Meta Description:

Explore what electropolished (EP) stainless steel tubes are, how they are manufactured, and why they are essential for ultra-clean applications such as pharmaceuticals, biotechnology, and semiconductors.

Introduction

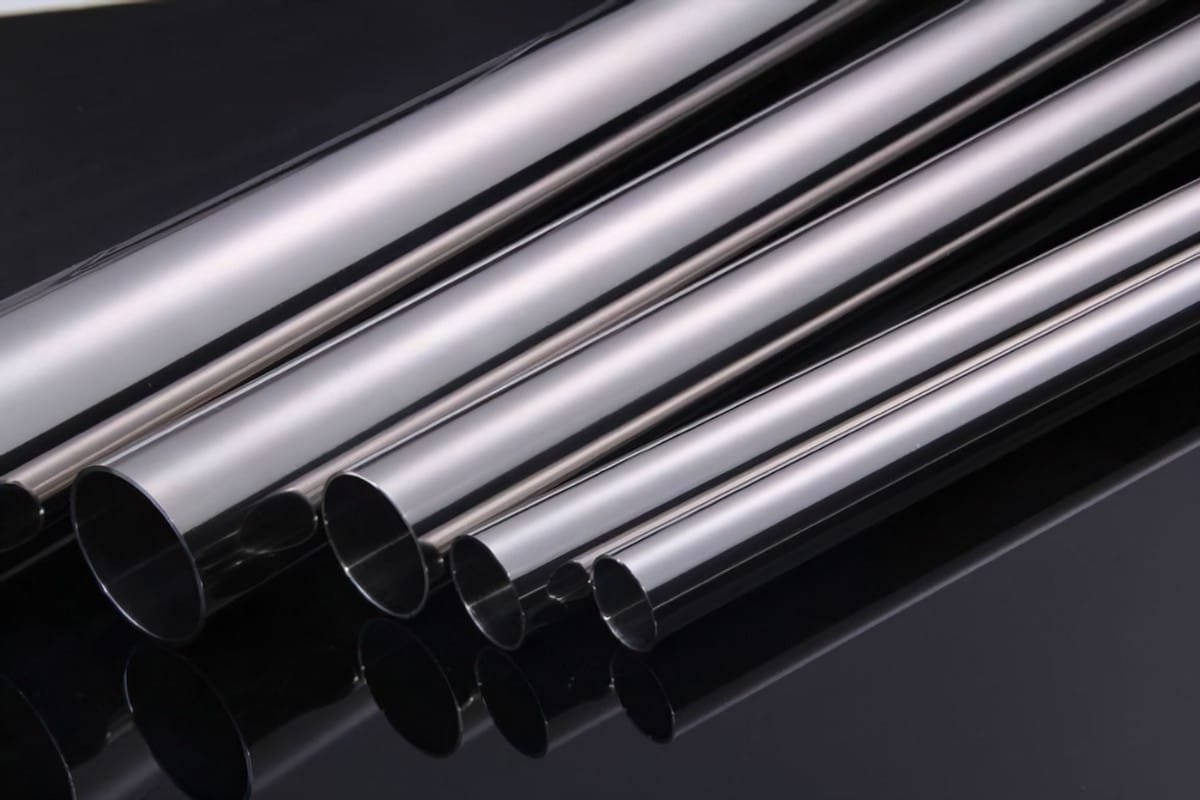

In ultra-clean environments like pharmaceutical plants, biotech labs, and semiconductor fabs, the surface of a stainless steel tube must be as smooth and contamination-free as possible. This is where Electropolished (EP) tubes come in.

Electropolishing enhances the cleanability, corrosion resistance, and microbial control of stainless steel tubes—making them the standard for GMP-compliant and FDA-grade systems.

1. What is Electropolishing?

Electropolishing is an electrochemical process that removes a thin layer of material from the metal surface, resulting in a microscopically smooth, bright, and passive finish.

