Meta Description:

Explore the differences between duplex and super duplex stainless steel tubes. Learn about their chemical composition, corrosion resistance, mechanical strength, and best-use applications in harsh environments.

Introduction

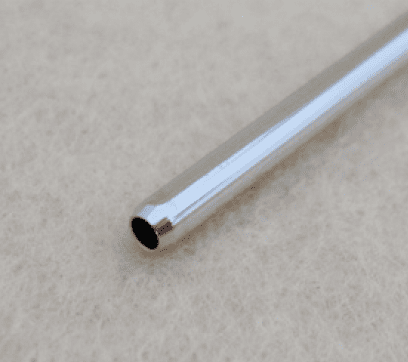

When stainless steel isn’t enough for aggressive environments—duplex and super duplex stainless steels step in. These high-performance materials combine the advantages of both austenitic and ferritic structures, offering exceptional strength and corrosion resistance, particularly in chloride-rich and offshore settings.

At DLSS, we supply duplex and super duplex seamless tubes to industries demanding extreme performance and compliance with ASTM, EN, and NORSOK standards.

1. What Are Duplex and Super Duplex Stainless Steels?

- Duplex stainless steel has a two-phase microstructure: ~50% austenite and ~50% ferrite.

- Super duplex stainless steel has higher chromium (Cr), molybdenum (Mo), and nitrogen (N) content for superior corrosion resistance and strength.

| Property | Duplex 2205 (UNS S32205) | Super Duplex 2507 (UNS S32750) |

|---|---|---|

| Chromium (%) | 22 | 25 |

| Molybdenum (%) | 3.1 | 4.0 |

| PREN (Pitting Resistance) | ~35 | >40 |

| Yield Strength (MPa) | ≥450 | ≥550 |

| Max Service Temperature | 300°C | 250°C |

Learn more at: Outokumpu Duplex Handbook

2. Key Benefits of Duplex and Super Duplex Tubes

- High Corrosion Resistance

Especially effective against chloride-induced pitting, crevice corrosion, and stress corrosion cracking. - Excellent Strength

Twice the yield strength of 304/316 austenitic grades—ideal for high-pressure and structural applications. - Good Weldability

Can be welded using standard techniques with proper precautions (e.g., heat input control). - Cost Efficiency

Due to high strength, wall thickness can be reduced, leading to material and weight savings.

3. Common Duplex & Super Duplex Grades Supplied by DLSS

| Grade | UNS Number | Standard | Applications |

|---|---|---|---|

| Duplex 2205 | S32205 | ASTM A789 / A790 | Offshore piping, heat exchangers |

| Super Duplex 2507 | S32750 | ASTM A789 / A790 | Desalination, chemical tank systems |

| S31803 | S31803 | ASTM A789 / EN 10216-5 | Structural components |

| Zeron 100 | S32760 | NORSOK, ASTM A928 | Subsea oil & gas systems |

All DLSS tubes can be delivered with 3.2 certifications, NDT (UT/ET), PMI reports, and corrosion testing as per NACE MR0175 / ISO 15156.

4. Applications of Duplex Tubes

| Industry | Application Examples |

|---|---|

| Oil & Gas | Offshore risers, downhole tubes, manifolds |

| Desalination Plants | Seawater heat exchangers, brine lines |

| Chemical Processing | Aggressive acid and salt transport |

| Pulp & Paper | Bleaching plant systems |

| Marine & Shipbuilding | Ballast water systems, structural tubing |

For industry-specific guidelines, refer to: NACE MR0175 Overview

5. How DLSS Ensures Quality

- Strict Alloy Control – Verified with 100% PMI using XRF/OES

- Heat Treatment – Solution annealed and water quenched

- Testing – Includes flattening, flaring, IGC, hardness, and hydro

- Documentation – Full traceability, 3.1 / 3.2 MTC, third-party witness (BV, SGS)

DLSS also offers customized U-bend, low-fin, and corrugated duplex tubes for specialized heat exchanger designs.

FAQs

Q1: Can duplex tubes be used in sour gas environments?

Yes, if they meet hardness and metallurgical requirements of NACE MR0175. DLSS offers certified tubes for sour service.

Q2: Are duplex tubes magnetic?

Partially. Due to the ferritic phase, duplex stainless steels exhibit mild magnetism, unlike fully austenitic grades.

Q3: How do duplex tubes compare to 316L in corrosion resistance?

Duplex 2205 is significantly more resistant to pitting and crevice corrosion, with higher PREN and strength.

Q4: What is the delivery time for super duplex tubes?

Standard sizes are typically shipped within 3–4 weeks. Custom sizes or witness testing may extend lead time slightly.

Conclusion

Duplex and super duplex stainless steel tubes offer a premium solution for challenging applications. Whether it’s offshore platforms or seawater systems, DLSS delivers robust, tested, and certified duplex tubing to meet global demands.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need duplex or super duplex tubing for your next high-stress project? DLSS provides full technical support, inspection-ready documentation, and global logistics coverage.