1. Introduction

Industries handling aggressive chemicals such as sulfuric acid, hydrochloric acid, and phosphoric acid face constant challenges in piping material selection. Hastelloy C-276 (Alloy C-276) pipes are one of the most reliable choices for these corrosive environments. With outstanding resistance to strong oxidizers, reducing agents, and mixed chemical streams, Alloy C-276 tubes have become the industry standard for acid processing facilities worldwide.

2. Properties of Hastelloy C-276

- Standard Reference: ASTM B622 / B619 / B626

- Composition: Nickel (Ni) ~57%, Molybdenum (Mo) ~16%, Chromium (Cr) ~15%, with tungsten and iron.

- Key Characteristics:

- Excellent resistance to oxidizing and reducing acids.

- Outstanding pitting and crevice corrosion resistance.

- Superior resistance to stress corrosion cracking (SCC).

- Maintains strength and ductility at high temperatures.

Reference: Hastelloy C-276 – Wikipedia.

3. Why Alloy C-276 is Ideal for Acid Processing

Acid production and processing involve extremely aggressive environments where stainless steel or even duplex grades may fail. Alloy C-276 solves these challenges by offering:

- Long-term reliability in concentrated sulfuric, hydrochloric, and phosphoric acid environments.

- Resistance to chlorine dioxide, wet chlorine gas, and ferric/ cupric chloride conditions.

- High mechanical strength, enabling thinner walls and lighter piping systems.

- Extended service life compared with 316L, 904L, or even Alloy 20 stainless steel.

