Meta Description:

The oil & gas industry demands corrosion-resistant, high-pressure-rated piping solutions. Learn how to select the best pipe materials for upstream, midstream, and downstream applications.

Introduction

In the oil and gas sector, pipelines are more than just infrastructure—they are lifelines of the operation. From offshore rigs and sour gas fields to refineries and LNG terminals, the performance of pipe materials directly affects safety, uptime, and profitability.

This article dives into the most trusted pipe materials used across the industry, what standards guide their selection, and how suppliers like DLSS help ensure reliability in even the harshest environments.

What Makes Oil & Gas Applications So Demanding?

Pipeline systems in this industry face some of the toughest operating conditions:

- High pressure & high temperature environments

- Corrosive fluids, including hydrogen sulfide (H₂S), CO₂, chlorides

- Sour service requirements with SSC (Sulfide Stress Cracking) concerns

- Remote or subsea access, making failure extremely costly

To withstand this, engineers must balance mechanical strength, corrosion resistance, code compliance, and cost.

Key Material Standards in the Oil & Gas Sector

Before selecting materials, it’s important to understand the standards involved. The most common ones include:

- ASTM A213 / A312 – Seamless stainless tubes and pipes

- ASTM B111 / B423 – Non-ferrous alloy tubes (e.g. Admiralty Brass, Incoloy 825)

- API 5L – Line pipes for transportation of oil, gas, water

- ASME B31.3 – Process piping in refineries and gas plants

- NACE MR0175 / ISO 15156 – Material requirements for H₂S-containing environments

Top Pipe Materials Used in Oil & Gas

Here’s a breakdown of the most popular and reliable pipe materials across oil & gas operations:

1. TP316L (UNS S31603)

- Excellent general corrosion resistance

- Widely used in offshore platforms, separators, process lines

- Low carbon version reduces risk of weld decay

2. TP321 / TP347H

- Stabilized grades for high-temperature service

- Ideal for heater coils, reformer tubes, and thermal systems

3. Incoloy 825 (UNS N08825)

- Superior resistance to acids and chlorides

- Used in sour gas service, especially where H₂S and CO₂ are present

- NACE MR0175 compliant

4. Duplex Stainless Steel (S31803 / S32750)

- Double the yield strength of 316L

- Resistant to chloride pitting and stress corrosion

- Ideal for subsea, seawater injection, risers

5. Admiralty Brass (C44300)

- Used in condensers and oil refinery cooling systems

- Combines cost-effectiveness with corrosion resistance

Application Examples Across Oil & Gas Segments

| Segment | Application | Material Suggestion |

|---|---|---|

| Upstream | Offshore risers, separators, wellheads | S32750, Incoloy 825, TP316L |

| Midstream | Gathering lines, compressor stations | API 5L X52, Duplex, A106 Gr B |

