Why Sanitary Tubing Matters in Food and Beverage Systems

In the food and beverage industry, stainless steel tubing is not just about mechanical performance—it’s about hygiene, cleanliness, and compliance. Tubes are used to transport milk, beer, juice, water, or cleaning agents in systems that demand zero contamination, excellent cleanability, and corrosion resistance.

Improper material selection can lead to biofilm buildup, corrosion from acidic products, or failure under frequent cleaning cycles (CIP/SIP). Therefore, choosing the correct sanitary-grade stainless steel tube ensures food safety, long service life, and regulatory compliance.

Recommended Stainless Steel Tubes for Hygienic Applications

1. TP304 / TP304L — General Purpose Food-Grade Tube

- Low carbon for better weld integrity

- Suitable for low-acidity products like water, milk, beer

- Compliant with ASTM A270, EN 10357, 3-A Sanitary Standard

2. TP316L — Acid & Chloride Resistant Sanitary Tube

- Ideal for acidic juice, wine, fermented products, and brine

- Excellent resistance to cleaning chemicals and salty environments

- Widely used in dairies, breweries, meat processing plants

3. EN 1.4404 / DIN 1.4435 — European Hygienic Tube Grades

- Tighter control on sulfur and surface finish

- Polished or electropolished for ultra-clean environments

- Common in pharmaceutical and high-purity food systems

4. 904L / 254SMo — High-Resistance Tubes for Aggressive CIP Media

- Superior performance against high concentrations of acids and chlorides

- Used in cleaning loops, acid dosing lines, or where long cleaning cycles apply

- Over-engineered but ideal for high-end processing plants

Key Criteria for Sanitary Stainless Steel Tubes

| Parameter | Importance in Food & Beverage Systems |

|---|---|

| Surface Roughness (Ra ≤ 0.8 µm) | Prevents bacterial retention and biofilm formation |