Key Features:

- Ra (roughness average) can reach ≤ 0.25 µm or better

- Eliminates micro-crevices and burrs

- Enhances passivation and surface cleanliness

- Reduces particle adhesion and microbial growth

Read more at: ASTM B912 – Standard Specification for Passivation by Electropolishing

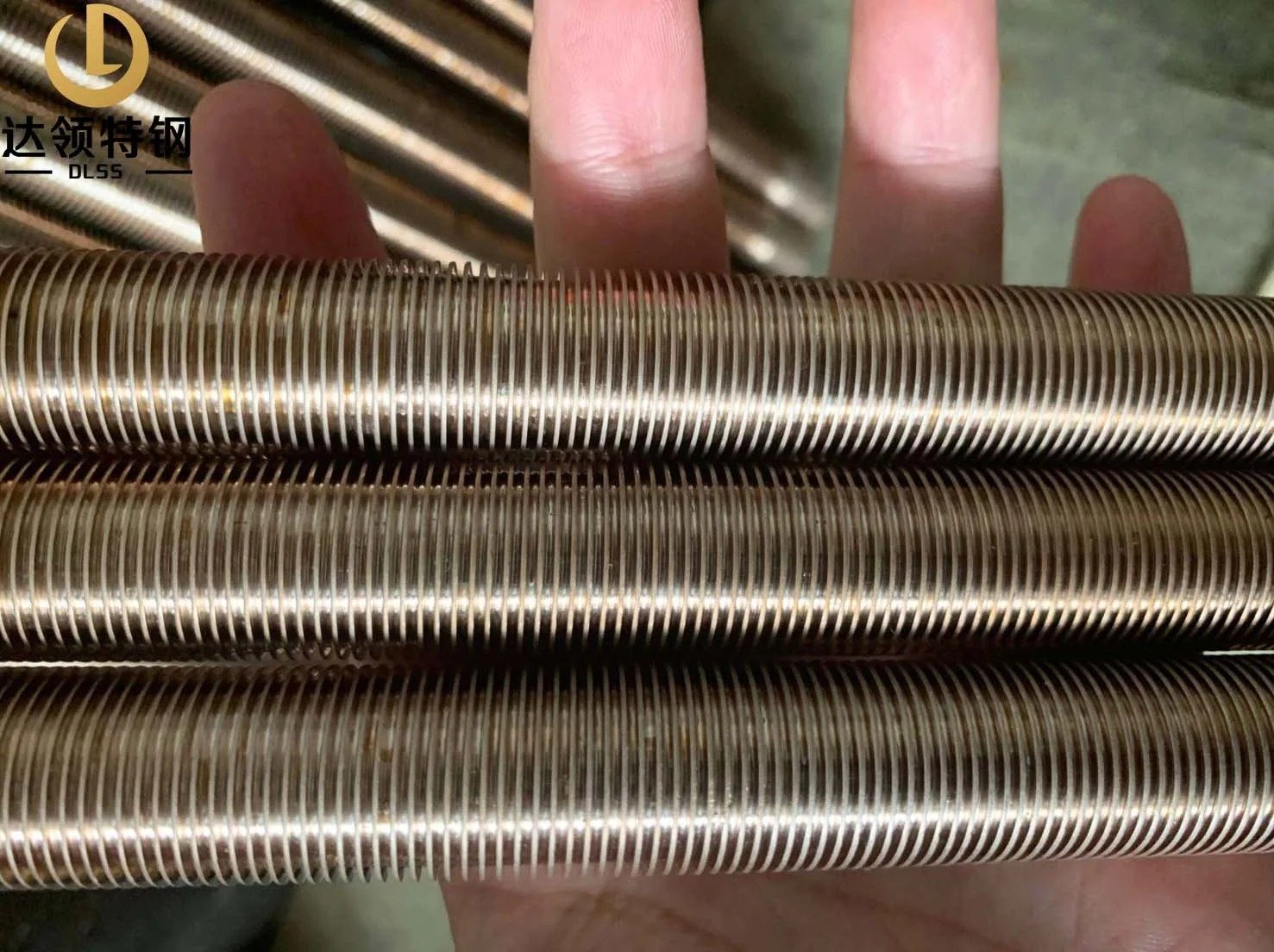

2. EP Tube Manufacturing Process at DLSS

DLSS provides EP tubes through a controlled process:

- Tube Selection:

Start with bright annealed (BA) seamless tubes made from TP316L, TP304L, or special alloys like TP316L UG, AL-6XN, or Hastelloy C-22. - Surface Preparation:

Tubes are degreased, rinsed, and inspected for surface defects. - Electropolishing:

Tubes are placed in an electrolyte bath, and a DC current is applied to dissolve surface high points. - Neutralization and Passivation:

Neutralize acid residue and create a uniform passive film using citric or nitric acid. - Final Testing:

Surface Ra inspection, visual inspection, borescope check, and optional SEM for high-purity projects.

