Introduction

Inconel 625 seamless tubes are high-performance nickel-chromium-molybdenum-niobium alloys known for their extraordinary strength, thermal stability, and corrosion resistance. These tubes are widely used in marine environments, offshore oil & gas platforms, nuclear systems, and chemical process plants, especially where chloride-induced pitting, stress corrosion cracking, or elevated temperatures are major concerns.

See: Inconel – Wikipedia

What Is Inconel 625?

Inconel 625 (UNS N06625) is a solid solution strengthened alloy that contains:

- Nickel (≥58%) – corrosion and oxidation resistance

- Chromium (~21%) – enhances resistance to oxidizing agents

- Molybdenum and Niobium – strengthen the alloy and improve resistance to pitting and crevice corrosion

This unique combination of elements makes Inconel 625 one of the most trusted materials in aggressive industrial environments.

Key Features of Inconel 625 Seamless Tubes

- Excellent resistance to chloride-induced stress corrosion cracking

- High strength without heat treatment due to niobium-based solid solution

- Excellent weldability with minimal risk of cracking

- Resistance to pitting, crevice corrosion, and oxidation

- Stable performance up to 980°C (1800°F)

- Non-magnetic, suitable for marine and defense applications

Keyword targets: Inconel 625 tube, UNS N06625 seamless pipe, high-temperature nickel alloy tube, chloride-resistant tubing

