Southeast Asia is entering a new wave of industrial growth. Governments across the ASEAN region—including Thailand, Vietnam, Malaysia, and Indonesia—are investing billions in industrial parks, refineries, food processing plants, and energy facilities.

For global suppliers of heat exchanger tubes, U-bent coils, and industrial stainless steel piping, this presents an exciting opportunity—if you know where to look, and how to meet the new technical expectations.

1. Where Demand Is Coming From

The following are examples of high-growth industrial park clusters in the region:

| Country | Key Industrial Zones | Applications Requiring Tubes |

|---|---|---|

| Thailand | EEC (Eastern Economic Corridor), Map Ta Phut | Petrochemical plants, ammonia cooling systems |

| Malaysia | Johor & Sarawak Industrial Parks | Palm oil refineries, biomass energy systems |

| Indonesia | Batang Integrated Industrial Estate, Jababeka | Textile dyeing, chemical processing, LNG |

| Vietnam | VSIP Parks (e.g., Binh Duong) | Food processing, boiler systems, pharma HVAC |

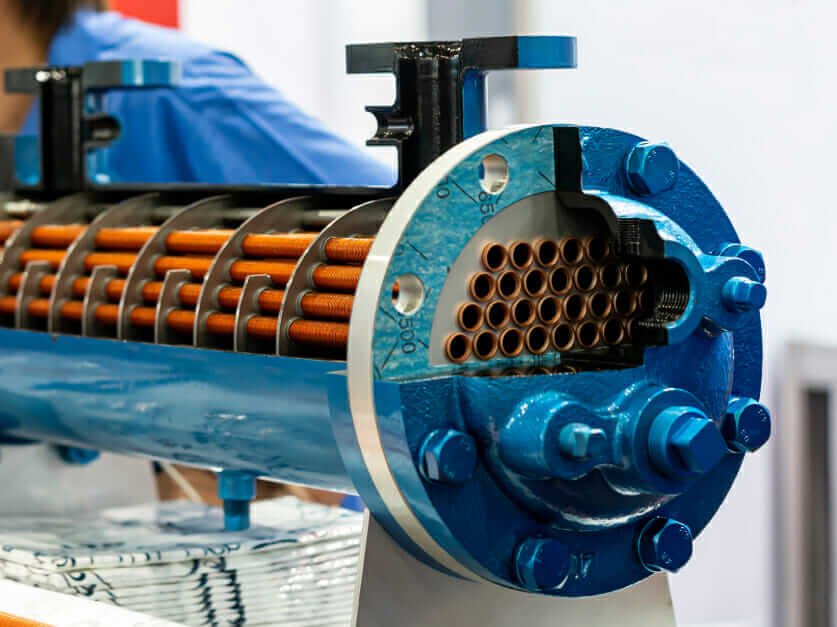

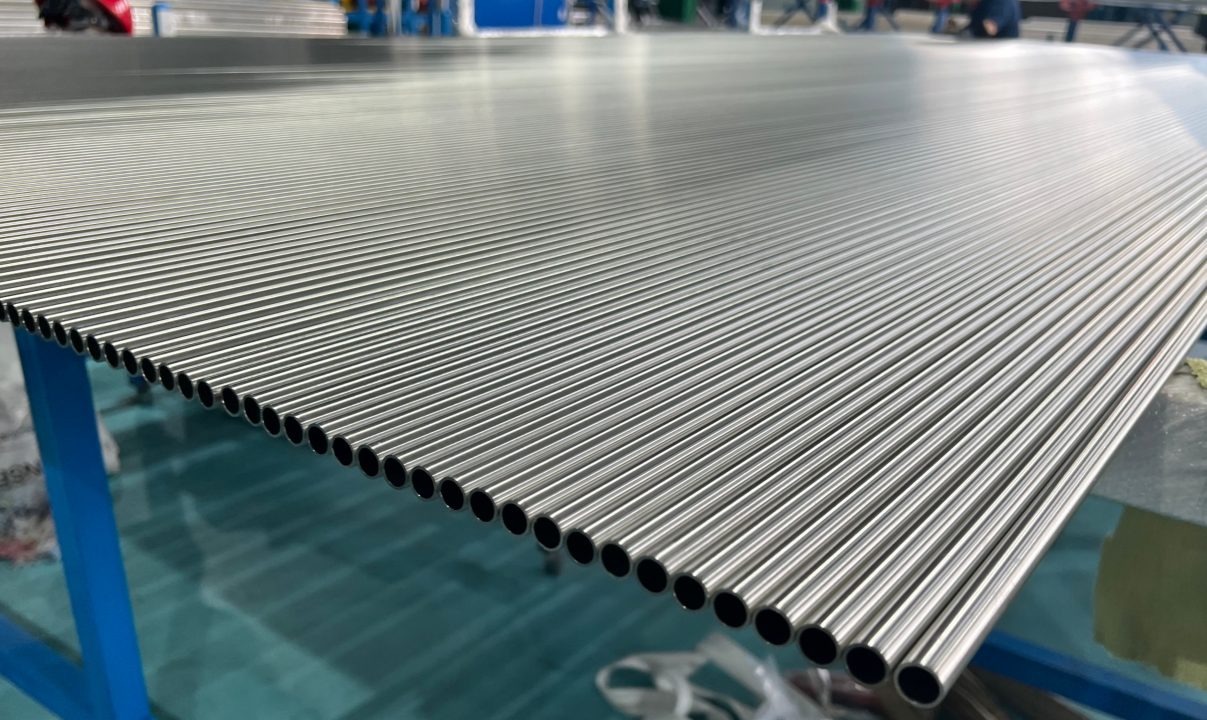

These projects often require ASME SA213, ASTM A249, or EN 10216-5 stainless steel tubes, tailored to heat transfer, corrosion resistance, and thermal cycling tolerance.

2. What Southeast Asian Buyers Now Expect

While cost remains a concern, technical capability and delivery assurance are becoming equally important.

| Buyer Expectation | Details |

|---|---|

| Standard compliance | ASME, PED, JIS G3463 depending on end-use |

| Documentation | 3.1 certificates, PMI reports, dimensional inspection logs |

| Clean inner surface | Especially for steam, chilled water, or food-grade systems |

| Custom lengths & bending | U-bent tubes, finned tubes, bundle design support |

| Delivery planning | Sea freight + inland trucking coordination for remote sites |

Many EPC contractors and buyers in Thailand, Malaysia, or Vietnam now expect at least a partial understanding of local regulations and industry terms.

3. Local Procurement Patterns: What You Must Know

- Local agents or importers often handle customs clearance—ensure HS code accuracy and consignment-ready packaging

- Palm oil and biomass projects require corrosion-resistant tubes (e.g., TP316L or 2205) for heat recovery units

