Meta Description:

Explore rare and exotic alloy tubes like Incoloy 825, 254 SMO, Monel 400, and more. These metals offer unmatched corrosion and temperature resistance for specialized industries.

Introduction

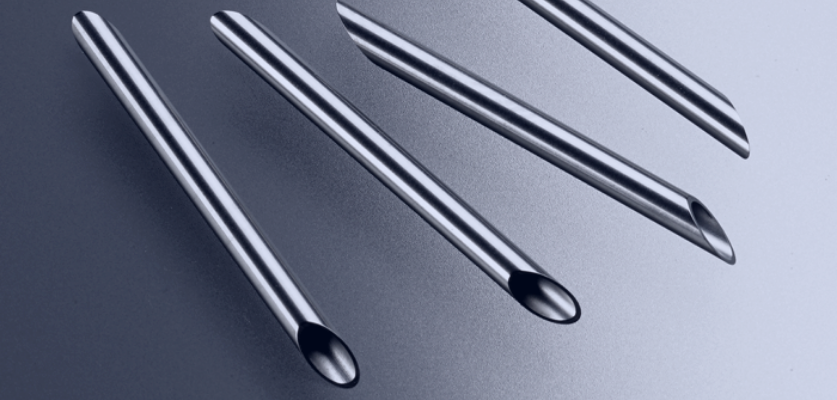

While 304 and 316 stainless steels dominate industrial applications, many extreme environments require specialty or rare metal alloys for superior corrosion resistance, strength, or temperature tolerance.

This article highlights five lesser-known yet powerful materials used to produce seamless or welded tubes, especially in demanding sectors such as chemical processing, nuclear energy, and marine systems.

1. Incoloy® 825 (UNS N08825)

- Standard: ASTM B163 / B423

- Type: Nickel-iron-chromium alloy

- Typical Use: Chemical reactors, sulfuric acid pickling lines, offshore oil platforms

Incoloy 825 provides outstanding resistance to sulfuric and phosphoric acid, making it ideal for aggressive chemical environments. It also withstands chloride-induced stress corrosion cracking, common in seawater service.

Refer to Special Metals Incoloy 825 Datasheet for detailed specs.

2. 254 SMO (UNS S31254)

