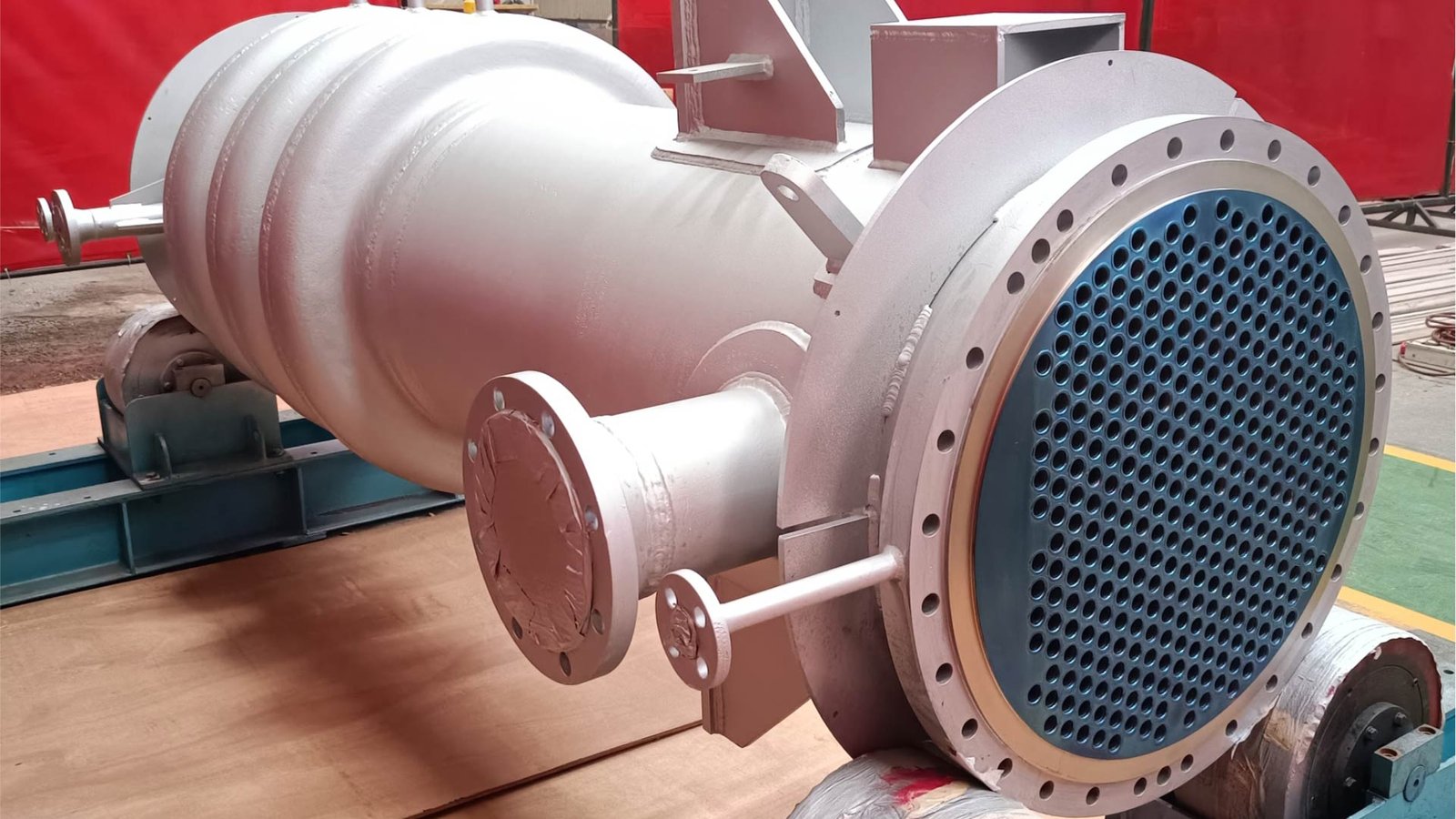

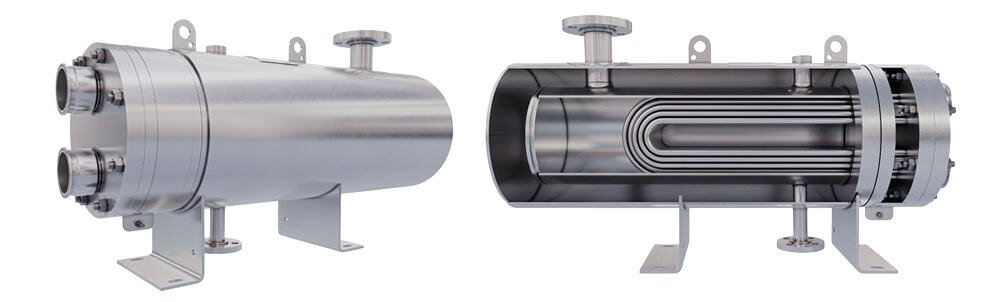

2. Where Stainless Steel Tubes Are Used in Desalination Systems

| System | Tube Requirement |

|---|---|

| Brine heater / condenser | Seamless or welded TP316L / S32205 with smooth ID |

| Thermal vapor compressors | High-pressure tubes, wall thickness control |

| Energy recovery systems (ERD) | Corrosion-resistant duplex grades |

| RO pretreatment heat exchangers | High-purity low-S iron with passivated finish |

| Concentrate cooling modules | Anti-scaling, pickled & passivated tubes |

In MED and MSF (multi-stage flash) systems, tubing must endure saline vapor condensation, temperature gradients (60–120°C), and scale deposition.

3. What Grades Are Most Common?

| Grade | Use Case | Advantage |

|---|---|---|

| TP316L | Basic thermal desalination | Affordable, easy to fabricate |

| S32205 (duplex) | High-chloride brine areas | Pitting resistance equivalent (PREN > 35) |

| S32750 / 904L | Extended-lifecycle condensers | High Mo and Cr, anti-microbial |

| 254SMO / Alloy 625 | Ultra-aggressive RO conditions | Premium seawater alloy, 20+ year lifespan |

DLSS supplies SA213 / EN10216-5 compliant tubes for global desalination EPCs and operators, with full material certification, PMI, and seaworthy packaging.

4. What EPC Contractors and End Users Require

| Requirement | DLSS Offering |

|---|---|

| Full traceability | Heat number, MTC, hydro test report |

| 3.1 / 3.2 certificates | With BV / SGS / TUV third-party endorsement |

| Seamless or TIG-welded tubes | For low fouling, easy cleaning |

