Ultrasonic testing tube inspection is a critical non-destructive method used in the stainless steel tube industry to ensure product quality, safety, and compliance with international standards. Especially in industries such as heat exchangers, boilers, power plants, and oil & gas, even the smallest internal defect can lead to costly failures or system breakdowns.

This article explains what ultrasonic tube inspection is, how it works, and why DLSS uses automated UT systems to maintain the highest level of tube integrity.

1. What Is Ultrasonic Testing Tube Inspection?

Ultrasonic testing (UT) is a non-destructive testing technique that uses high-frequency sound waves to detect internal and surface defects in metal tubes. It helps manufacturers locate flaws like cracks, voids, inclusions, and laminations—without cutting or damaging the product.

In tube manufacturing, UT is often performed after cold drawing and annealing, ensuring full inspection before final shipment.

Learn more from this external reference:

NDT Resource Center – Ultrasonic Testing

2. How Does Ultrasonic Testing Work for Tubes?

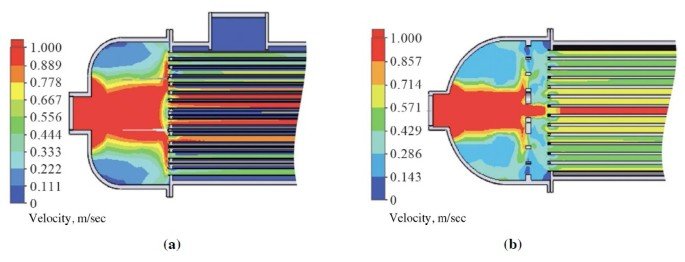

The inspection process works as follows:

- A transducer emits ultrasonic waves into the stainless steel tube.

- If the waves encounter a flaw, they reflect differently.

- These reflections are analyzed in real time to locate and size any discontinuities.

DLSS uses fully automated ultrasonic testing systems that scan the entire tube length, covering:

- Inner and outer wall integrity

- Longitudinal and transverse defects

- Thickness measurement and concentricity

- Seam weld verification (if applicable)

3. Why Ultrasonic Tube Inspection Is So Important

Reason 1: Early Detection of Internal Defects

UT can detect flaws that visual inspection and eddy current testing may miss—especially subsurface or internal volumetric defects.

Reason 2: Compliance with Global Standards

Many industries require ultrasonic testing as part of mandatory specifications, including:

- ASTM A450 / A999

- EN 10246

- ISO 10893

- ASME Section V

Reason 3: Non-Destructive and Accurate

Unlike destructive sampling, UT doesn’t damage the product. It ensures 100% inspection coverage with traceable results.

Reason 4: Process Optimization and Waste Reduction

Real-time UT data helps adjust production in case of systematic issues—minimizing scrap and rework.

Reason 5: Customer Assurance and Certification

DLSS provides full ultrasonic test reports with:

- Test range and sensitivity

- Signal responses

- Tube acceptance status

Clients gain peace of mind knowing every tube has passed rigorous inspection.