- Standard: ASTM A269 / A312

- Type: Super-austenitic stainless steel

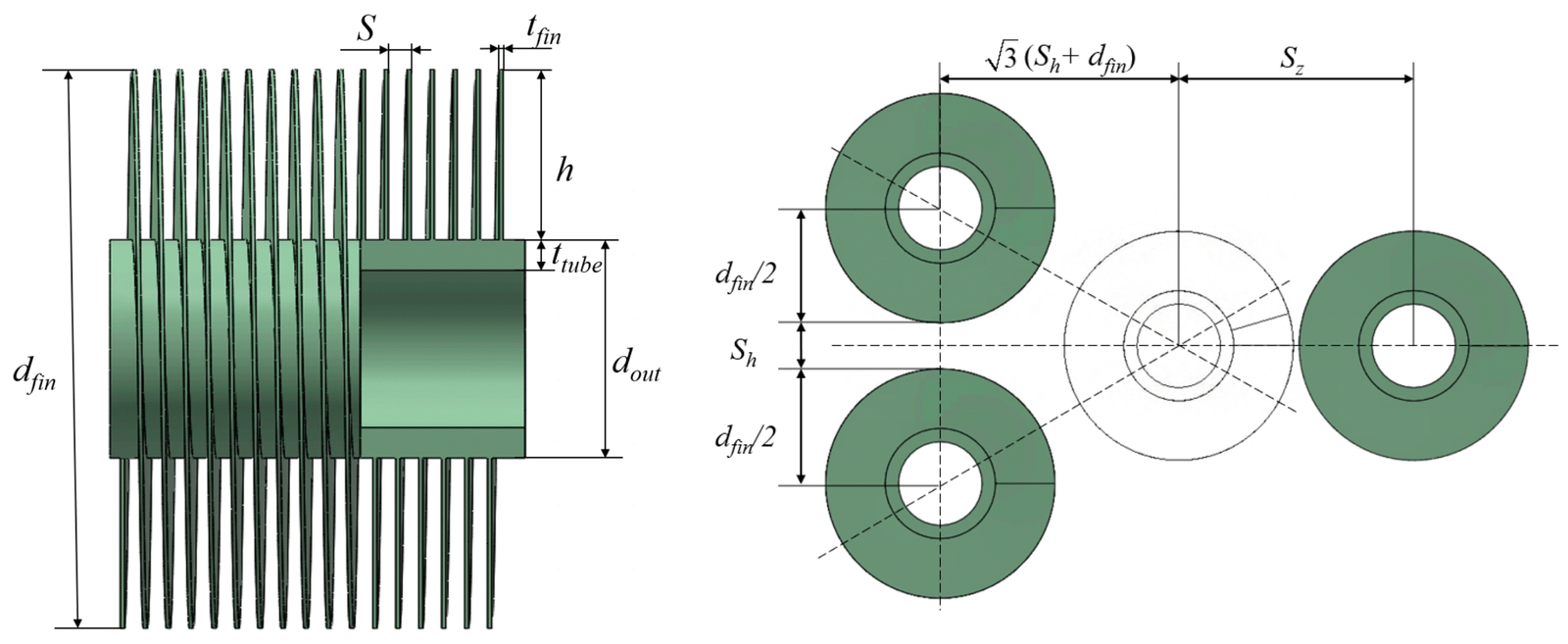

- Typical Use: Seawater heat exchangers, pulp bleaching plants, desalination

With pitting resistance equivalent number (PREN) > 42, 254 SMO is far more corrosion-resistant than 316L, especially in high-chloride or brine environments. Its mechanical strength is also 1.5× higher than austenitic grades.

See Outokumpu’s 254 SMO brochure for more.

3. Monel® 400 (UNS N04400)

- Standard: ASTM B165

- Type: Nickel-copper alloy

- Typical Use: Alkali production, marine piping, deaerating heaters

Monel 400 offers excellent resistance to caustic alkalies, saltwater, and hydrofluoric acid. Unlike stainless steel, it doesn’t suffer from chloride stress corrosion. Its ductility and impact strength remain high even at sub-zero temperatures.

Detailed technical sheet: Haynes Monel 400

4. Hastelloy® C-22 (UNS N06022)

- Standard: ASTM B622 / B619

- Type: Nickel-chromium-molybdenum alloy

- Typical Use: Waste incineration, flue gas scrubbers, chemical reactors

C-22 is one of the most versatile corrosion-resistant alloys, outperforming even Hastelloy C-276 in many acidic environments. It resists oxidizing and reducing agents simultaneously.

