Meta Description:

Learn the differences between seamless and welded stainless steel tubes, including performance, cost, applications, and when to choose each for your project.

Introduction

When specifying stainless steel tubing, one of the first decisions to make is:

Should you choose seamless or welded?

This choice affects not only performance and reliability but also cost, availability, and compliance with various industry standards.

This article will guide you through a clear comparison to help you make the right decision.

1. What Are Seamless Tubes?

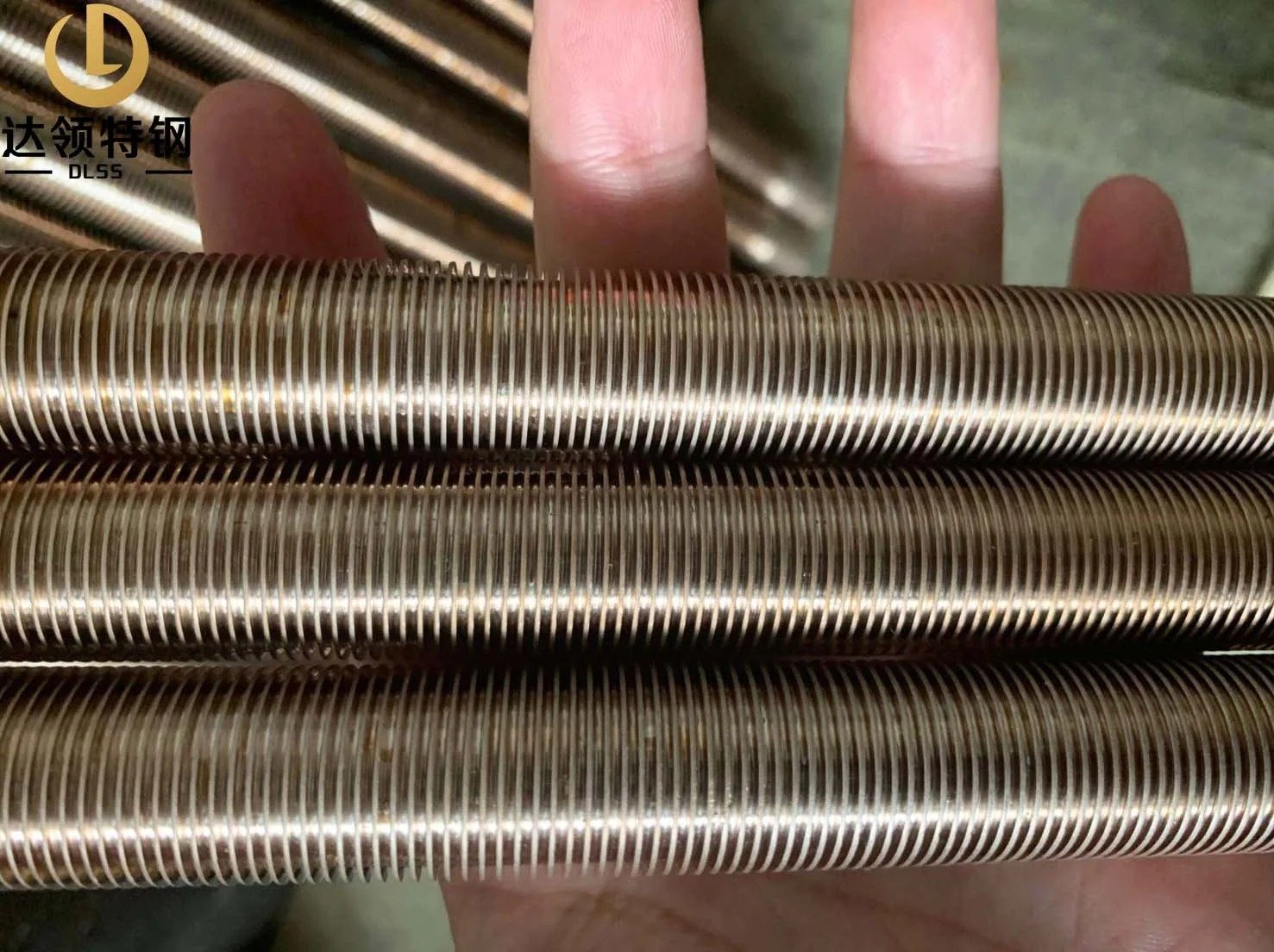

Seamless stainless steel tubes are made by extruding or piercing a solid billet, then elongating and sizing it through several hot or cold drawing processes.

Key Features:

- No weld seam → uniform strength

- Excellent pressure and corrosion resistance

- Typically used for critical applications

- Generally more expensive than welded

Standards:

- ASTM A213, A269, A312 (Seamless)

- EN 10216-5 (TC1 & TC2)

2. What Are Welded Tubes?

Welded stainless steel tubes are formed by rolling a strip of stainless steel and welding the seam using TIG, laser, or HF methods. The weld is then usually heat-treated and tested.

