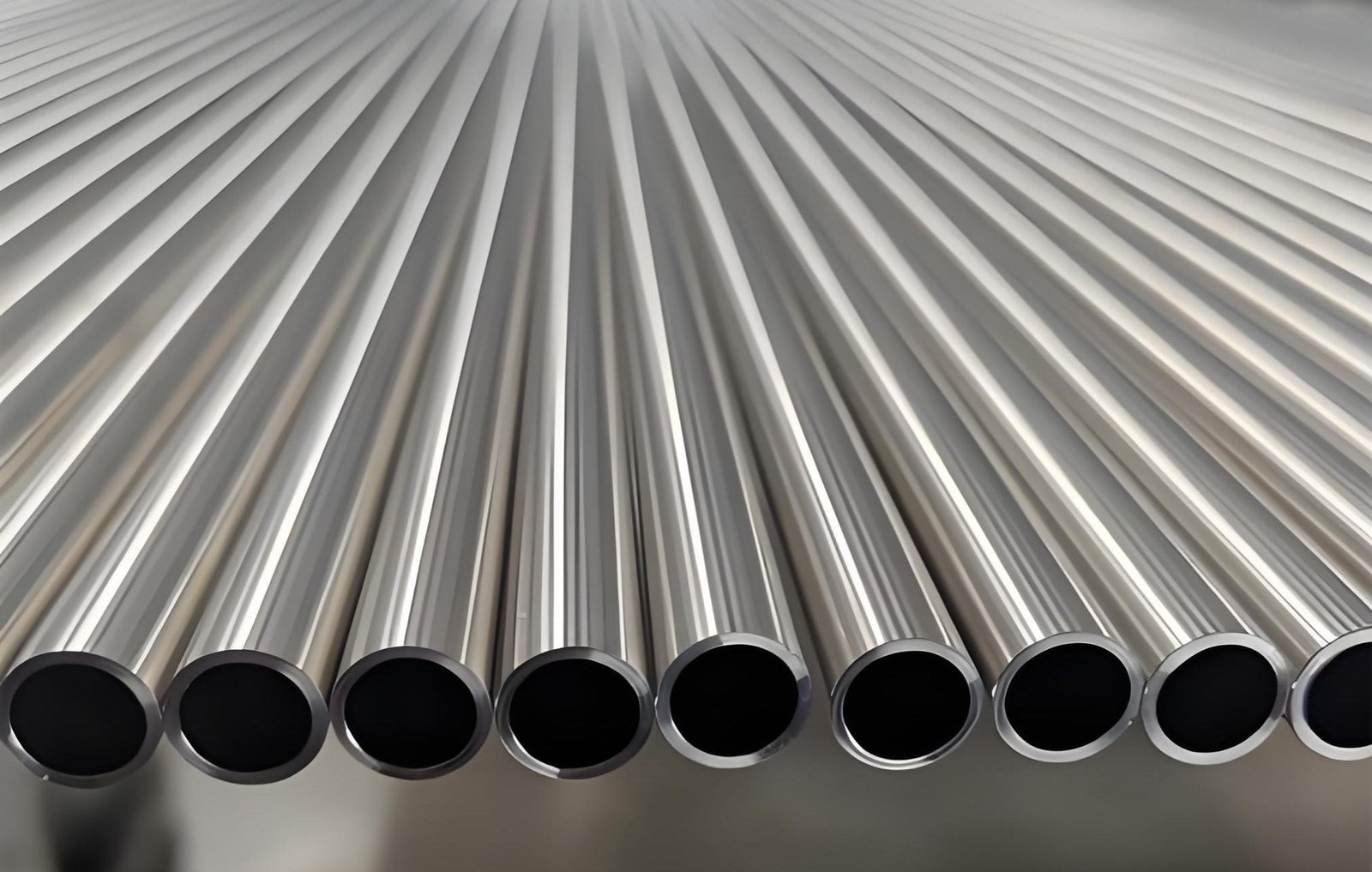

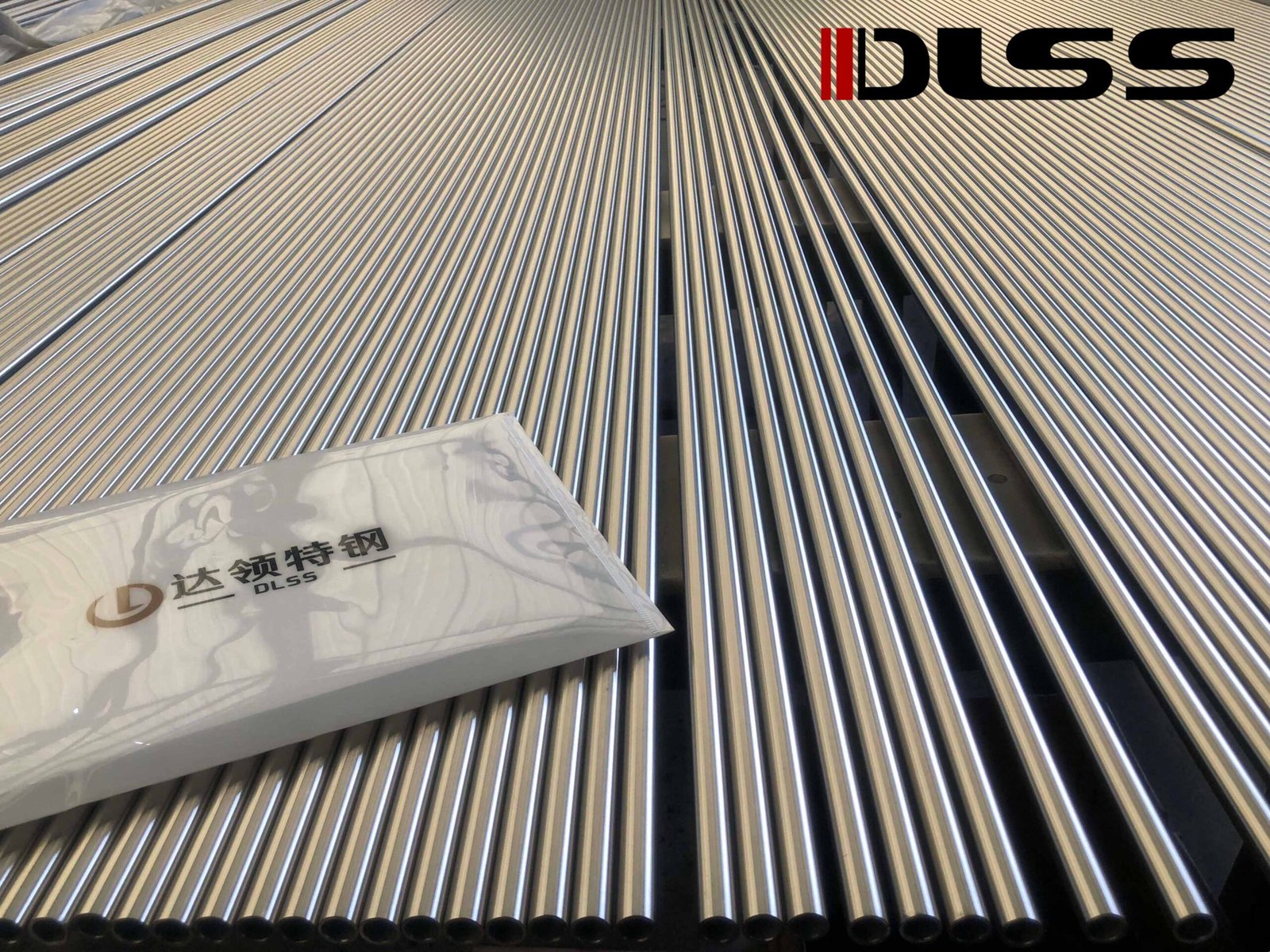

Electropolished (EP) Stainless Steel Tubes: The Key to High-Purity Piping Systems

Updated: October 6, 2025 · Author: DLSS Technical Team

In high-purity industries — from semiconductor wafer fabrication to pharmaceutical cleanrooms — even microscopic surface roughness can harbor contaminants and compromise sterile operations. That’s why electropolished (EP) stainless steel tubes have become the preferred choice for ultra-clean process piping. At DLSS, we manufacture high-purity 316L/304L EP tubes that comply with ASME BPE, ASTM A269, and ASTM A270 requirements.

What Is an Electropolished (EP) Tube?

Electropolishing is an electrochemical finishing process that removes a thin, controlled layer from stainless steel. The tube acts as an anode in an electrolyte; current preferentially dissolves surface asperities, creating a mirror-bright, ultra-smooth inner surface and a chromium-rich passive film for superior corrosion resistance.

