Introduction

Nickel 200 seamless tubes and Nickel 201 seamless tubes are widely used in industries requiring high-purity, corrosion-resistant, and thermally conductive materials. These nickel alloy seamless pipes offer exceptional performance in chemical processing, caustic environments, cryogenic systems, and electrolytic applications.

According to Wikipedia, both Nickel 200 and 201 belong to the category of commercially pure wrought nickel with at least 99.6% Ni content.

What Are Nickel 200 and Nickel 201 Seamless Tubes?

Nickel 200 seamless pipe and Nickel 201 seamless pipe are hot-extruded or cold-drawn nickel alloy seamless tubes designed for critical pressure systems. The major difference lies in their carbon content:

| Grade | Nickel Content | Carbon Content | Max Operating Temp |

|---|---|---|---|

| Nickel 200 | ≥ 99.6% | ≤ 0.15% | ~315°C |

| Nickel 201 | ≥ 99.6% | ≤ 0.02% | ~649°C |

Because of its low carbon content, Nickel 201 tubing resists graphitization and is preferred in high-temperature alkali processes.

Mechanical and Physical Properties

| Property | Nickel 200 | Nickel 201 |

|---|---|---|

| Tensile Strength (MPa) | ≥ 340 | ≥ 345 |

| Yield Strength (MPa) | ≥ 105 | ≥ 103 |

| Elongation (%) | ≥ 40 | ≥ 45 |

| Thermal Conductivity | ~90 W/m·K | ~90 W/m·K |

| Electrical Resistivity | 0.100 μΩ·m | 0.094 μΩ·m |

Reference: ASTM B161 Standard

These properties make them ideal for seamless nickel pipe used in high-purity processing systems and cryogenic nickel tubes.

Key Advantages

- Excellent resistance to caustic soda, alkali chlorides, and fluorides

- Suitable for cryogenic tubing due to ductility at -196°C

- Non-magnetic, easy to form and weld

- High electrical and thermal conductivity, ideal for battery-grade nickel tubing

- Fully compliant with ASTM B161 nickel tubing standards

Keywords embedded: Nickel 200 seamless tube, Nickel 201 seamless tube, nickel alloy pipe for caustic service, cryogenic nickel tubing, battery-grade nickel pipe, ASTM B161 seamless pipe

Typical Applications

- Caustic soda plants

- Salt production equipment

- Battery manufacturing (nickel anodes)

- Synthetic fiber production equipment

- LNG storage and cryogenic distribution lines

- Pharmaceutical and food-grade piping systems

- Electronic shielding tubes

Learn more: Sodium hydroxide – Wikipedia

Manufacturing Standards

- ASTM B161 – Standard Specification for Nickel 200/201 Seamless Pipe

- ASME SB-161 – Pressure vessel equivalent

- ISO / DIN available upon request

- Inspection: PMI, Hydrotest, Ultrasonic

- Certifications: EN10204 3.1, SGS, TÜV, BV

Keyword focus: Nickel 200 pipe manufacturer, Nickel 201 tube exporter, ASTM B161 seamless tube supplier

Nickel 200 vs. Nickel 201: Which Should You Choose?

| Application Condition | Recommended Grade |

|---|---|

| Below 300°C, general use | Nickel 200 |

| Above 300°C, graphitization risk | Nickel 201 |

| Deep drawing, cold forming | Nickel 201 |

| Cryogenic systems | Both suitable |

| High-purity chemical process | Nickel 200 / 201 |

DLSS engineers can help with nickel alloy grade selection based on your operating environment.

