On October 1, 2023, the European Union launched its Carbon Border Adjustment Mechanism (CBAM) — a groundbreaking policy that requires importers to report the embedded carbon emissions of certain goods, including iron, steel, and stainless steel.

For stainless steel pipe and heat exchanger tube exporters, this marks a new era. Quality and price are no longer enough—carbon transparency and sustainable manufacturing practices are now critical factors in accessing and retaining customers in the European market.

1. What is CBAM?

CBAM is essentially a carbon tariff. It ensures that imported goods are subject to the same carbon costs as goods produced within the EU, under its Emissions Trading System (ETS).

From 2026 onward, non-compliant products may face actual carbon fees, and suppliers who cannot provide verified emissions data may be excluded from tenders or penalized.

Learn more from the European Commission’s CBAM Portal

2. Which Products Are Affected?

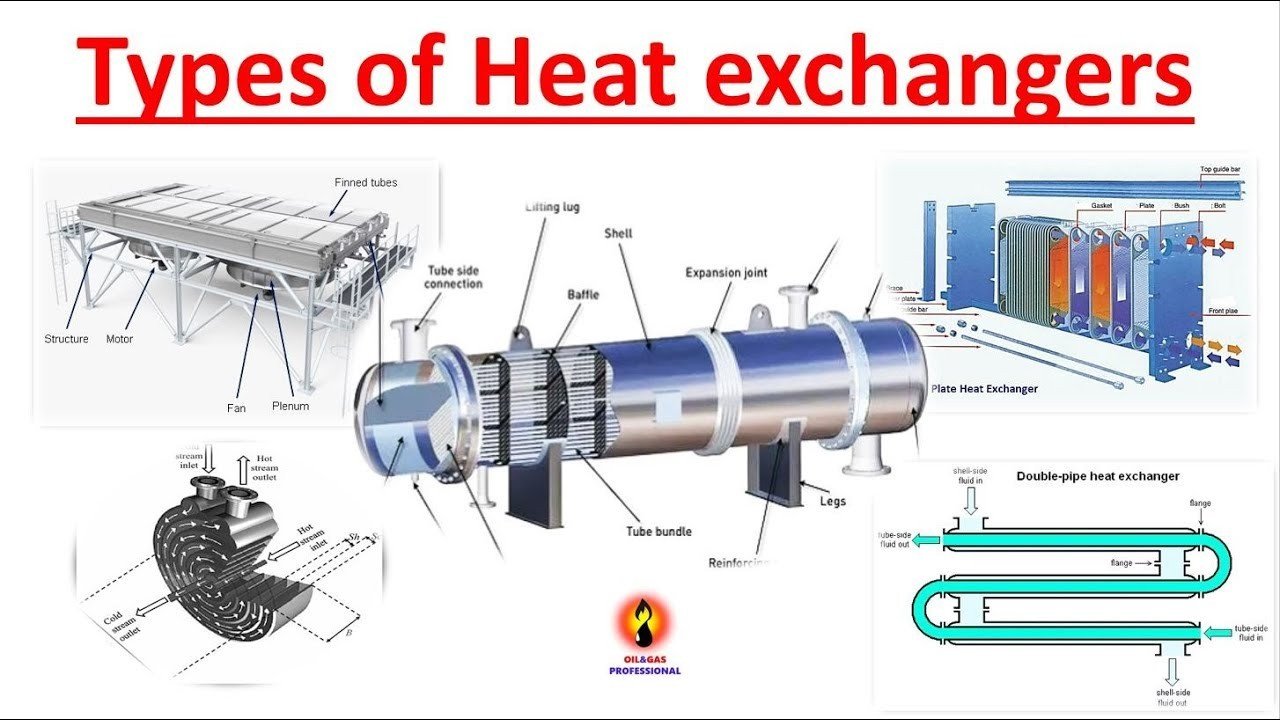

In the stainless steel industry, the following are currently covered under CBAM:

- Seamless stainless steel pipes and tubes (HS code 730441, 730449)

- Welded pipes and hollow sections

- Stainless steel ingots, billets, and slabs (raw materials)