- Typical inner surface roughness: Ra ≤ 0.20 μm (per ASME BPE guidance)

- Grades: 316L (1.4404), 304L (1.4307), 321 (1.4541) upon request

- Standards: ASTM A269/A270 (S2), EN 10357, DIN 11866

Technical Advantages Backed by Data

| Property | Electropolished Tube (EP) | Mechanically Polished (MP) | Bright Annealed (BA) |

|---|---|---|---|

| Inner Surface Roughness (Ra) | ≤ 0.20 μm | 0.40–0.80 μm | 0.50–0.80 μm |

| Corrosion Resistance | Excellent (enhanced passive film) | Moderate | Good |

| Cleaning Validation | Easy (lower TOC/rouge) | Difficult | Moderate |

| Flow Resistance | Minimal (supports laminar flow) | Higher | Moderate |

| Visual Finish | Mirror | Satin | Bright metallic |

Data references: ASME BPE 2022; DLSS profilometer tests (typical inner Ra ≈ 0.18 μm).

Why EP Tubes Matter for High-Purity Systems

1) Ultra-High Cleanliness

Electropolishing removes embedded iron and inclusions, reducing Total Organic Carbon (TOC) and rouge formation — essential for validation in regulated environments (see FDA guidance and cGMP practices).

2) Better Corrosion Resistance

EP surfaces show a higher Cr/Fe ratio and a more stable passive layer, extending lifecycle under aggressive CIP/SIP regimes.

3) Improved Flow Dynamics

Ultra-smooth surfaces minimize turbulence and particle shedding — critical for UPW and process gases in fabs and biotech facilities.

4) Lower Bacterial Adhesion

Technical notes from Swagelok and data from the Semiconductor Industry Association indicate substantially reduced microbial adhesion on electropolished 316L vs. mechanically finished surfaces.

Typical DLSS Specifications

| Grades | ASTM A270 TP316L / ASTM A269 TP304L / EN 1.4404 |

| Size Range | OD 6–219 mm; WT 0.5–3.0 mm; length up to 12 m |

| Surface Roughness | Inner ≤ 0.20 μm; outer ≤ 0.40 μm |

| Testing | 100% ET + UT + VT; Ra measurement; PMI; optional He leak test |

| Certifications | ISO 9001/14001; PED 2014/68/EU; AD2000-W0; third-party (DNV, BV, LR) |

| Packaging | Cleanroom PE bag + end caps; batch labels; optional N2 purge |

Applications

- Pharmaceutical water systems (PW/WFI/USP)

- Semiconductor gas & chemical distribution

- Biotech and laboratory fluid lines

- Food & beverage sterile production

- High-vacuum and cryogenic equipment

Market drivers: the global stainless steel tube market is projected to reach USD 57.4 billion by 2030, fueled by high-purity and hygienic processing demand.

EP vs. BA Tubes — Quick Selection Guide

| Feature | EP Tube | BA Tube | Recommended Use |

|---|---|---|---|

| Cleanliness | Ultra-high | Industrial-grade | EP for pharma/semiconductor; BA for heat exchangers/general |

| Inner Ra | ≤ 0.20 μm | 0.50–0.80 μm | Choose EP when CIP/SIP and validation are required |

| Cost | Higher | Lower | Balance budget vs. compliance needs |

Why Choose DLSS

- 30+ years in precision tubing; global deliveries to 40+ countries

- ASME BPE / ASTM A270 S2 / DIN 11866 compliant EP finishes

- Automated electropolishing lines with profilometer verification

- OEM customization: inner Ra 0.13–0.25 μm; bespoke lengths & packaging

- Full traceability and independent TPI (DNV, BV, LR, CCS)

Related DLSS Products & Resources

Request a Quote Email: info@dlsspipe.com

Standards & References

- ASME BPE – Bioprocessing Equipment

- ASTM A269 – Austenitic Stainless Steel Tubing

- ASTM A270 – Sanitary Tubing

- FDA – cGMP/Cleanroom Guidance

- Swagelok – What Is Electropolishing?

- Semiconductor Industry Association (SIA)

- Wikipedia – Electropolishing

- Grand View Research – Stainless Steel Tubes Market

FAQ: Electropolished Stainless Steel Tubes

What inner surface roughness can DLSS guarantee?

For EP tubing we typically verify Ra ≤ 0.20 μm (inner) via profilometer; tighter ranges (≈0.13–0.18 μm) are available for select sizes.

Which industries should always choose EP over BA?

Pharmaceutical, biotech, semiconductor, and any system requiring validated cleaning (CIP/SIP) and low microbial adhesion.

Can DLSS provide TPI and full traceability?

Yes. We work with DNV, BV, LR, CCS and provide mill test certificates, Ra test records, and heat/batch traceability.