Key Features:

- Cost-effective and widely available

- Controlled tolerances and large size range

- Slightly lower pressure rating (due to seam)

- Weld bead may affect interior surface in some cases

Standards:

- ASTM A269, A312 (Welded)

- EN 10217-7

3. Seamless vs Welded – Comparison Table

| Attribute | Seamless Tubes | Welded Tubes |

|---|---|---|

| Weld Seam | None | Present (welded and heat-treated) |

| Pressure Rating | Higher | Slightly lower |

| Corrosion Resistance | Excellent (no weld defects) | Excellent (if properly processed) |

| Surface Finish | Can be BA or EP | BA, pickled, polished options |

| Tolerance | Moderate | Tighter and more consistent |

| Cost | Higher | More economical |

| Availability (sizes) | Limited in large OD | Wide range available |

| Application | High-pressure, high-purity | Structural, general process use |

4. Application-Based Recommendation

| Application | Recommended Tube Type |

|---|---|

| Heat Exchangers, Boilers | Seamless (ASTM A213) |

| Instrumentation / Hydraulic Lines | Seamless (ASTM A269) |

| Structural / Decorative Piping | Welded |

| Chemical / Petrochemical Processing | Seamless or Welded |

| Water Treatment / Plumbing | Welded |

| Food & Beverage Transfer Lines | Welded (BA or EP) |

| Ultra-Clean Pharmaceutical Use | Seamless EP |

Learn more from ASTM A312 vs EN 10216-5 Comparison

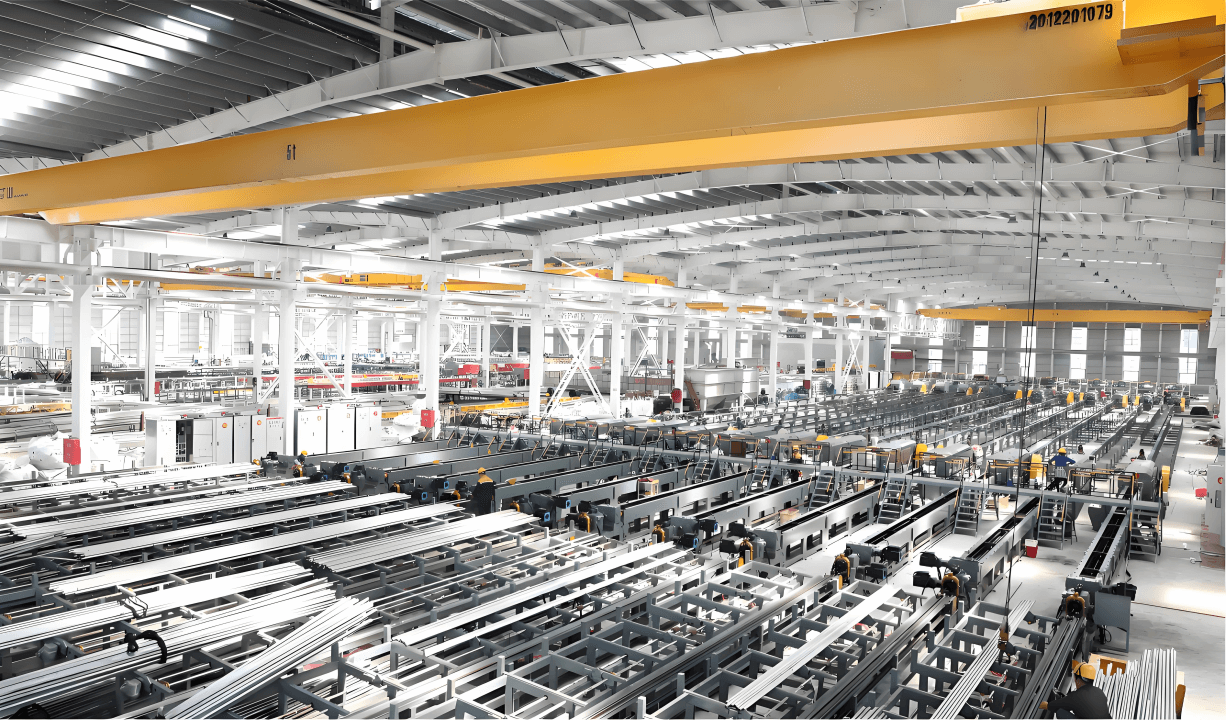

5. DLSS Capabilities

DLSS manufactures and exports both seamless and welded tubes based on:

- Grades: TP304, TP316L, TP321, Duplex 2205, 2507, 904L, Incoloy 825

- OD Range: 6 mm to 219 mm

- Wall Thickness: 0.5 mm to 10 mm

- Finish Options: BA, Pickled, EP, Polished

- Testing: Hydro, UT, ET, PMI, Surface Ra

- Certifications: EN 10204 3.1 / 3.2, NACE MR0175, ISO 15156

FAQs

Q1: Is the seam in welded tubes a weak point?

Not necessarily. When welded properly and heat-treated, the seam is metallurgically sound and can perform comparably to seamless in many applications.

Q2: Are seamless tubes always better?

No. They’re better for high-pressure or critical applications, but welded tubes are more cost-effective and sufficient for many uses.

Q3: Can DLSS provide EP on welded tubes?

Yes. DLSS offers electropolishing services for both seamless and welded tubes.

Q4: Which tube type is easier to source in custom lengths?

Welded tubes. They can be produced more flexibly with tight tolerances and at longer lengths.

Conclusion

Choosing between seamless and welded stainless steel tubes depends on your specific requirements—including pressure, cleanliness, budget, and certification needs. DLSS provides both types with global standards, full traceability, and custom finishes to suit your project.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Not sure which tube type fits your application best? DLSS engineers are ready to provide technical recommendations and help you reduce cost without compromising performance.