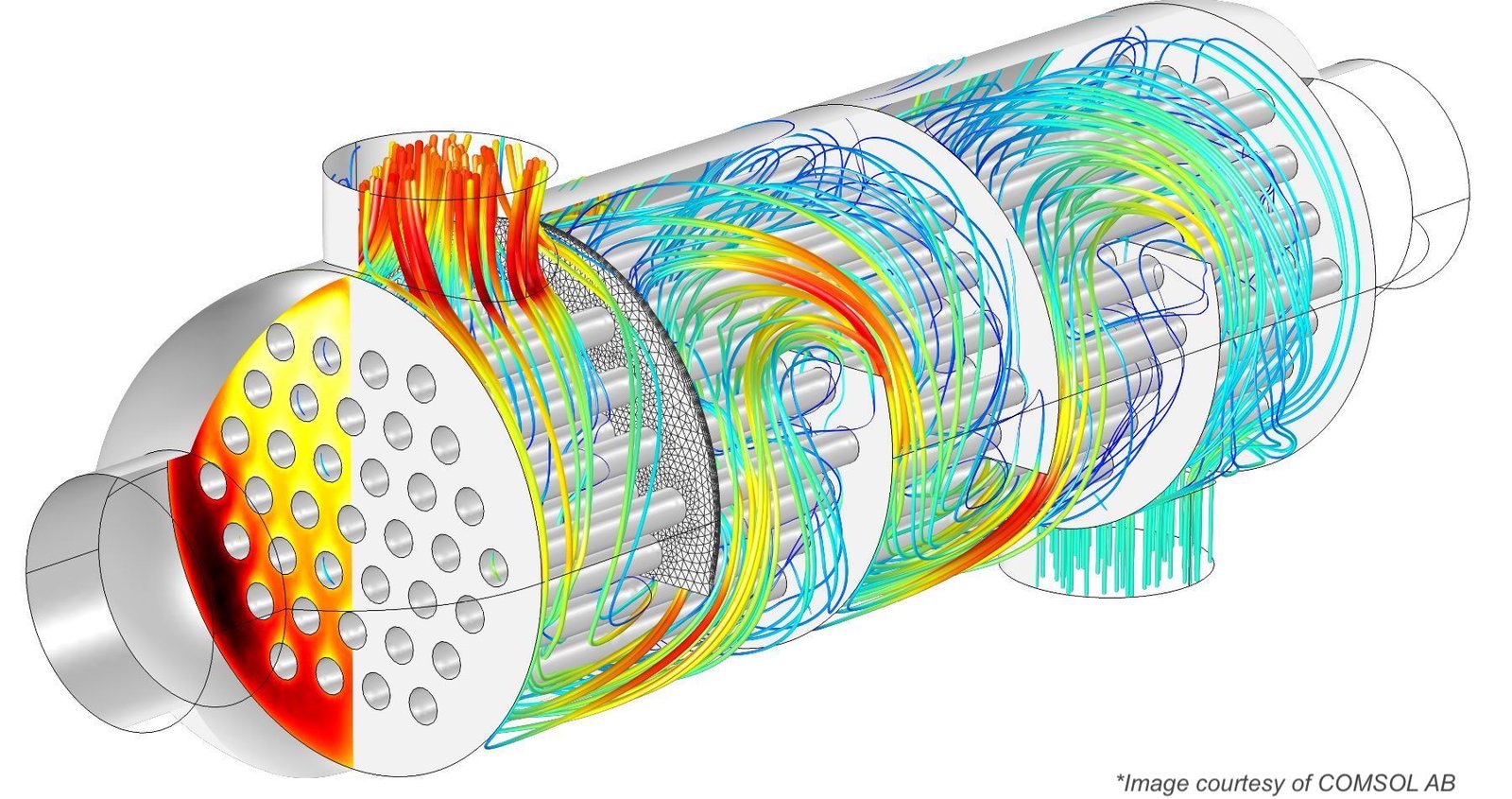

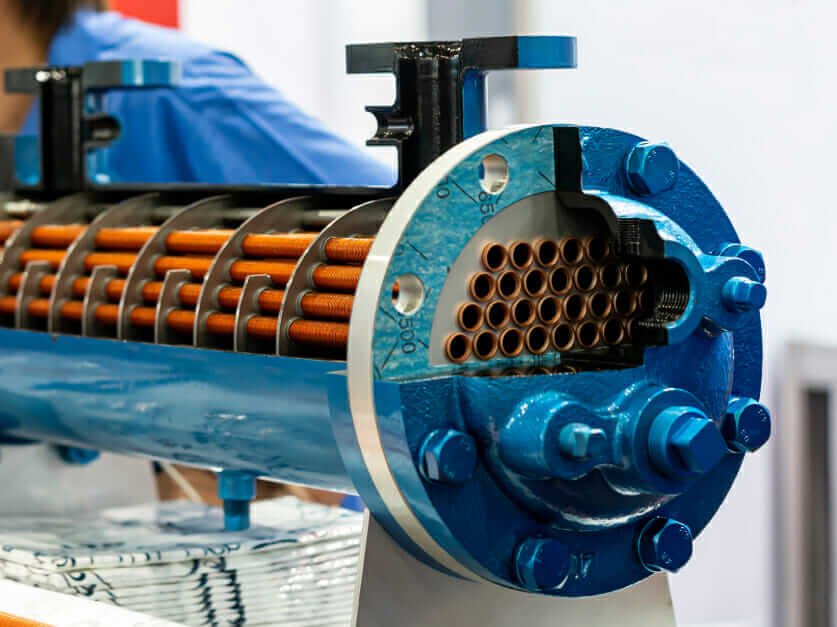

- Heat exchanger tube coils and assemblies

Exporters must now submit emissions reports for these products, including:

- Direct emissions from production

- Indirect emissions (from purchased electricity)

- Carbon footprint per ton, calculated under standards like ISO 14067

3. What Buyers in the EU Now Expect

Procurement teams, especially in industries like pharmaceuticals, energy, food processing, and construction, are under pressure to “green” their supply chains. That means:

| Requirement | Why It Matters |

|---|---|

| Low-carbon sourcing | Helps buyers reduce Scope 3 emissions and meet ESG goals |

| Emission disclosure | Required for CBAM compliance from 2026 onward |

| Green certifications | ISO 14001 (EMS), ISO 14067 (carbon footprint) |

| Sustainable packaging | Recyclable, marked, and documented for carbon tracking |

| Traceable production process | From melting to pickling—every step matters |

4. What Exporters Must Do to Stay Competitive

To succeed in the EU under CBAM, stainless steel tube manufacturers must go beyond product specs. Consider implementing:

- Product Carbon Footprint (PCF) system, based on GHG Protocol or ISO 14067

- Factory-wide carbon audits, possibly supported by third-party consultants

- Green labeling & QR traceability for each tube or bundle

- Digital documentation including energy source breakdown, mill test certificates, and emissions declarations

- Supply chain alignment, ensuring your upstream alloy suppliers also disclose carbon impact