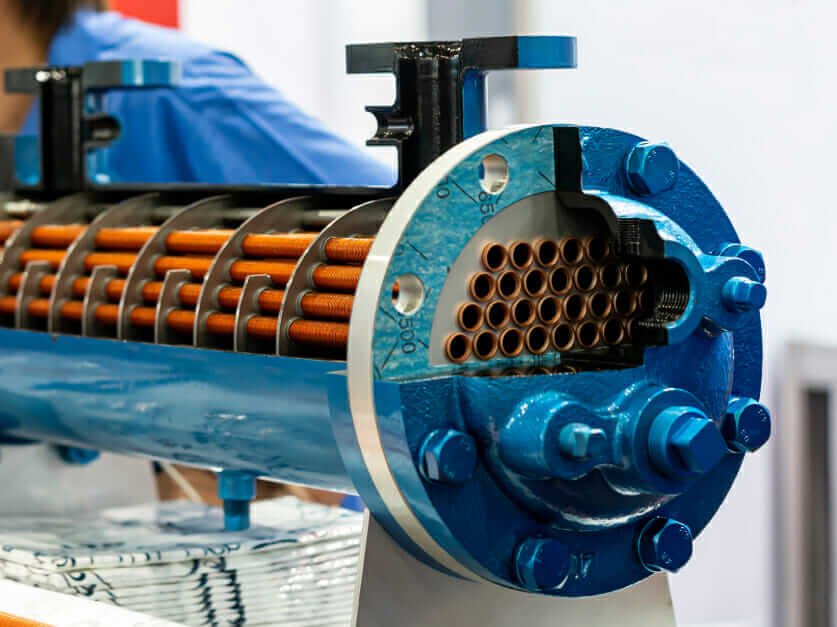

3. Comparison: EP vs Other Finishes

| Feature | Electropolished (EP) | Bright Annealed (BA) | Pickled |

|---|---|---|---|

| Surface Roughness (Ra) | ≤ 0.25 µm | ~0.2–0.5 µm | ≥ 0.5 µm |

| Cleanability | Excellent | Good | Moderate |

| Microbial Control | Excellent | Good | Low |

| GMP / FDA Compliance | Yes | Conditional | No |

| Appearance | Shiny, chrome-like | Bright silver | Dull white |

4. Applications of Electropolished Tubes

| Industry | Application Examples |

|---|---|

| Pharmaceutical | Water for Injection (WFI), purified water loops |

| Semiconductor | Ultra-pure gas delivery systems |

| Food & Beverage | CIP/SIP systems, sterile filling lines |

| Biotechnology | Bioreactors, fermentation piping |

| Medical Devices | Implant manufacturing, cleanroom utilities |

Related guide: ASME BPE Standard – Bioprocessing Equipment

5. DLSS EP Tube Capabilities

| Specification | Range / Value |

|---|---|

| Material Grades | TP316L, 304L, AL-6XN, Hastelloy C-22 |

| OD Range | 6 mm – 25.4 mm |

| Wall Thickness | 0.5 mm – 2 mm |

| Max Length | Up to 6,000 mm |

| Surface Roughness (Ra) | ≤ 0.25 µm |

| Inspection | Ra, borescope, PMI, chemical, IGC |

| Certification | EN 10204 3.1 / 3.2, ASTM B912, BPE |

DLSS also supports custom electropolishing for U-bent tubes, EP + passivation combo, and clean packaging with nitrogen purge.

FAQs

Q1: Is EP tubing mandatory for pharmaceutical applications?

Yes, in most GMP and FDA-regulated environments. EP ensures minimal bacterial adhesion and easy sterilization.

Q2: Can DLSS certify EP tubes per ASME BPE?

Yes. Upon request, we follow BPE guidelines and provide full documentation, Ra charts, and weld qualification if needed.

Q3: What packaging is used for EP tubes?

Each tube is individually packed in PE bag, end-capped, nitrogen-filled, and sealed in a clean environment.

Q4: How do you test EP quality?

DLSS tests each batch for surface roughness, performs borescope inspections, and supplies certificates and photos.

Conclusion

Electropolished tubes are essential for any system where cleanliness, corrosion resistance, and smooth internal surfaces are non-negotiable. DLSS delivers high-quality EP tubing with precision surface control, documentation, and compliance with global standards.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Looking for pharmaceutical-grade electropolished stainless steel tubes? DLSS supports full traceability, testing, and export logistics worldwide.