| Low surface roughness (Ra ≤ 0.6 μm) | Enhances heat transfer, limits scaling |

| Export packaging | PE caps + VCI film + seaworthy crate + tube tags |

DLSS also supports pre-bundling of tube lengths, multi-alloy shipments, and custom engraving or color coding.

Frequently Asked Questions (FAQ)

Q1: Why is duplex stainless steel popular in desalination plants?

A: It offers a better strength-to-weight ratio and higher resistance to pitting, crevice, and stress corrosion cracking in chloride-heavy environments.

Q2: Are seamless or welded tubes preferred in MED desalination?

A: Both are used depending on budget and system design. Welded TP316L may be chosen for lower cost; seamless S32205 for durability and low fouling.

Q3: What standards are required for desalination tube supply?

A: ASTM A213 / A789 / EN10216-5, ASME Section VIII, and often EN 10204 3.2 certification for large EPC tenders.

Q4: Can DLSS ship mixed-grade tube orders?

A: Yes. We routinely ship multi-grade orders (e.g., TP316L + duplex) with distinct tagging, packaging, and MTC sets.

Conclusion: In Desalination, Tube Failure Is Not an Option

From Saudi Arabia’s massive Jubail plant to Chile’s copper mining water systems, desalination heat exchangers must operate non-stop, without corrosion, for decades.

That’s why stainless steel tubes—sourced, inspected, and certified correctly—are essential to plant success.

At DLSS, we support desalination projects with the right material, precision manufacturing, and global documentation support—so you can build freshwater reliability from the inside out.