Why Cryogenic Environments Demand Specialized Tubing

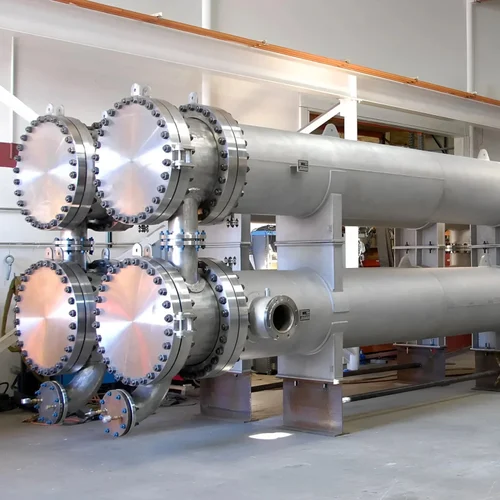

Cryogenic systems, such as LNG pipelines, vaporizers, and storage tanks, operate at extremely low temperatures — sometimes below –196°C. In such harsh conditions, stainless steel tubes must retain excellent mechanical strength, ductility, and impact toughness.

Incorrect tubing materials in LNG systems can lead to brittle fracture, thermal fatigue, or sudden pipeline failure. That’s why selecting cryogenic-grade stainless steel tubes is essential to ensure performance, safety, and long-term reliability in LNG and low-temperature process systems.

Best Stainless Steel Grades for LNG and Cryogenic Tubing

1. 304L / 304LN Stainless Steel Tube

Low-carbon and nitrogen-enhanced austenitic stainless steels, widely used in LNG storage tanks and cryogenic pipelines.

- Excellent impact resistance at low temperatures

- Good weldability and corrosion protection

- Compliant with ASTM A312 / A358 / EN 10216-5

2. 316L / 316LN Stainless Steel Tube

The most commonly used tubing grade for LNG vaporizers and cryogenic processing plants.

- Superior resistance to chlorides and saline conditions

- Nitrogen enhances strength and cryogenic toughness

- Ideal for offshore LNG, coastal terminals, and marine bunkering

3. 321 Austenitic Stainless Steel Tube

Titanium-stabilized tubing ideal for cryogenic systems with cyclic heat loads.

- Strong resistance to sensitization and intergranular corrosion

- Used in LNG pump skids, cold box headers, and cyclic thermal systems

4. 310S / 347 Tubes for Dual Thermal Zones

Designed for LNG components facing both high and low temperature stresses.

- High-temperature oxidation resistance

- Stable performance in reboilers and dual-process cryogenic vessels

5. Nickel Alloy Tubes (Inconel 625, 825, C276)

Used in high-end LNG applications involving seawater, chlorides, or high-pressure environments.

- Superior stress corrosion cracking resistance

- High strength under extreme cold and pressure

- Best for subsea LNG, sour gas systems, and cryogenic heat exchangers

Selection Criteria for Cryogenic Stainless Steel Tubes

| Selection Factor | Cryogenic Relevance |

|---|---|

| Low-temperature Impact Toughness | Prevents brittle fracture at cryogenic temperatures |

| Controlled Ferrite Content | Ensures austenitic phase stability in cryo environments |

| Clean Inner Surface & Degreasing | Required for LNG and oxygen-rich cryogenic gases |

| Weldability and Fabrication | Affects on-site integrity and performance under low temperatures |

| Compliance Standards | ASTM A312, A358, A269, ASME B31.3, EN 10216-5, ISO 21028 |

Global LNG Industry Trends and Tubing Requirements

The global LNG infrastructure expansion is driving demand for premium cryogenic tubing:

- Southeast Asia: LNG import terminals in Vietnam, Malaysia, and Indonesia prefer 316LN stainless tubes for cryogenic piping and process modules.

- Middle East: Major LNG exporters in Qatar and UAE are upgrading to nickel alloy tubing to improve system longevity in offshore zones.

- Europe and USA: Growth in LNG bunkering and cold-chain logistics leads to increased use of low-carbon stainless steel cryogenic tubes.

DLSS Engineering Insights on LNG Tubing

“Every cryogenic project we support starts with material selection. For general-purpose LNG storage, 304LN is solid. But in salt-laden environments or cyclic systems, 316LN or nickel alloys are far more reliable,”

— DLSS Technical Team

Frequently Asked Questions (FAQ)

Q1: Is standard 304 stainless steel suitable for LNG applications?

No. You should use 304L or 304LN stainless steel tubes for better low-temperature performance and impact toughness.

Q2: Why choose 316LN over 316L stainless steel for cryogenic tubes?

The added nitrogen in 316LN improves mechanical strength and cryogenic ductility, making it safer and more durable for LNG vaporizers and transfer lines.

Q3: Can duplex stainless steel be used in cryogenic pipelines?

Not always. Duplex grades must be carefully selected and tested to avoid ferrite phase-related cracking at low temperatures. Austenitic stainless steels remain the safer choice in most LNG systems.

Conclusion: Durable Stainless Steel Tubing for Extreme Cold

LNG and cryogenic systems require tubing that performs under extreme cold, pressure, and corrosion exposure. Whether you’re building vaporizers, low-temperature headers, or subsea transfer lines, DLSS offers certified cryogenic stainless steel tubing with full traceability and compliance.

We help clients in over 40 countries reduce risk, extend equipment life, and ensure safe delivery of energy in the most critical environments.