5. Titanium Grade 2 (UNS R50400)

- Standard: ASTM B338 / B861

- Type: Commercially pure titanium

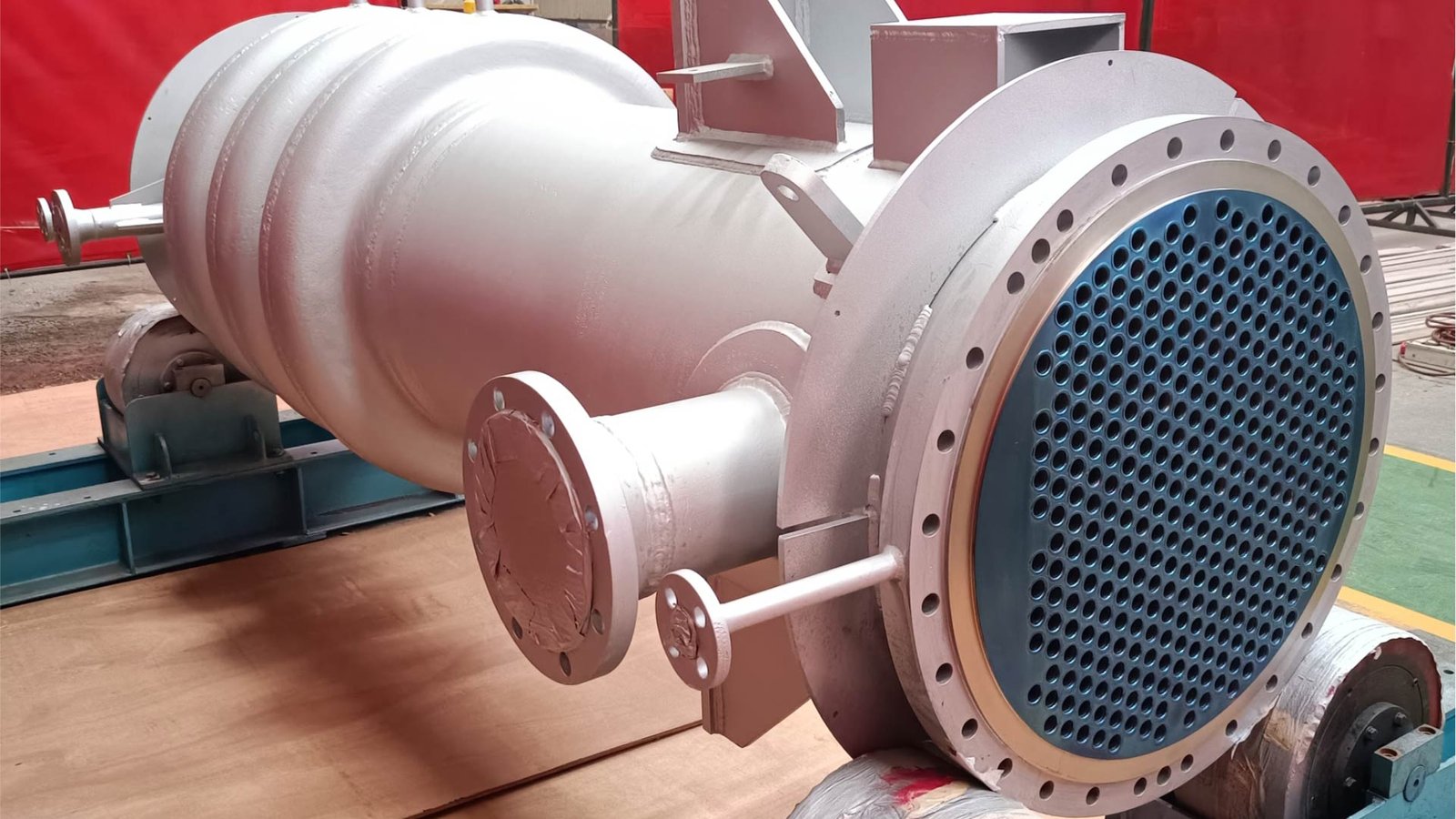

- Typical Use: Heat exchangers in desalination, chlor-alkali plants, power plants

Titanium Grade 2 offers exceptional resistance to seawater corrosion, biofouling, and erosion. It’s ideal for applications requiring long service life without corrosion-induced failures. Despite being light, it’s incredibly strong and durable.

Find more at Titanium Industries Inc.

Why Use Rare Alloy Tubes?

These materials may cost more than standard stainless steel, but their performance in aggressive chemical, high-temperature, or offshore environments prevents costly system failures, unplanned shutdowns, or corrosion damage.

When project specs mention NACE MR0175 compliance, chloride resistance, or oxidation stability, one of these materials is often the best-fit choice.

DLSS Capabilities

DLSS provides seamless and welded tubes in:

- Incoloy 825

- 254 SMO

- Monel 400

- Hastelloy C-22

- Titanium Gr.2

- CuNi alloys (C70600 / C71500)

- Super Duplex (S32750 / S32760)

Our tubes meet international standards (ASTM, EN, ASME) and can be delivered with:

- EN 10204 3.1 / 3.2 Certificates

- PMI, NDT, and corrosion test reports

- Custom lengths, U-bends, surface finish options

Conclusion

In harsh environments, material selection isn’t optional—it’s critical. By exploring less common alloys like Incoloy, Monel, or 254 SMO, engineers can design systems that last longer, require less maintenance, and perform better.

Let DLSS help you source rare alloy tubes with certified quality and expert support.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need help choosing the right alloy tube for your project? Our technical team is ready to assist.