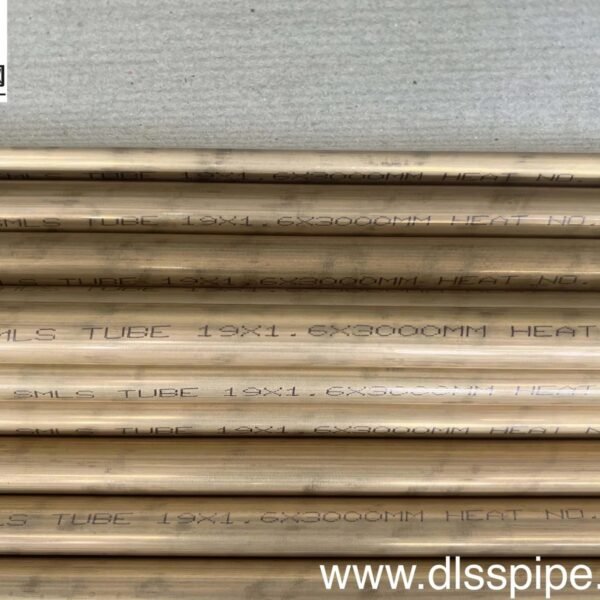

Product Overview: ASTM B111 C68700 Aluminum Brass Seamless Tube (19×1.6mm, 3000mm)

C68700 Aluminum Brass, also known as Al-Brass, is a copper-zinc alloy enhanced with a small amount of aluminum. It is widely recognized for its exceptional resistance to dezincification, corrosion, and biofouling, especially in seawater and brackish water environments. This makes it one of the most trusted materials for condenser tubes, heat exchangers, and marine applications.

The featured tube, with an outer diameter of 19mm, wall thickness of 1.6mm, and length of 3000mm, is manufactured in accordance with ASTM B111, fully tested using 100% Eddy Current Testing (ECT) to ensure non-destructive integrity verification.

Product Specifications

- Standard: ASTM B111 / ASME SB111

- Material Grade: C68700 (Aluminum Brass), annealed temper (O61)

- Outside Diameter (OD): 19.0 mm

- Wall Thickness (WT): 1.6 mm

- Length: 3000 mm

- Tube Type: Seamless

- Surface Condition: Smooth, clean, and oxide-free

- Testing: 100% Eddy Current Testing for flaw detection

- End Options: Plain or beveled, capped and protected for export

Chemical Composition of C68700 (Typical)

| Element | Content (%) |

|---|---|

| Copper (Cu) | 76.0 – 79.0 |

| Zinc (Zn) | Remainder |

| Aluminum (Al) | 1.8 – 2.5 |

| Iron (Fe) | ≤ 0.06 |

| Tin (Sn) | ≤ 0.07 |

| Arsenic (As) | 0.02 – 0.06 |

| Lead (Pb) | ≤ 0.05 |

Aluminum improves the alloy’s resistance to impingement and erosion-corrosion. Arsenic inhibits dezincification — a common issue in traditional brass under marine conditions.

Mechanical Properties (Annealed O61 Temper)

| Property | Value |

|---|---|

| Tensile Strength | ≥ 310 MPa |

| Yield Strength | ≥ 105 MPa |

| Elongation (in 5D) | ≥ 30% |

| Hardness (HRB) | ≤ 65 |

| Thermal Conductivity | ~121 W/m·K |

| Max Working Temp | ~400°C (752°F) |

These properties make C68700 tubes an excellent fit for thermal exchange and pressure-resisting systems.