4. DLSS Ultrasonic Testing Capabilities

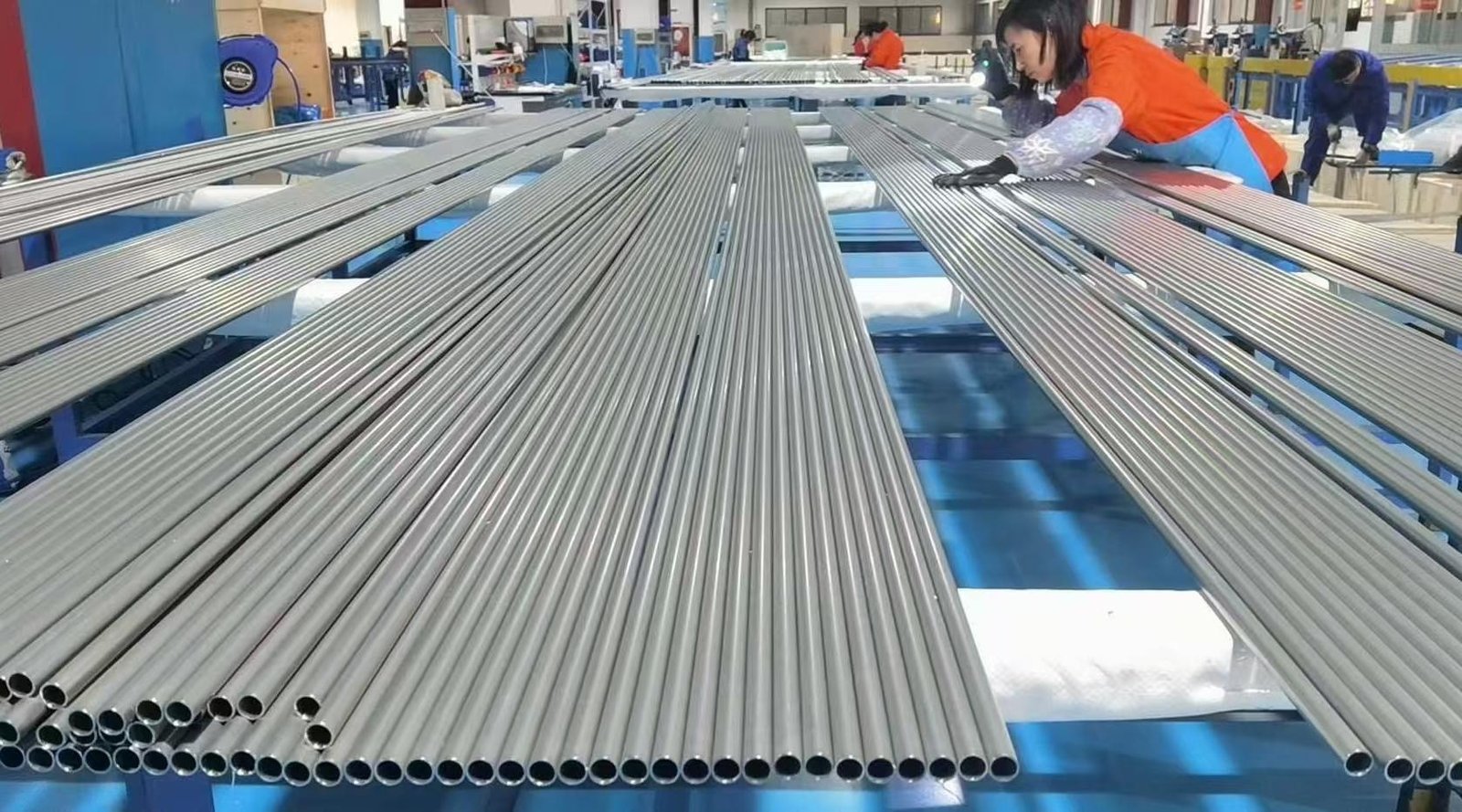

At DLSS, we apply ultrasonic testing on stainless steel tubes ranging from:

- Outer diameter: 6 mm to 60 mm

- Wall thickness: 0.5 mm to 5.0 mm

- Sensitivity: FBH (Flat Bottom Hole) Ø 0.8 mm and above

- Standards: ASTM, EN, and custom client specifications

Our UT system is fully integrated into the finishing line and supports third-party witness inspection (TÜV, SGS, BV).

Visit: DLSS Heat Exchanger Tubes

5. Where UT-Inspected Tubes Are Used

Stainless steel tubes with ultrasonic testing are essential in:

- Shell & tube heat exchangers

- Boilers and pressure vessels

- Pharmaceutical and food-grade equipment

- Chemical injection and process lines

- Power generation and nuclear piping

Frequently Asked Questions (FAQ)

Q: Can UT detect both surface and internal flaws?

Yes. UT detects subsurface, internal, and surface-breaking flaws—unlike visual inspection or eddy current testing which have limited depth.

Q: Do you provide UT documentation with shipments?

Absolutely. DLSS supplies UT reports, test certificates, and data logs upon request.

Q: Is UT better than eddy current testing?

For internal or volumetric flaws, yes. Eddy current is excellent for surface cracks, but UT is required when internal quality is critical.

Conclusion

Ultrasonic testing tube inspection is no longer optional—it’s a requirement for modern stainless steel tube manufacturing. At DLSS, we combine advanced UT equipment with decades of technical experience to ensure your tubes meet the strictest quality, safety, and regulatory standards.

Contact us: info@dlsspipe.com

Visit our website: www.dlsspipeline.com