Meta Description:

Discover how stainless steel tubes support thermal efficiency, corrosion resistance, and long-term reliability in South American power generation plants.

Introduction

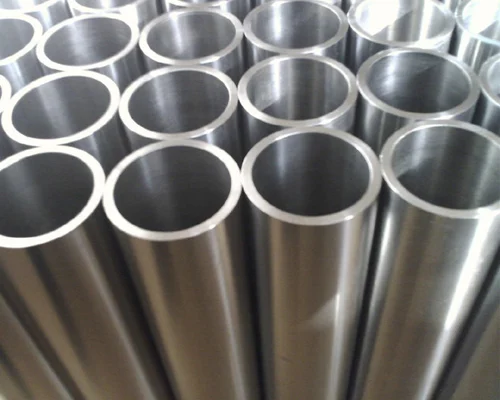

South America’s growing energy demand is driving the expansion of both conventional and renewable power plants. Whether it’s a thermoelectric station in Brazil or a biomass facility in Chile, one common requirement persists: reliable, long-lasting piping systems.

Stainless steel seamless tubes are essential in these operations, especially in heat recovery systems, boiler circuits, and high-pressure steam lines, where temperature, pressure, and corrosion resistance are critical.

Key Challenges in Power Plant Piping

Power plants in South America face:

- Chloride-rich environments (especially in coastal regions like Valparaíso or Recife)

- Thermal cycling and pressure surges

- Need for low-maintenance, long-life materials

- Regulatory compliance with international codes (ASME, EN, NBR)

To meet these demands, stainless steel seamless pipes provide a perfect balance between mechanical strength, thermal conductivity, and chemical stability.

Recommended Grades for Power Plant Applications

| Grade | Key Properties | Standards | Applications |

|---|---|---|---|

| TP316L | Corrosion resistance, weldability | ASTM A312 / A213, EN 10216-5 | Water feed lines, condensate systems |

| TP304H | High-temperature strength | ASTM A213, ASME SA213 | Superheaters, reheaters |

| TP347H/TP321H | Stabilized against intergranular corrosion | ASTM A213, EN 10216-5 | High-temperature steam pipelines |

| TP317L | Enhanced pitting resistance for coastal plants | ASTM A312, ASME B36.10 | Economizers, cooling loops |

| TP310S | Excellent resistance to oxidation at elevated temps | ASTM A213 | Furnace piping, heat recovery units |

Related resource: ASME Boiler & Pressure Vessel Code

DLSS Capabilities for the Power Sector

At DLSS, we deliver tailored solutions for South American EPC contractors and power plant operators:

- Pipe Sizes: 12.7 mm to 114.3 mm (OD), WT 0.8 mm – 8 mm

- Standards: ASTM A213, A312, EN 10216-5, ISO 9001

- Finishes: Pickled, Bright Annealed, Solution Annealed

- Tests Offered: PMI, UT, Eddy Current, Hydro Test, Hardness, Impact

- Documentation: EN 10204 3.1/3.2, NACE MR0175, Third-Party Witnessing

- Delivery: Containerized shipments to Brazil, Chile, Argentina, and Colombia

Learn more: Nickel Institute – High-Temperature Alloys in Power Plants

Recent Case Study – Brazil Thermoelectric Plant

In 2024, DLSS supplied over 18 tons of TP347H tubes to a thermoelectric project in Brazil. The tubes were used in the high-pressure steam lines and passed all hydro and UT tests under EN 10204 3.2 inspection with Bureau Veritas.

FAQs

Q: Are your stainless steel tubes suitable for high-pressure boilers?

Yes, DLSS offers certified tubes meeting ASME SA213 and EN 10216-5 requirements for boiler-grade tubing.

Q: Can you provide material traceability and documentation?

Absolutely. All tubes come with 3.1 or 3.2 MTCs, plus full heat traceability and optional TPI witness.

Q: Do you ship directly to South America?

Yes, we export to ports in Santos, Valparaíso, Buenos Aires, and more.

Conclusion

Power generation in South America relies on materials that perform under pressure—literally. DLSS stainless steel seamless tubes support safe, efficient, and long-lasting operations in critical piping systems. Our expertise, certifications, and proven track record make us a trusted partner for your next energy project.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com