Applications of C68700 Aluminum Brass Tubes

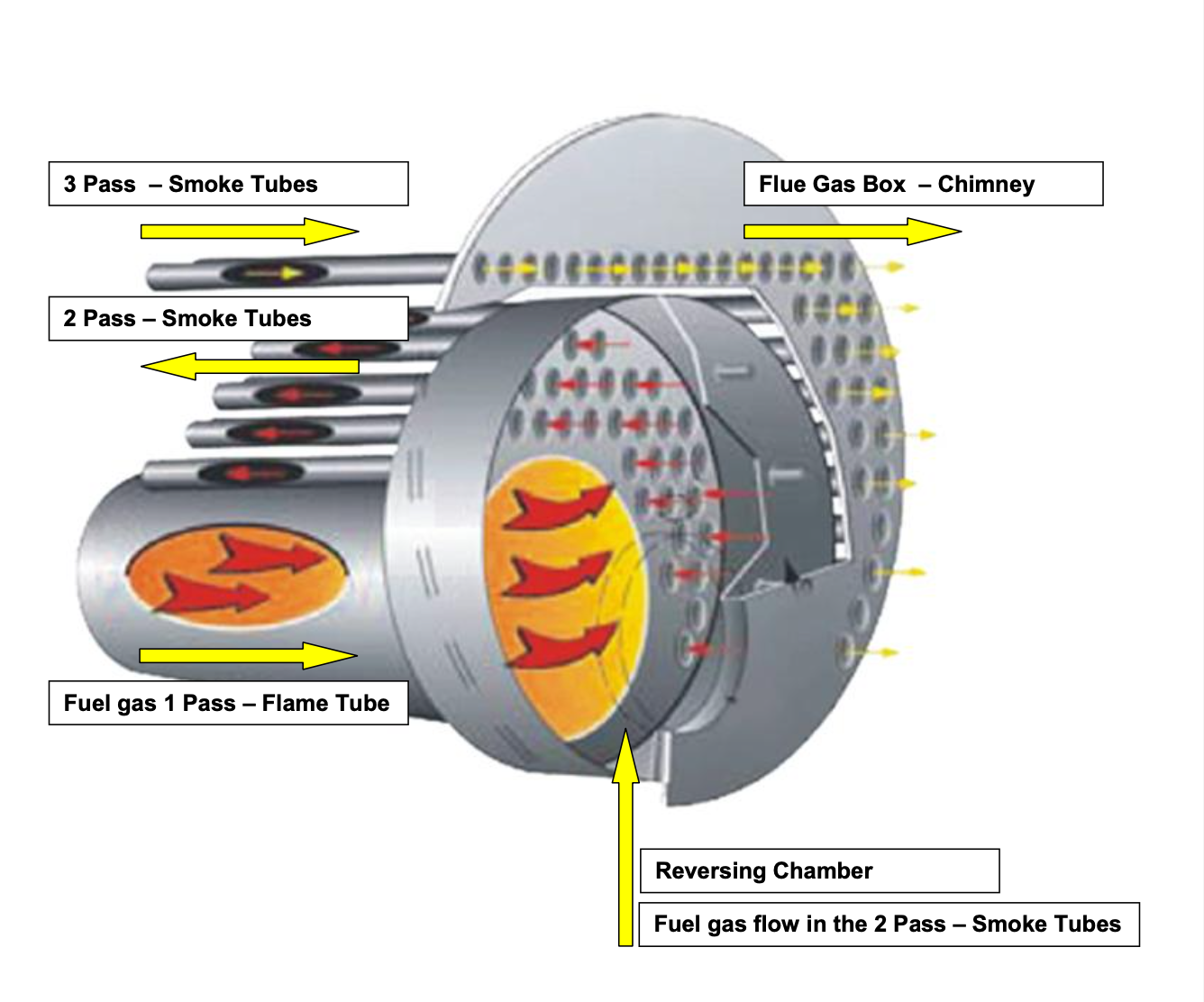

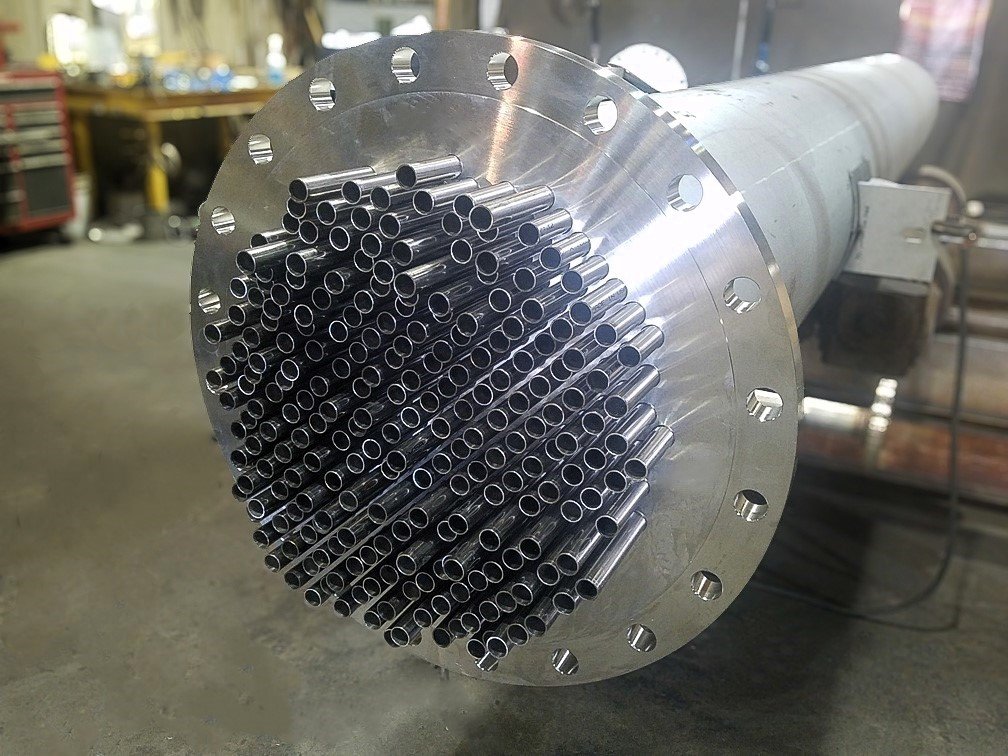

1. Condenser Tubes

The most common application. C68700 tubes are ideal for steam condenser systems in power plants, thanks to their heat transfer efficiency and resistance to corrosion from cooling water (including seawater and polluted river water).

2. Seawater Desalination Plants

With high biofouling and impingement resistance, these tubes are used in multi-stage flash (MSF) and reverse osmosis (RO) systems.

3. Heat Exchangers and Coolers

Used in oil refineries, HVAC systems, and shipbuilding for transferring heat between fluids without degradation over time.

4. Marine Engineering

Perfect for marine hardware and piping exposed to salty, aggressive environments.

Eddy Current Testing (ECT): 100% Non-Destructive Assurance

Every tube undergoes 100% eddy current testing, a non-destructive inspection method that detects:

- Internal or external cracks

- Pinhole leaks

- Wall thickness inconsistencies

- Structural discontinuities

This ensures each tube is flaw-free before reaching the client — particularly critical for condenser and pressure systems where performance and safety are paramount.

Why Choose ASTM B111 C68700 Aluminum Brass Tubes?

| Feature | Benefit |

|---|---|

| High Corrosion Resistance | Ideal for seawater, industrial water, and polluted water systems |

| Excellent Thermal Conductivity | Maximizes heat transfer efficiency in condensers |

| Non-Sparking & Non-Magnetic | Suitable for specialized industrial environments |

| Proven Reliability | Used in thousands of power plants and marine systems globally |

| Tested to the Core | 100% Eddy Current Testing ensures structural integrity |

Packaging & Logistics

- Packing Method: Tubes are sealed with plastic end caps, bundled with moisture-proof wrapping, and packed in export-grade wooden cases.

- Marking: Size, grade, standard, heat number, and inspection code are clearly marked on each tube and bundle.

- Delivery: Worldwide shipping options available (sea/air freight), with flexible minimum order quantities.

Call to Action

Need Condenser Tubes That Last?

DLSS offers Aluminum Brass C68700 seamless tubes with full ASTM B111 compliance and 100% eddy current testing — ensuring quality, performance, and peace of mind.

Request a quote today or speak with our sales engineer:

Visit: www.dlsspipeline.com

Email: info@dlsspipe.com

Let us help you build systems that last — with material that performs.