Meta Description:

Pickled or bright annealed? Learn the pros, cons, and applications of these two surface treatment methods used in stainless steel tube manufacturing.

Introduction

The performance of stainless steel tubes isn’t just about alloy grade or dimensional accuracy—surface finish plays a crucial role in corrosion resistance, cleanliness, and long-term durability.

Two widely used surface treatments are:

- Pickling (Acid Cleaned)

- Bright Annealing (BA)

Each has distinct characteristics, advantages, and ideal applications. This article explores their differences and helps you decide which finish is most suitable for your industrial or hygienic systems.

What Is Pickling?

Pickling is a chemical process that removes:

- Oxide scale

- Welding discoloration

- Surface contaminants

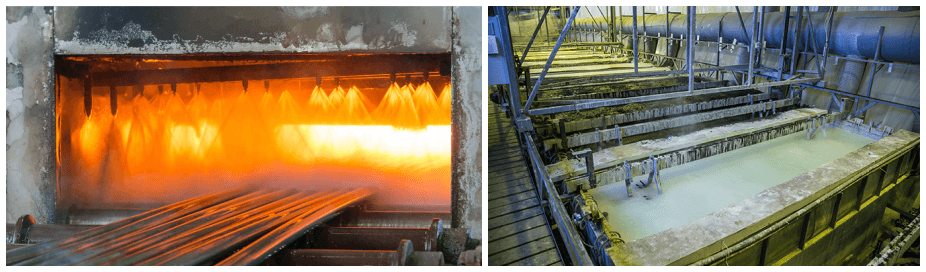

How It Works:

- Tubes are immersed in a mixture of nitric and hydrofluoric acids

- Oxide layers formed during hot forming or welding are dissolved

- A passive chromium-rich layer reforms after rinsing

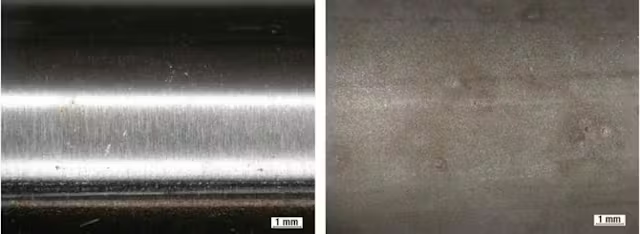

Resulting Appearance:

- Matte, dull gray surface

- Uniform, clean but slightly rough texture

Benefits:

- Removes embedded iron, carbon deposits, and heat tint

- Restores corrosion resistance

- Cost-effective for industrial-grade tubing

Standards Involving Pickled Finish:

- ASTM A269 (pickled or polished)

- ASTM A213 (solution-annealed + pickled)

- EN 10216-5 TC1/TC2

Learn more about pickling from Outokumpu’s surface finish guide

What Is Bright Annealing (BA)?

Bright annealing is a heat treatment process performed in a controlled reducing atmosphere (usually hydrogen or nitrogen/hydrogen mixture) to achieve:

- Recrystallization of grains

- Stress relief

- Oxide-free surface

How It Works:

- Tubes are annealed at 1050–1150°C

- Cooling is rapid under inert gas

- No acid pickling is required post-treatment

Resulting Appearance:

- Mirror-like, reflective surface

- Extremely smooth and clean

Benefits:

- Ideal for hygienic applications (food, pharma, biotech)