4. Applications of Alloy C-276 Pipes in Acid Industries

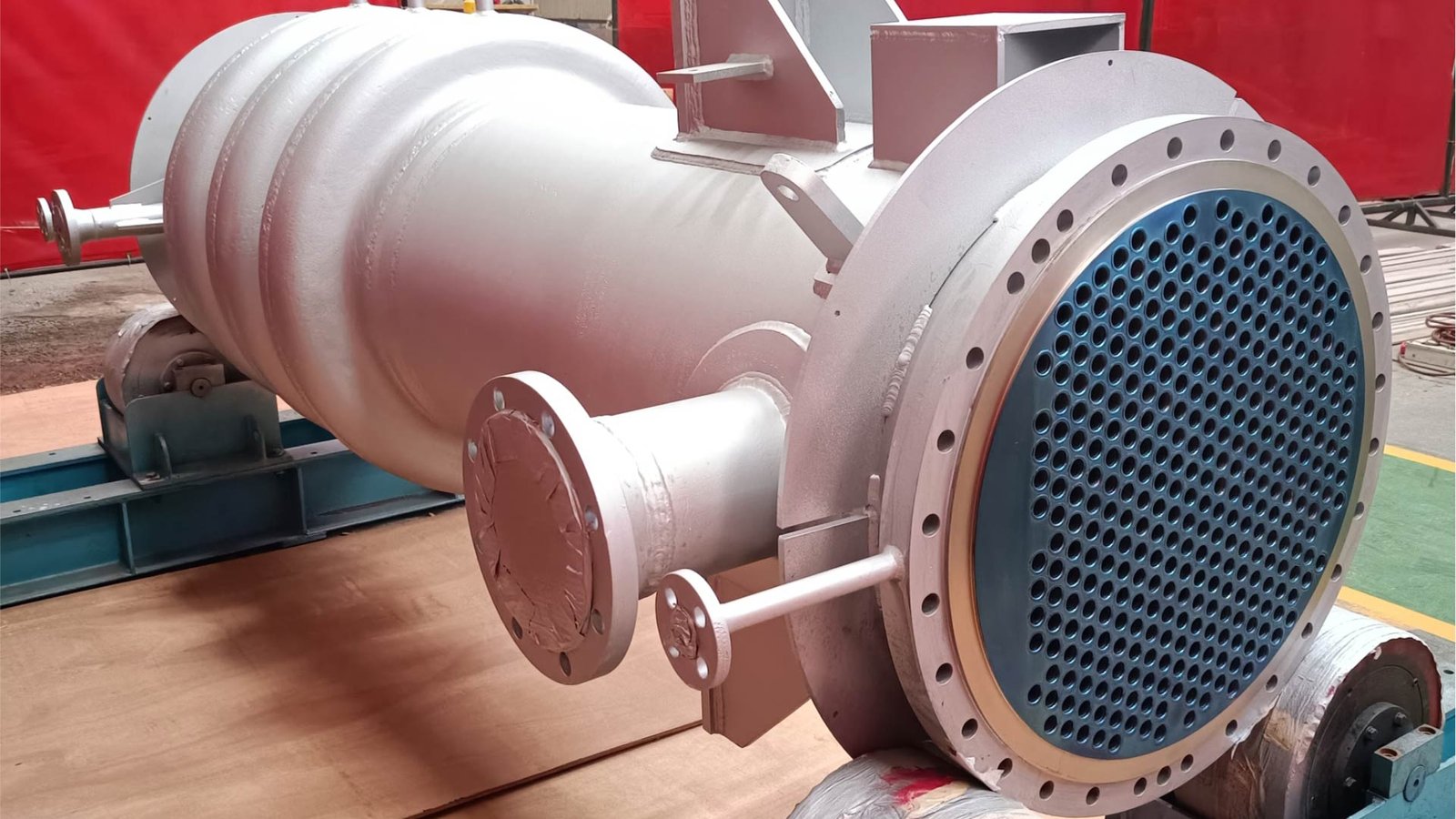

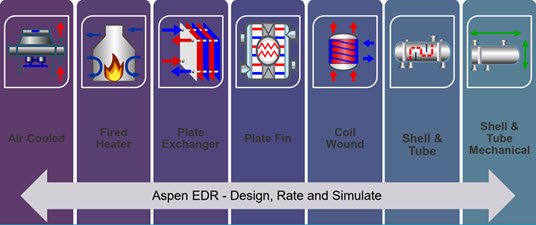

- Sulfuric acid plants – absorption towers, distribution piping, and heat exchangers.

- Phosphoric acid plants – piping systems for wet-process streams.

- Hydrochloric acid production – gas scrubbers, ducting, and chemical reactors.

- Chlor-alkali plants – piping systems handling brine and chlorine dioxide.

- Mixed acid environments – processes involving nitric and sulfuric acid mixtures.

5. Alloy C-276 vs Alternative Materials

| Property / Material | Alloy C-276 | Stainless Steel 316L | Duplex Steel 2205 | Alloy 20 |

|---|---|---|---|---|

| Corrosion Resistance (Strong Acids) | Excellent | Poor | Moderate | Good |

| Pitting / Crevice Resistance | Outstanding | Weak | Moderate | Good |

| SCC Resistance | Excellent | Weak | Moderate | Good |

| Service Life | 20+ years | 2–5 years | 5–8 years | 10–15 years |

| Cost | High | Low | Medium | Medium |

6. DLSS Supply Capabilities

At DLSS, we manufacture and supply Alloy C-276 pipes and tubes with:

- Compliance to ASTM B622 / B619 / B626 standards.

- Product forms: seamless pipes, welded pipes, tubes, U-bend tubes.

- Third-party inspection by TÜV, DNV, LR, ABS.

- Traceable MTC (EN 10204 3.1/3.2).

- Custom dimensions and urgent delivery for acid plant projects.

- Export packaging: seaworthy wooden crates with capped ends and anti-corrosion treatment.

7. Conclusion & Call to Action

For industries where acid corrosion is a daily challenge, Hastelloy C-276 pipes provide unmatched performance and long-term reliability. By investing in Alloy C-276, acid processing plants reduce unplanned downtime, lower maintenance costs, and ensure safety and compliance.

Contact DLSS today for technical support, datasheets, and quotations.

info@dlsspipe.com | www.dlsspipeline.com