| Downstream | Refinery heaters, process piping | TP321, TP347H, Alloy 825 |

| LNG Terminals | Low-temp cryogenic lines | TP304L, A333 Gr 6, Inox alloys |

| Gas Fields | Sour service pipelines | NACE-compliant Duplex, 825 |

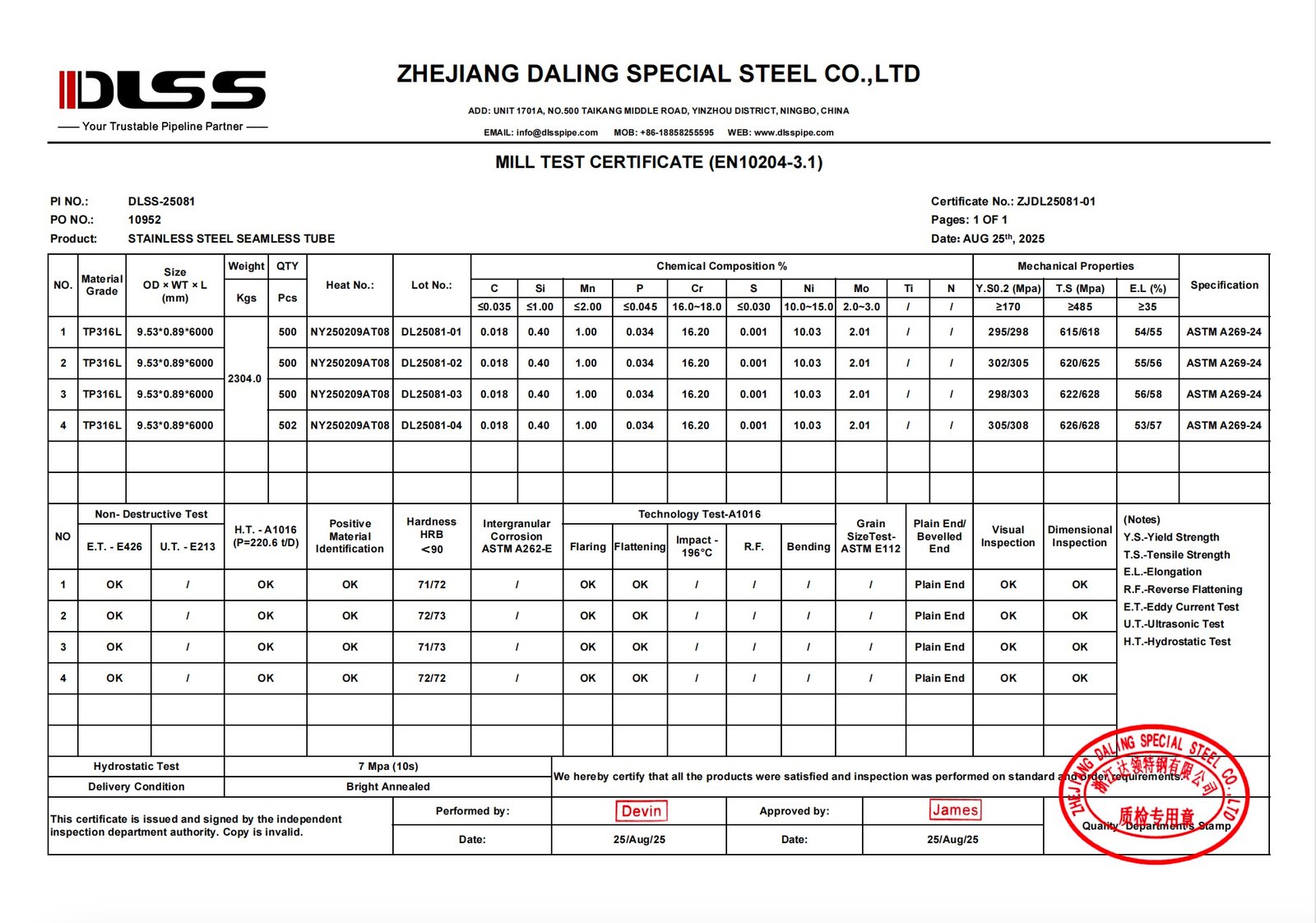

How DLSS Supports the Oil & Gas Sector

DLSS provides full-range piping solutions that meet the exacting requirements of oil and gas projects:

- Seamless stainless pipes from OD 6mm to 219mm

- Grades include TP304L, TP316L, TP321, Duplex 2205, Incoloy 825

- Pickled, BA, EP, and passivated surfaces

- Third-party inspection available (SGS, BV, TUV)

- Documentation: EN 10204 3.1 / 3.2, NACE certification, PMI test reports

Our project experience includes refinery upgrades in Turkey, offshore gas lines in Southeast Asia, and petrochemical plants in the Middle East.

Conclusion

The right pipe material isn’t just a technical choice—it’s a business-critical decision.

By choosing certified, tested, and appropriate piping materials, oil & gas operators can ensure system reliability, protect human safety, and extend the lifespan of critical infrastructure.

DLSS helps you meet these goals with global supply capability, strict quality standards, and a deep understanding of pipeline engineering.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com