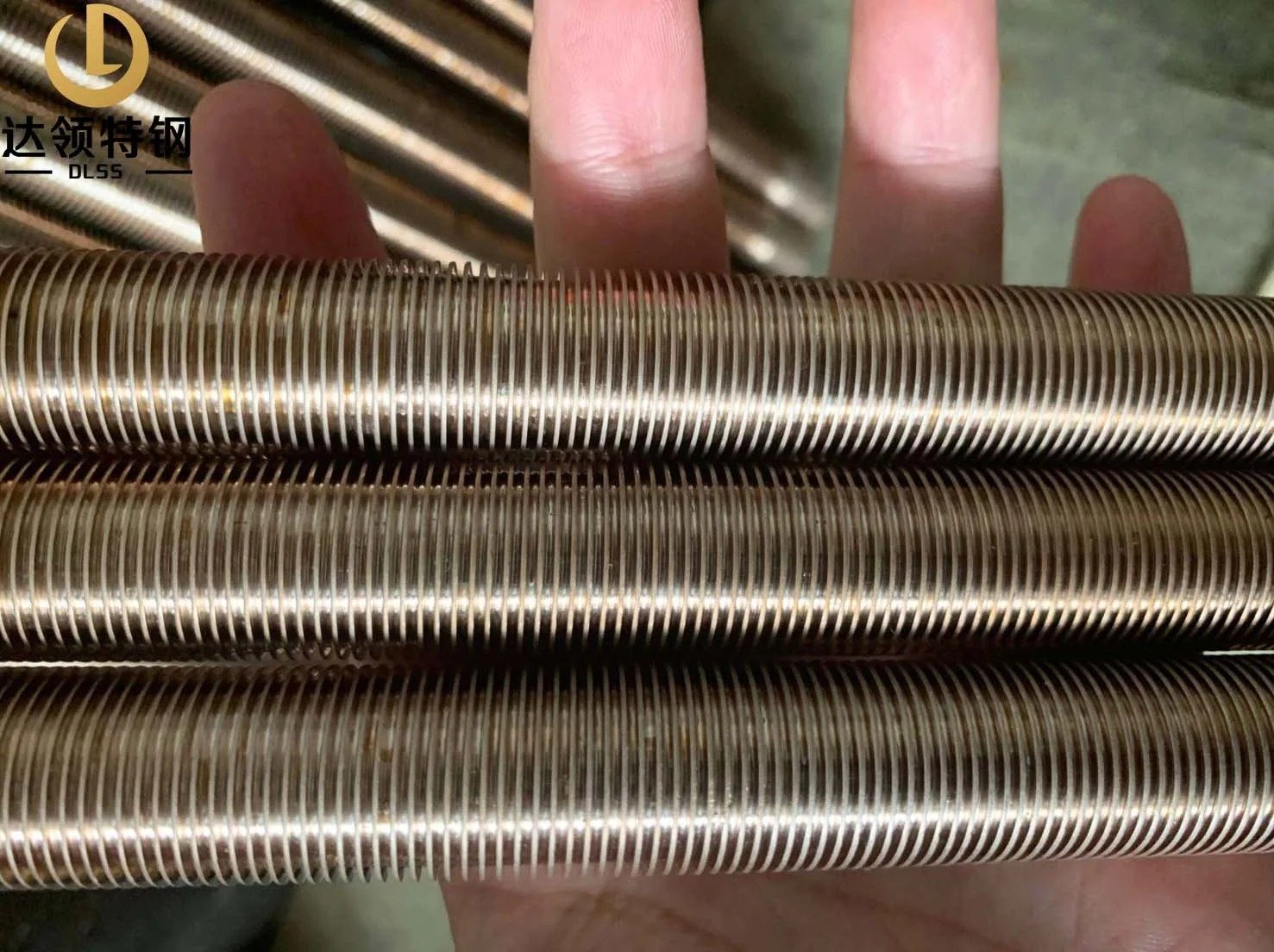

Why Choose DLSS Nickel Seamless Tubes?

DLSS manufactures and exports precision nickel alloy seamless tubes, focusing on Nickel 200 and 201 pipe applications in chemical, pharmaceutical, and cryogenic systems. We offer:

- Cold-drawn nickel tubing with tight tolerances

- U-bent, straight, and coiled nickel alloy pipe

- Rapid delivery, strict QC, and global shipping

- Seamless pipes from OD 6 mm to 60 mm

Visit: www.dlsspipe.com

Contact Us

DLSS is your trusted partner for Nickel 200 seamless tubes, Nickel 201 pipes, and other nickel alloy tubing solutions.

Email: info@dlsspipe.com

Website: www.dlsspipe.com

FAQ

Q1: Can Nickel 200/201 be used in marine environments?

They offer some seawater resistance but are not ideal for high-chloride exposure. Consider Monel 400 for marine use.

Q2: Are these grades suitable for sanitary tubing?

Yes, especially for food processing nickel tubing and pharmaceutical-grade applications.

Q3: What surface condition is available?

Annealed, bright-annealed, or pickled. Special polishing available on request.