Mechanical Properties

| Property | Typical Value (Annealed) |

|---|---|

| Tensile Strength | ≥ 827 MPa |

| Yield Strength | ≥ 414 MPa |

| Elongation | ≥ 30% |

| Operating Temp. Range | -196°C to 980°C |

Reference standard: ASTM B444 – Inconel 625 Tubing

Applications of Inconel 625 Tubes

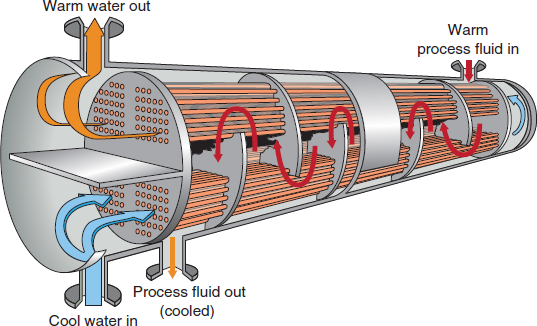

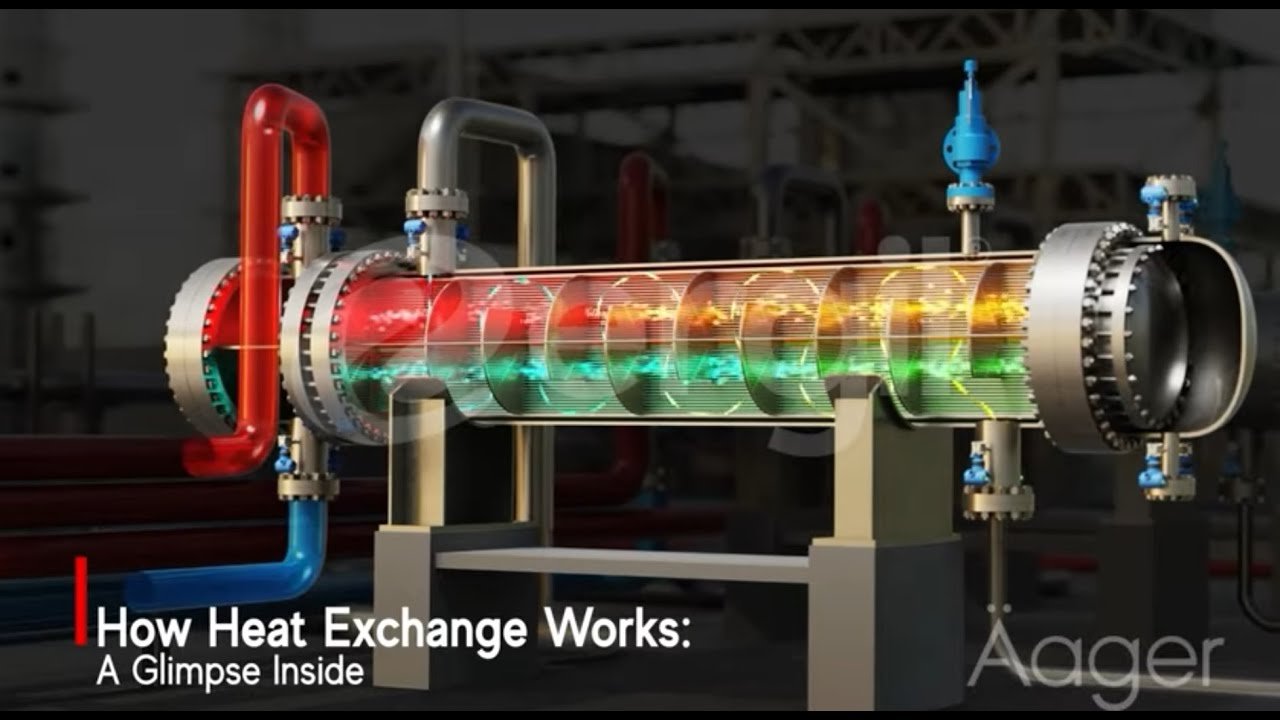

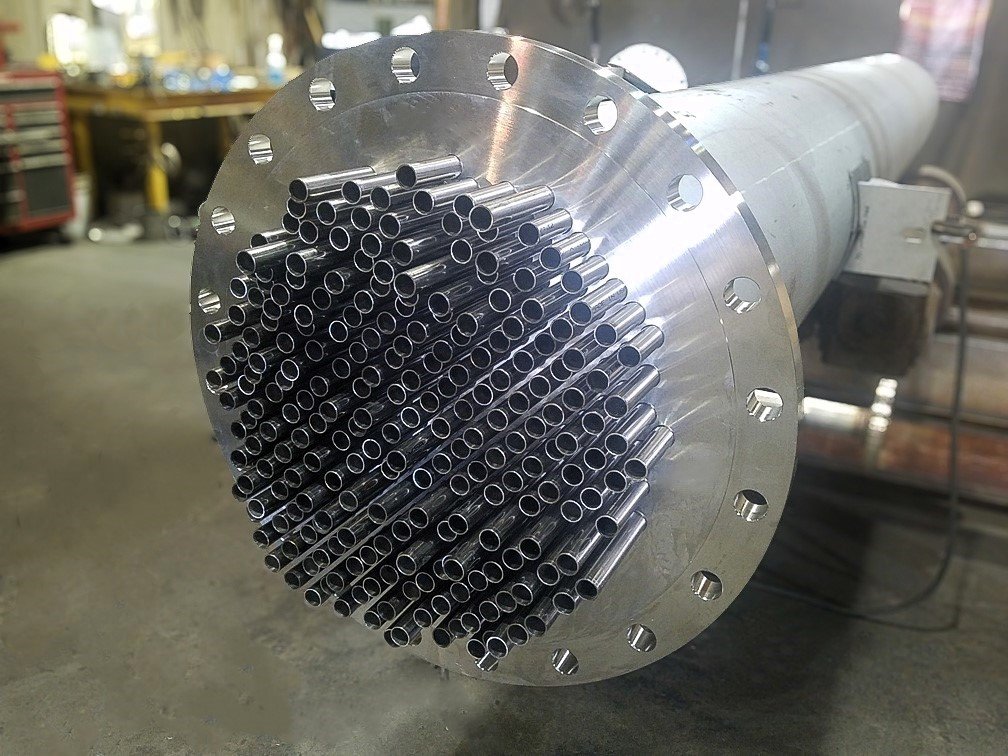

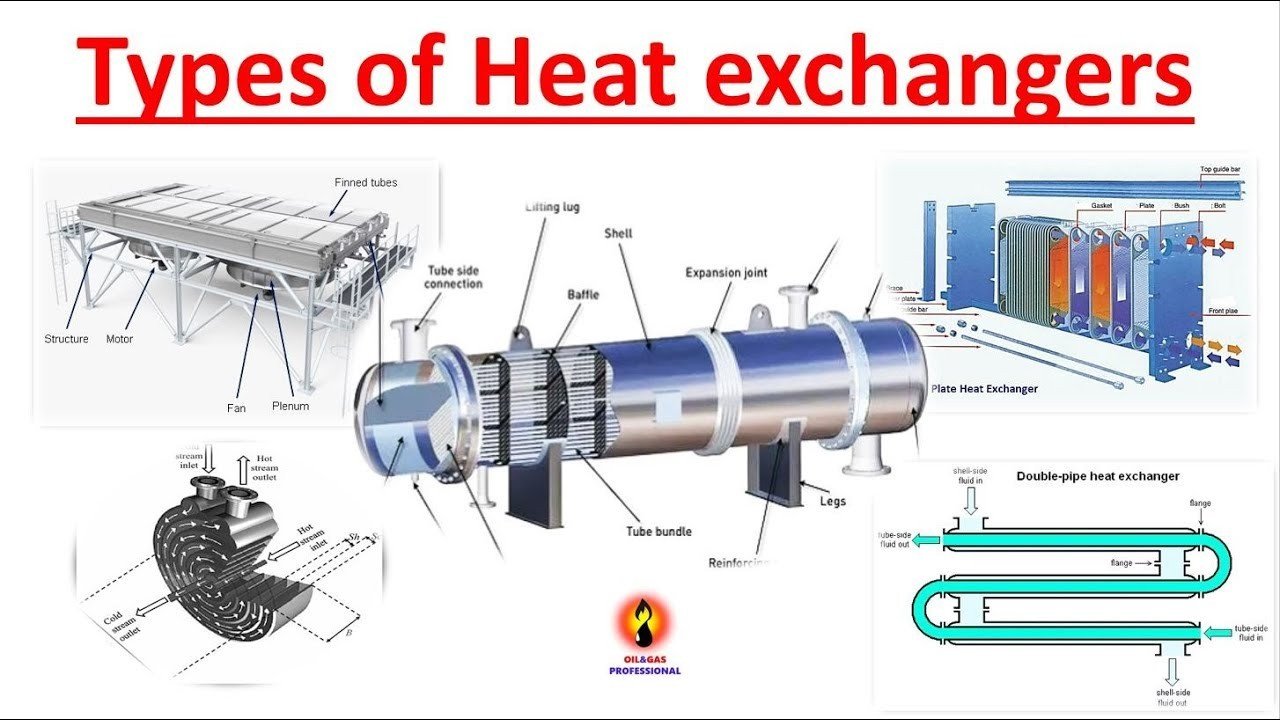

- Seawater heat exchanger tubes

- Subsea riser piping and umbilicals

- Fertilizer plant scrubber tubes

- Nuclear reactor control and fuel assemblies

- Exhaust ducting in aerospace and turbine engines

- Hydrogen chloride handling and flue gas scrubbers

- Boiler feedwater and steam lines in power plants

More info: Heat exchanger – Wikipedia

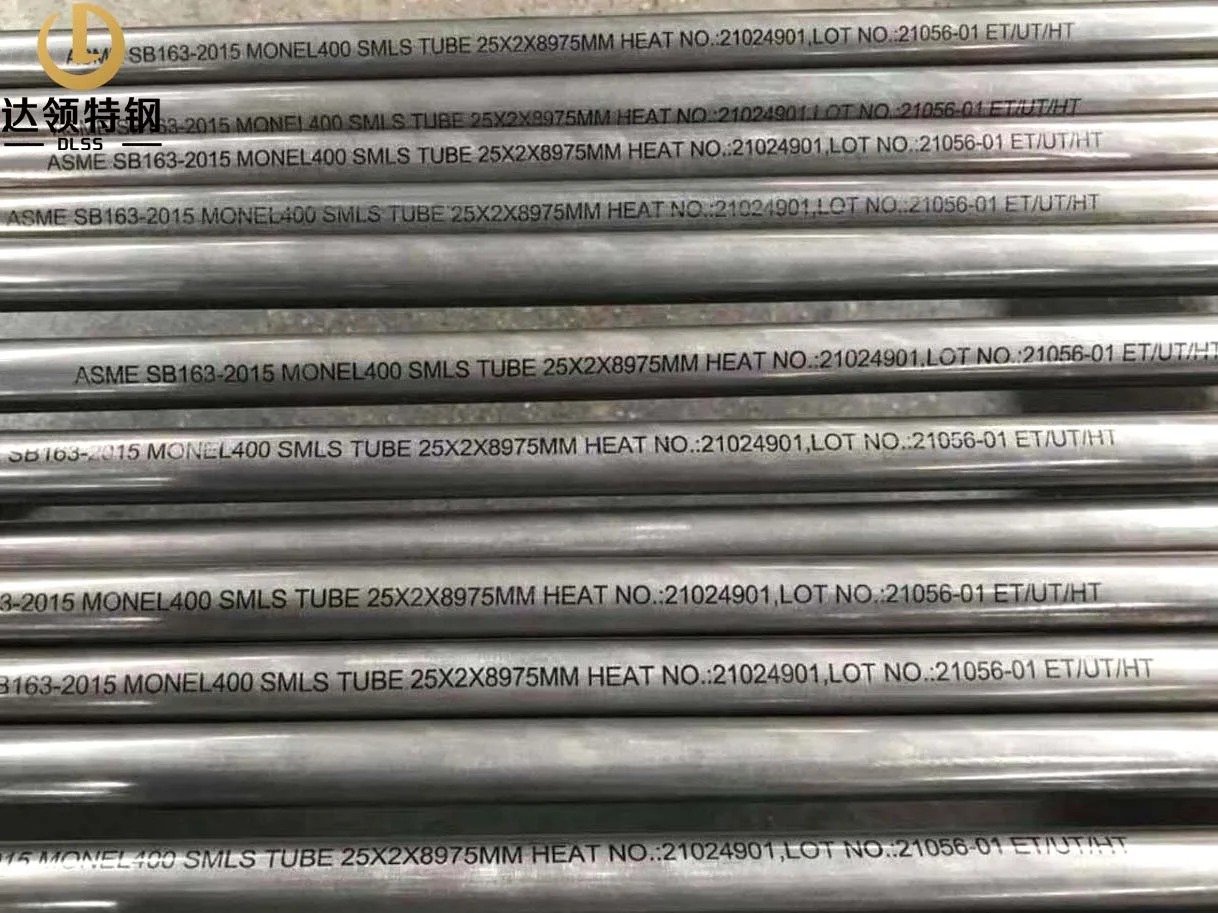

Manufacturing Standards

