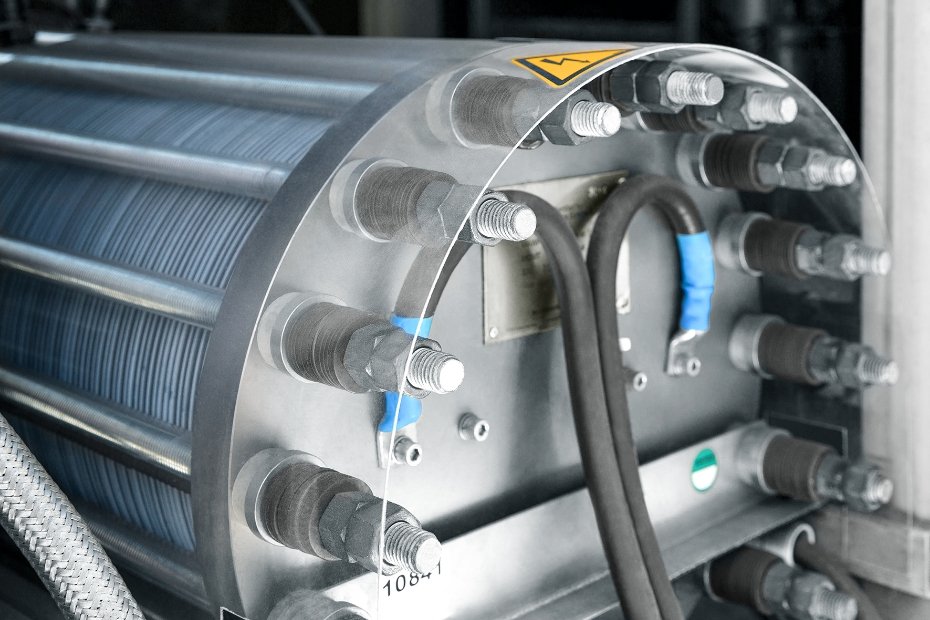

At DLSS (Zhejiang Daling Special Steel Co., Ltd.), we take pride in transforming customer requirements into high-performance stainless steel solutions. Recently, we successfully fulfilled a custom order for Super Duplex Stainless Steel (UNS S32750) Tie Rods and Hex Nuts, tailored precisely to our client’s technical drawings and application needs.

Project Overview

- Product: Tie Rods and M12 Hex Nuts

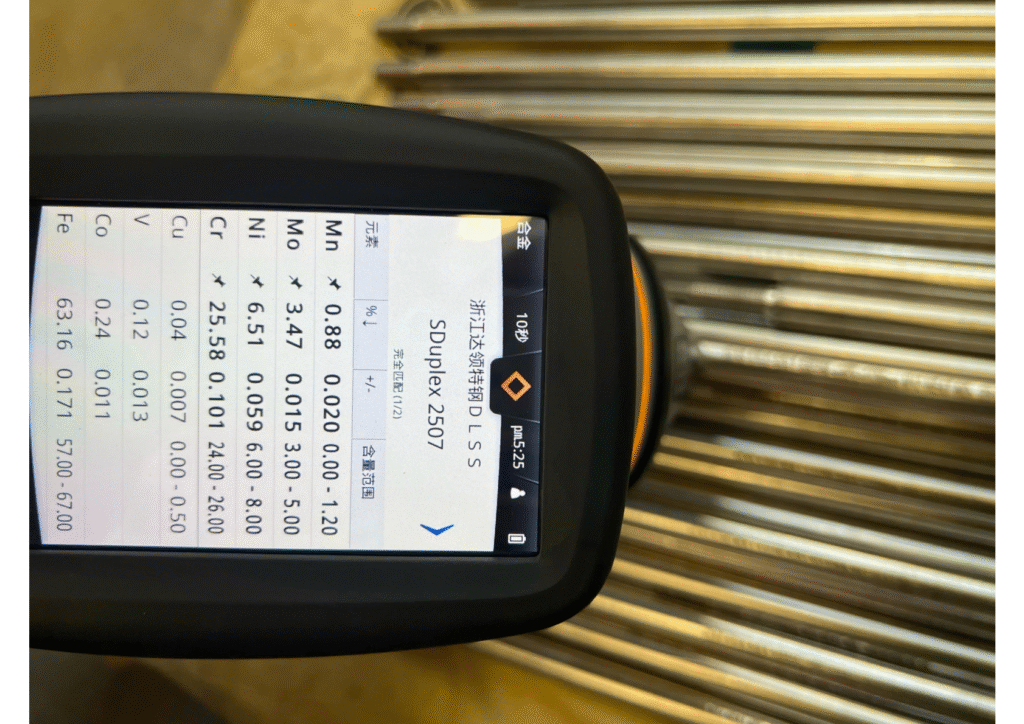

- Material: Super Duplex Stainless Steel – UNS S32750

- Standard: ASTM A182 for Forged Components

- Quantity: 30 Tie Rods + 100 Hex Nuts

- Manufacturing Process: Precision machining from forged bars

- Delivery: On-time and in full compliance with client specifications

Strict Quality Requirements Met

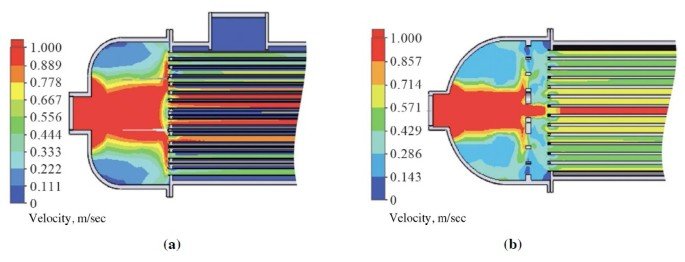

To meet our customer’s demanding standards, DLSS implemented full-process quality control according to the following special requirements:

- Material: Super Duplex Stainless Steel S32750 as per ASTM standards. All elements and properties strictly comply with requirements:

- Yield Strength ≥ 550 MPa

- Tensile Strength ≥ 800 MPa

- Manufacturing Specification:

- Stud bolts are strictly produced according to client drawings.

- No welds or joints are allowed (fully seamless).

- Length tolerance must strictly follow the contract; no undersizing is allowed.

- Straightness tolerance: 0 to +0.8 mm per meter.

- Finish & Protection:

- All components are precision-machined with smooth threads.

- No surface defects allowed: no dents, cracks, or impact marks.

- Each finished product is individually protected with wire mesh sleeves.

- Nuts must be able to screw smoothly into the stud thread zone.

These high-standard expectations required extreme precision during both material selection and CNC machining. DLSS successfully achieved them through advanced equipment, strict process control, and experienced QA inspection.

Why Super Duplex UNS S32750?

Super Duplex Stainless Steel (SDSS) combines excellent corrosion resistance with superior mechanical strength, making it ideal for applications exposed to chloride-rich or highly corrosive environments, such as:

- Offshore platforms

- Seawater desalination systems

- Chemical processing equipment

- Pressure vessels and flanged joints

Client Satisfaction

Our customer acknowledged the quality and precision of the components. By adhering to international material standards and applying rigorous quality control throughout the process, we ensured our client received a product they can rely on for high-stakes engineering applications.

“DLSS turned our drawings into reality. The precision and quality speak for themselves.” – Customer Feedback

Our Commitment

At DLSS, we specialize in stainless steel seamless pipes, heat exchanger tubes, and high-spec custom machined parts. Whether it’s standard delivery or tailored production based on complex drawings, our engineering team is ready to support your success.

Want to learn more or request a quote?

Email: info@dlsspipe.com

Website: www.dlsspipe.com