Even small to mid-size buyers in Germany, Italy, or the Netherlands may now ask for emissions declarations alongside your EN 10204 3.1 certificate.

Frequently Asked Questions (FAQ)

Q1: Is CBAM already charging importers carbon taxes?

A: Not yet. The reporting phase is ongoing (2023–2025), but from January 2026, actual financial adjustments (carbon fees) will apply.

Q2: What happens if I can’t provide emission data for my stainless steel tubes?

A: Your customer may either reject the shipment, declare a high “default value” (resulting in a higher carbon fee), or stop working with your company.

Q3: How can I calculate the carbon footprint of my pipes?

A: You can follow the ISO 14067 standard or use third-party software and auditors specialized in PCF reporting. Your energy source (coal, hydro, solar) and production process steps (e.g., annealing, pickling) all impact the footprint.

Q4: What certifications help boost buyer confidence in Europe?

A: ISO 14001 (Environmental Management), ISO 9001, and a verified PCF report. ASME or PED remains necessary for product compliance, but green certifications are gaining weight.

Conclusion: Carbon Transparency Is Now a Competitive Advantage

CBAM is not just an environmental regulation—it’s a business filter. EU customers are becoming more selective, carbon-conscious, and documentation-heavy in their procurement.

Suppliers who embrace this shift by offering certified low-carbon stainless steel products, traceable manufacturing, and clear carbon reporting will become preferred long-term partners in the region.

If you’re still focusing only on price and delivery time—2025 might be your last warning. The new frontier is green compliance + high performance.