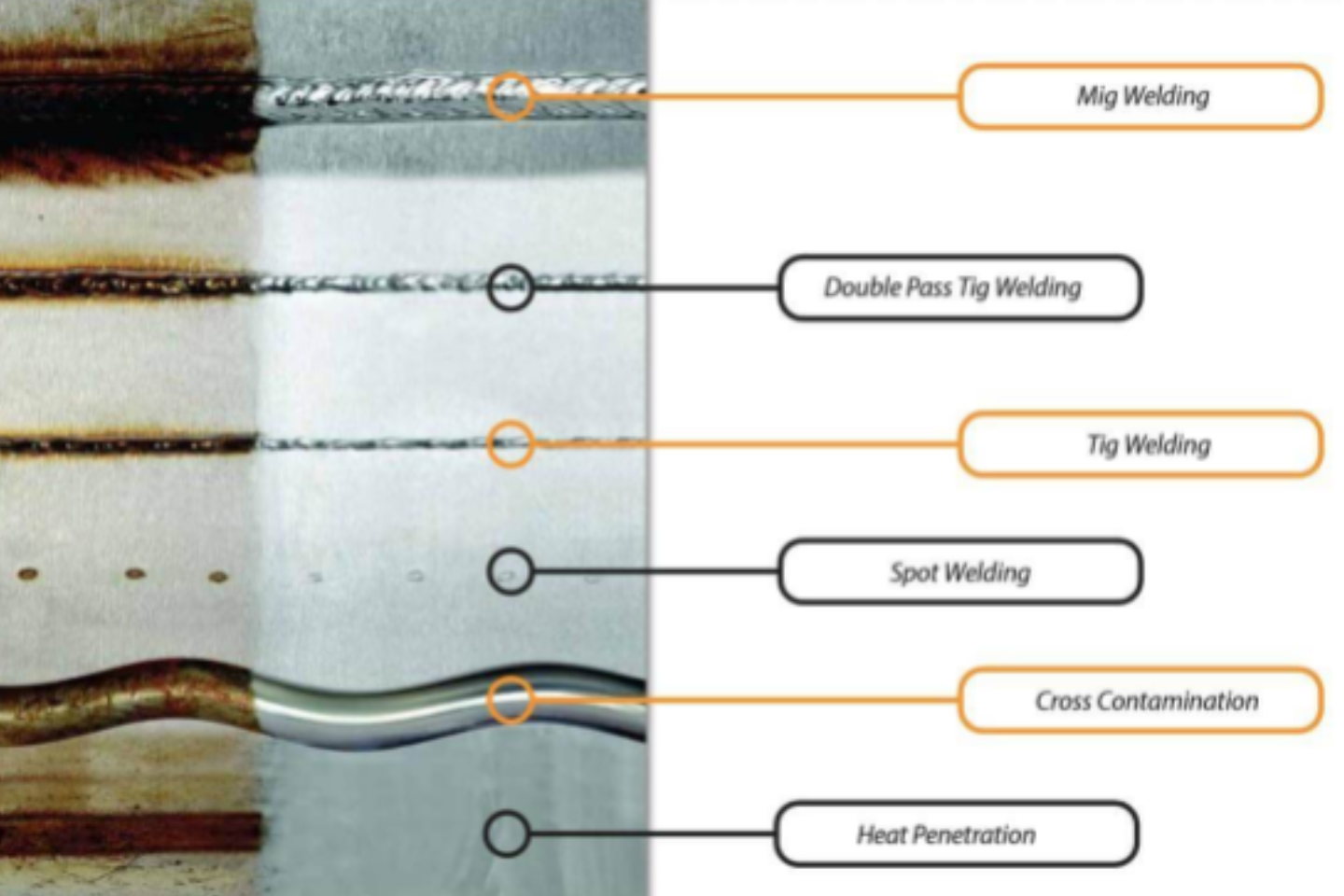

| Weldability & Orbital Welding Suitability | Ensures sterile joints and clean-in-place efficiency |

| Corrosion Resistance | Withstands food acids, alkaline cleaners, and saline media |

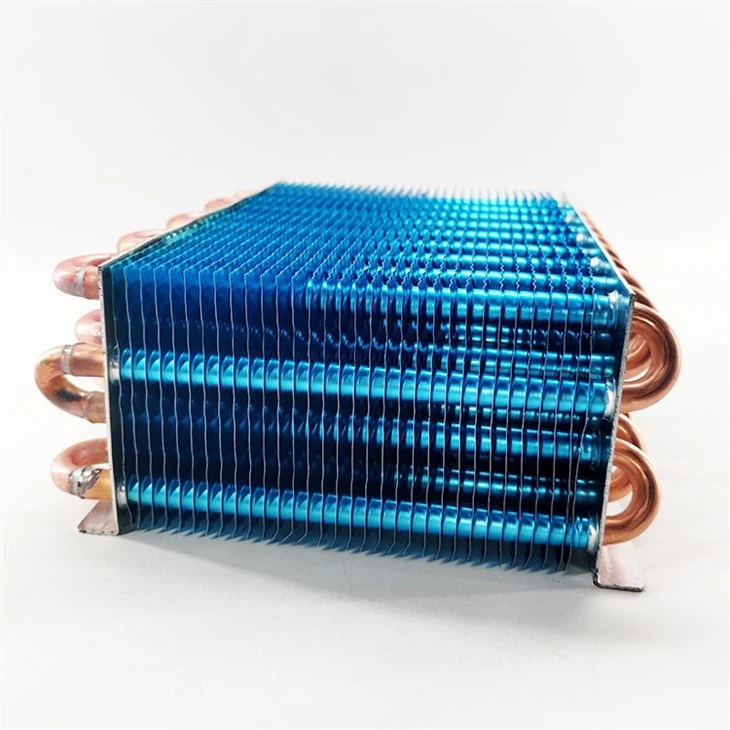

| Polish or Electropolish Finish | Required for dairy, juice, brewing, and pharma lines |

| Compliance Standards | ASTM A270, 3-A, ISO 2037, EN 10357, FDA, EHEDG |

Global Trends in Hygienic Tubing (2025 Update)

- Southeast Asia and Latin America are upgrading dairy and beverage plants to fully welded 316L sanitary tube systems

- Craft beer and juice producers increasingly demand polished tubes with Ra ≤ 0.6 μm to prevent yeast/bacteria buildup

- EU and USA regulatory tightening is boosting adoption of 3-A and EHEDG compliant tubing

DLSS Expert Insight

“In hygienic systems, surface finish is everything. A highly polished 316L tube with good welds can outperform exotic alloys if installed correctly. We advise customers on both grade and finish selection for each food process line.”

— DLSS Sanitary Application Engineer

Frequently Asked Questions (FAQ)

Q1: What’s the difference between A269 and A270 tubes?

A270 has stricter control on surface finish and is used in sanitary applications. A269 is general industrial-grade.

Q2: Can I use 304 in a wine or vinegar process line?

304 is suitable for basic food contact, but for acidic or brine-based media, 316L is strongly recommended.

Q3: What Ra value is needed for hygienic stainless steel tubing?

Typically Ra ≤ 0.8 μm, and in pharmaceutical or fermentation lines, Ra ≤ 0.6 μm or electropolished is preferred.

Conclusion: Hygienic Design Starts with the Right Tube

When it comes to food and beverage processing, product safety starts at the pipe level. DLSS provides sanitary stainless steel tubing with smooth, clean surfaces, full traceability, and global compliance.

From milk to beer, juice to brine—we help your system stay clean, corrosion-free, and fully certified for international export or local compliance.