- ASTM B444 – Seamless, cold-worked, Inconel 625 pipe

- ASME SB-444 – Pressure vessel application

- NACE MR0175 / ISO 15156 – Sour service compliance

- Third-party inspection: SGS, TUV, BV

- Certifications: EN10204 3.1 / 3.2, PMI, Hydrotest, NDT reports

Keyword targets: ASTM B444 tube, N06625 pipe supplier, NACE compliant nickel tube

Why Choose Inconel 625 Over 316L or Duplex?

| Property | Inconel 625 | 316L SS | Duplex 2205 |

|---|---|---|---|

| Max Temp Resistance | ~980°C | ~550°C | ~600°C |

| Pitting Resistance | Excellent | Moderate | Good |

| Chloride SCC Resistance | Excellent | Limited | Better than 316L |

| Weldability | Excellent | Good | Requires care |

If you are operating in seawater, acid gas, or high-pressure steam, Inconel 625 outperforms almost all common stainless steels.

DLSS – Your Inconel 625 Seamless Tube Supplier

DLSS supplies cold-drawn and cold-rolled Inconel 625 seamless tubes for demanding industries. Product specifications include:

- Outer Diameter: 6 mm to 60 mm

- Wall Thickness: 0.7 mm to 6 mm

- Surface Finish: Bright annealed or pickled

- Form: Straight, U-bent, or coiled

- Packing: Seaworthy plywood crates with plastic end caps

Website: www.dlsspipe.com

Email: info@dlsspipe.com

Frequently Asked Questions (FAQ)

Q1: What makes Inconel 625 ideal for seawater applications?

A: Its high molybdenum and chromium content provides superior pitting resistance in chloride-rich environments.

Q2: Can DLSS provide tubes with NACE MR0175 compliance?

A: Yes. Tubes for sour gas service are available with NACE and ISO 15156 documentation.

Q3: What is the minimum order quantity for Inconel 625 seamless tubes?

A: Typically 50–100 meters depending on size and specification.