As the world searches for low-carbon, reliable energy, nuclear power is regaining momentum—this time with smaller, safer, and more modular technology.

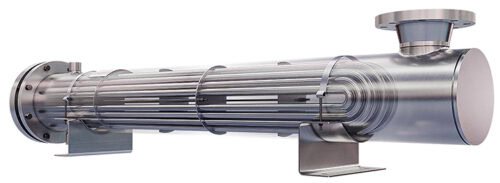

Small Modular Reactors (SMRs) are expected to play a vital role in off-grid energy, decarbonization of industry, and stable base-load supply. These reactors rely heavily on high-performance stainless steel and alloy tubing for their cooling systems, heat exchangers, condensers, and steam generators.

1. What Are SMRs, and Why Do They Matter?

- SMRs are nuclear reactors with an output typically under 300 MWe

- Designed for modularity, quicker deployment, and remote operation

- Used in military bases, mining regions, desalination, and industrial zones

- Targeted by over 20 countries for rollout between 2025–2040

Reference: International Atomic Energy Agency (IAEA) SMR Platform

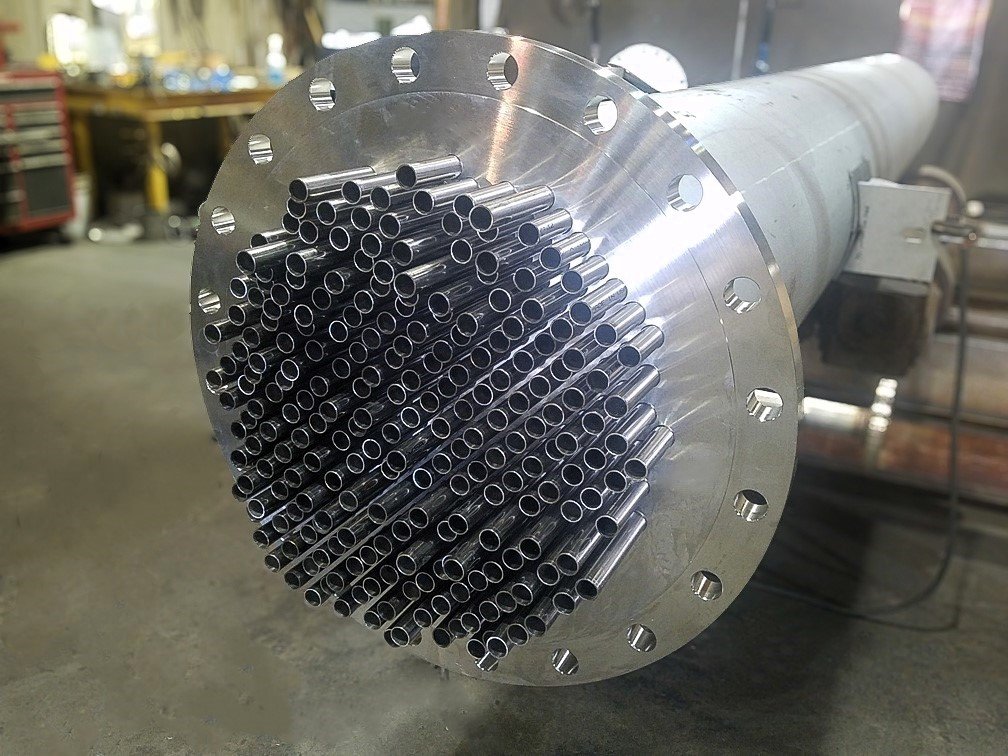

2. What Types of Tubes Are Needed in SMR Systems?

| Application | Tube Requirement |

|---|---|

| Primary heat exchangers | TP347H / TP316Ti with high-temperature stability |

| Steam generators | SA213 Class I tubing with wall thickness control |

| Pressurizers & recirculation loops | High-pressure seamless tubes, low sulfur, low carbon |

| Containment cooling | Corrosion-resistant tubes, bright annealed finish |

| Turbine condensers | U-bent or finned TP304L/316L coils |

Tubes used in nuclear systems must meet stringent ASME, RCC-M, or JSME codes, often requiring Level 1 or Level 2 safety class certifications, full NDE, and traceability from raw material to finished product.

3. Global SMR Projects Under Development

| Country | Project | Stainless Steel Opportunities |

|---|---|---|

| USA | NuScale, GE-Hitachi BWRX-300 | ASME Class I pipe, SA213 TP347H |

| Canada | Ontario Power Generation SMR | Nuclear-certified U-tubes |

| China | ACP100, HTR-PM | TP316Ti, 347H bright-annealed piping |

| France | EDF NUWARD SMR | EN + RCC-M qualified alloy pipes |

| South Korea | SMART reactor | Thin-wall corrosion-resistant bundles |

These projects favor manufacturers with nuclear-quality documentation, stable delivery cycles, and international inspection experience.

4. What Makes a Tube Supplier Nuclear-Ready?

- Certified to ASME NQA-1, ISO 19443, or relevant nuclear QA frameworks

- Provide full heat lot traceability, material test reports, and welding logs

- Conduct 100% UT, RT, and eddy current testing

- Support witnessed hydro and destructive testing

- Meet tight tolerance on wall thickness, concentricity, and surface finish

Suppliers like DLSS, while not yet supplying nuclear grade directly, can gradually build qualifications by supporting peripheral systems (non-safety-critical steam lines, condensers, cooling water).

Frequently Asked Questions (FAQ)

Q1: What’s the difference between TP316L and TP316Ti in nuclear service?

A: TP316Ti offers better resistance to sensitization at elevated temperatures, making it suitable for long-term use in systems above 500°C.

Q2: Can Chinese tube suppliers enter the SMR market?

A: Yes, especially in auxiliary systems or by partnering with certified EPCs. Achieving ASME N-type or ISO 19443 certification is key for direct nuclear component supply.

Q3: What testing is required for nuclear-grade stainless steel tubes?

A: Non-destructive testing (UT, ET, RT), mechanical tests (tensile, flattening, flaring), corrosion tests, and full documentation audit trails.

Q4: What packaging is used for nuclear tubes?

A: Individual tube capping, color-coding, alloy tagging, VCI paper wrapping, and crate labeling with P.O., batch, and heat number.

Conclusion: SMRs Need Smart Tubes

The global shift toward SMRs and modern nuclear systems is opening new high-specification, high-value markets for stainless steel tube manufacturers.

For suppliers that can meet the challenge—through tight dimensional control, total material traceability, and nuclear-ready documentation—the opportunity is long-term and strategic.

The reactors of the future are small—but the demand for precision tubes has never been bigger.