- Low Ra value (≤0.5 μm), suitable for CIP/SIP systems

- Better resistance to particle adhesion and fouling

- Often meets ASME BPE and 3-A Sanitary Standards

Reference: ASME BPE Standard Overview

Pickling vs Bright Annealing: Side-by-Side Comparison

| Feature | Pickled Surface | Bright Annealed Surface |

|---|---|---|

| Appearance | Dull gray, matte | Shiny, mirror-like |

| Roughness (Ra) | ~1.2 – 3.2 μm | ~0.3 – 0.5 μm |

| Ideal Application | Heat exchangers, power plants | Food, pharma, cleanrooms |

| Corrosion Resistance | Moderate | Excellent (no oxide scale) |

| Cost | Lower | Higher (special furnace needed) |

| Weld Seam Removal | Yes | No (unless polished separately) |

| Cleanability | Good | Superior |

| Industry Standards | ASTM A269 / A213 | ASTM A270 / ASME BPE |

When to Choose Pickled Tubes

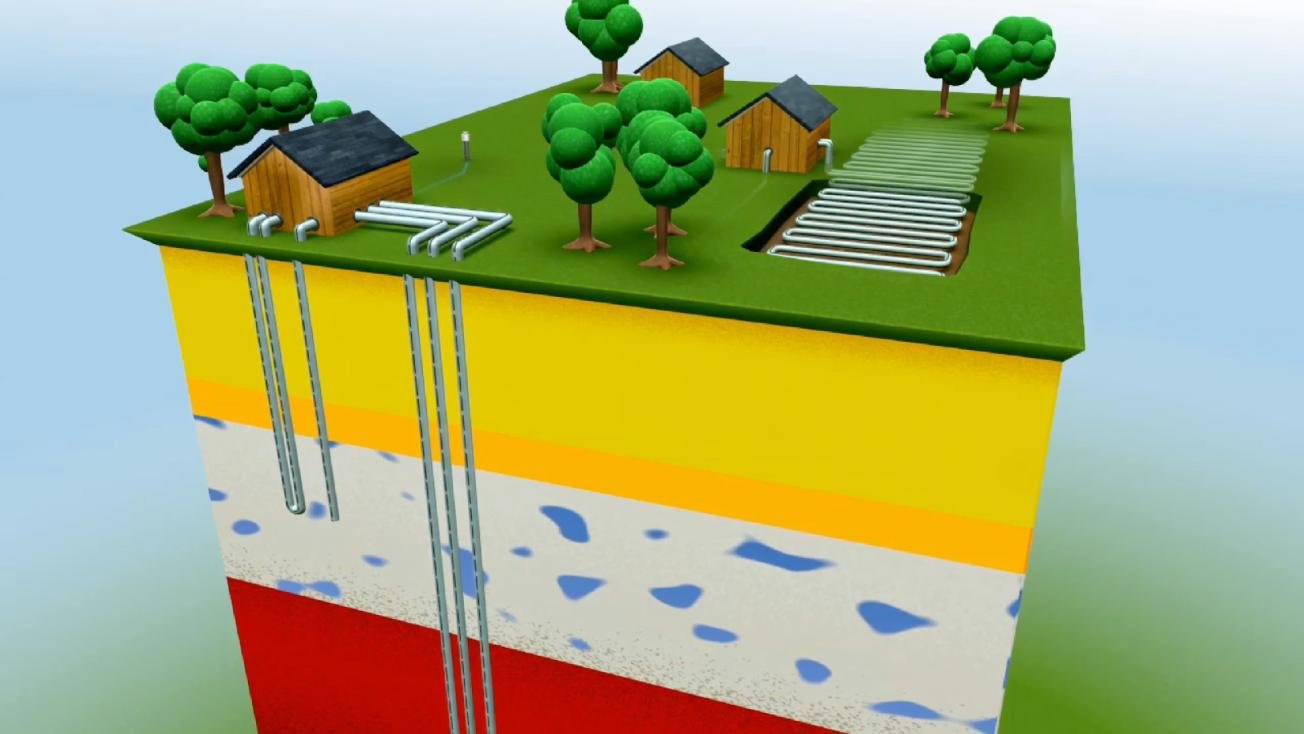

- Power boiler and refinery heat exchangers

- General industrial piping

- Non-hygienic systems

- Projects with tight budgets

- Applications involving painting, galvanizing, or cladding

When to Choose Bright Annealed Tubes

- Dairy, brewery, beverage, and pharmaceutical plants

- Semiconductor-grade water systems

- UHT sterilizers and heat exchangers in sterile environments

- Client requires electropolishing (BA is the base surface)

DLSS Surface Finish Capabilities

We offer:

- Pickled Seamless Tubes in TP304L, TP316L, TP321, and Duplex

- Bright Annealed Tubes with Ra ≤ 0.5 μm, available in long length or U-bent

- Optional inner polishing, ID buffing, or EP (Electropolishing)

- Full test reports with surface finish measurements and MTC EN 10204

Whether your priority is corrosion protection or sanitary perfection, we have a finish to match.

Conclusion

The right surface treatment for stainless steel tubes depends on your industry, performance expectations, and regulatory requirements.

- Use pickling for structural and high-temperature applications

- Choose bright annealing for ultra-clean, hygienic systems

DLSS provides both solutions with quality control, documentation, and global export expertise.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Not sure which surface treatment your application needs? Our engineers are ready to advise.