Meta Description:

Explore how stainless steel seamless tubes support South America’s oil, gas, and petrochemical infrastructure. Learn about key materials, standards, and corrosion-resistant solutions for high-performance applications.

Introduction

South America is rich in natural resources—but also in engineering challenges. With vast offshore oil fields, mountainous LNG projects, and acidic mining processes, the region demands durable, corrosion-resistant piping systems.

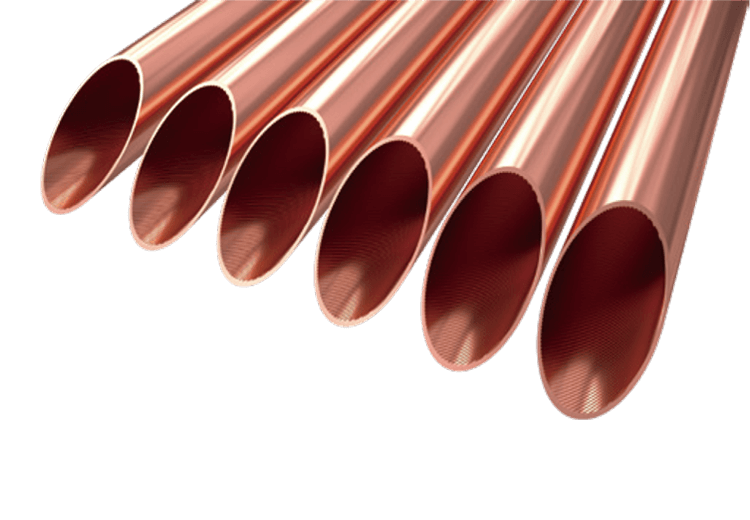

Stainless steel seamless tubes have become the material of choice across the continent for reliability, strength, and long lifecycle performance. From Brazil’s offshore rigs to Chile’s lithium refineries, let’s explore why.

South America’s Industrial Demands Require Premium Tubing

The region’s industries operate in high-risk, high-salinity, and chemically aggressive environments.

Key industries using stainless steel tubes include:

| Industry | Country | Common Application |

|---|---|---|

| Oil & Gas | Brazil, Colombia | Offshore platforms, sour gas pipelines |

| Mining | Chile, Peru | Acid leaching, solvent extraction heat exchangers |

| Petrochemical | Argentina | Ammonia plants, reformers, cooling systems |

| Desalination | Chile, Peru | SWRO pre-heaters, brine cooling systems |

| Food Processing | Brazil, Ecuador | Sanitary piping, steam condensers |

These sectors demand seamless tubes that can resist corrosion, temperature fluctuation, and pressure cycles.

Recommended Stainless Steel Grades for South America

Based on local water chemistry (chlorides, sulfates), temperature, and media, the following grades perform well:

| Grade | Properties / Standards | Typical Use |

|---|---|---|

| 316L | High chloride resistance / ASTM A213, A269 | Offshore and seawater systems |

| 317L | Superior pitting resistance / ASTM A213 | High-chloride mining and chemical processes |

| 904L | High corrosion + sulfuric acid tolerance / ASTM B677 | Lithium extraction and fertilizer plants |

| Duplex 2205 | High strength + crack resistance / ASTM A789 | Pressure piping in offshore rigs |

| 304/304L | Cost-effective / For clean-water or food-grade services | Food, beverage, light industry |

Why Seamless Tubes Over Welded in Latin America?

- Better corrosion resistance in high-salinity coastal environments

- Higher pressure rating—ideal for mountainous regions with fluctuating altitude pressures

- Fewer failure points under mechanical stress or chemical attack

- More accepted under NACE MR0175 / ISO 15156, often required in Petrobras and YPF tenders

Explore ASTM A213 & A269 standards

DLSS Tube Specifications for South America Projects

DLSS offers custom tube supply based on Latin American needs:

- OD range: 6.35 mm to 114.3 mm

- Wall thickness: 0.7 mm to 8 mm

- Lengths: Up to 12 meters (custom cut-to-length)

- Surface finish: Pickled, BA (Bright Annealed), Polished, Electropolished

- Testing: UT, ET, Hydrostatic, PMI, Grain size, NACE compliance

- Certifications: EN10204 3.1, 3.2 by BV, TUV, DNV upon request

South America Case Highlight

Client: Offshore FPSO in Brazil

Solution: TP316L seamless tubes, BA surface, ASTM A213 + NACE MR0175

Use: Cooling and instrumentation lines exposed to seawater spray

Result: 0% corrosion after 18 months of service, outperforming previous welded solution

FAQs

Q1: Are your tubes suitable for sour gas environments like in Colombia or Argentina?

Yes. We supply NACE MR0175-compliant tubing in 316L, Duplex, and Incoloy alloys.

Q2: Can you deliver to South American ports?

Yes. We frequently ship to Santos (Brazil), Callao (Peru), Cartagena (Colombia), Valparaíso (Chile).

Q3: How do you ensure product traceability?

We provide full mill test certificates, batch numbers, and optional 3rd-party inspection reports.

Conclusion

South America’s infrastructure is evolving rapidly—and DLSS’s stainless steel seamless tubes offer a proven, compliant, and durable solution to support that growth. Whether for offshore platforms, mining heat exchangers, or chemical plants, we’re ready to deliver precision and performance.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Looking to source stainless steel tubes for South American industrial projects? Let’s discuss your application and deliver a tailored solution.