- Food and beverage processors increasingly demand sanitary tubes with smooth finish and no pickling residue

- Government-backed projects may involve international bidding and pre-qualification documentation

Example: Malaysia’s palm oil processors require bright-annealed or pickled TP304/316 tubes, with low carbon content and tested for intergranular corrosion.

4. How Global Tube Suppliers Can Win

| Strategy | Advantage |

|---|---|

| Quick quotation turnaround (≤24h) | Many ASEAN buyers are speed-focused |

| Flexible MOQ and sample support | Especially for trial projects or plant upgrades |

| Reference projects in similar sectors | Helps build credibility |

| Support for TPI inspections | TÜV, SGS, BV inspections often requested |

| Multilingual or local partner communication | English + Bahasa/Thai/Vietnamese enhances trust |

Frequently Asked Questions (FAQ)

Q1: Which tube standards are commonly used in ASEAN EPC projects?

A: ASME SA213/SA249, ASTM A269, EN10216-5, and sometimes JIS G3463. U-tubes often follow TEMA standards for heat exchanger bundles.

Q2: Are sanitary-grade tubes in demand in Southeast Asia?

A: Yes. Especially in Vietnam, Thailand, and the Philippines, where food & beverage and pharma sectors are expanding. Tubes must meet surface finish and material traceability standards.

Q3: How important is the inner surface finish for heat exchanger tubes?

A: Very. Clean and smooth surfaces improve thermal efficiency, reduce fouling, and are often mandatory in steam or chemical systems.

Q4: Can Chinese suppliers compete with local ASEAN tube manufacturers?

A: Yes—especially in large-volume, high-specification, or certified orders where quality and documentation are critical. Logistics and local support are key differentiators.

Conclusion: From Pipe to Partnership

The rise of Southeast Asia’s industrial parks is not just about physical infrastructure—it’s about building networks of trust, technical reliability, and speed.

Suppliers who offer not just tubes, but tailored engineering support, document compliance, and project references will secure long-term business from ASEAN buyers.

If you’re ready to go beyond selling steel—and start building regional partnerships—now is the time.