Introduction

Nickel alloy steel seamless pipes and tubes are essential materials in demanding industries where components must withstand extreme temperatures, corrosive chemicals, and high pressure. Their seamless structure combined with the superior characteristics of nickel-based alloys makes them the material of choice for chemical processing, petrochemical, marine, power generation, and LNG applications.

Nickel-based alloys are highly engineered materials. They offer remarkable performance due to their high nickel content, often combined with chromium, molybdenum, cobalt, and iron, giving them resistance to oxidation, pitting, and stress-corrosion cracking.

Learn more: Nickel alloy – Wikipedia

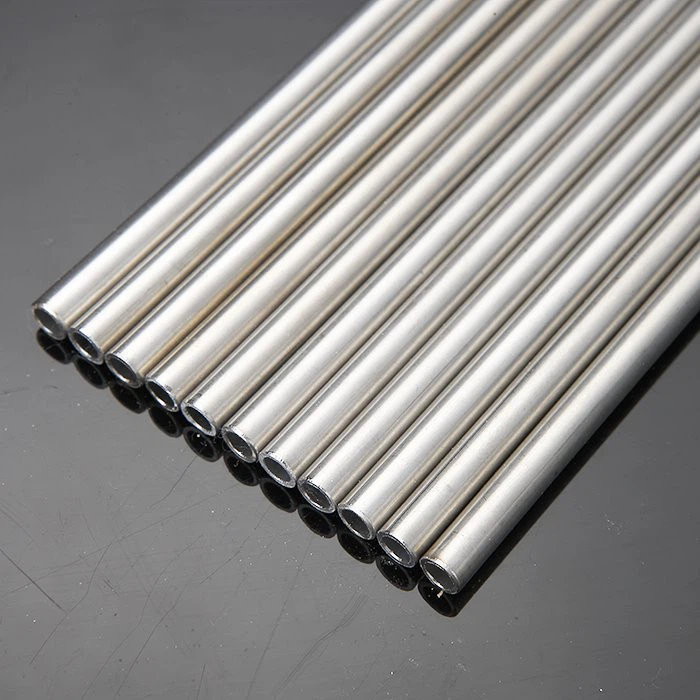

What Are Nickel Alloy Seamless Pipes?

Nickel alloy seamless pipes and tubes are cylindrical products made from fully austenitic, corrosion-resistant alloys such as:

- Nickel 200 / Nickel 201

- Inconel (e.g., 600, 625, 718)

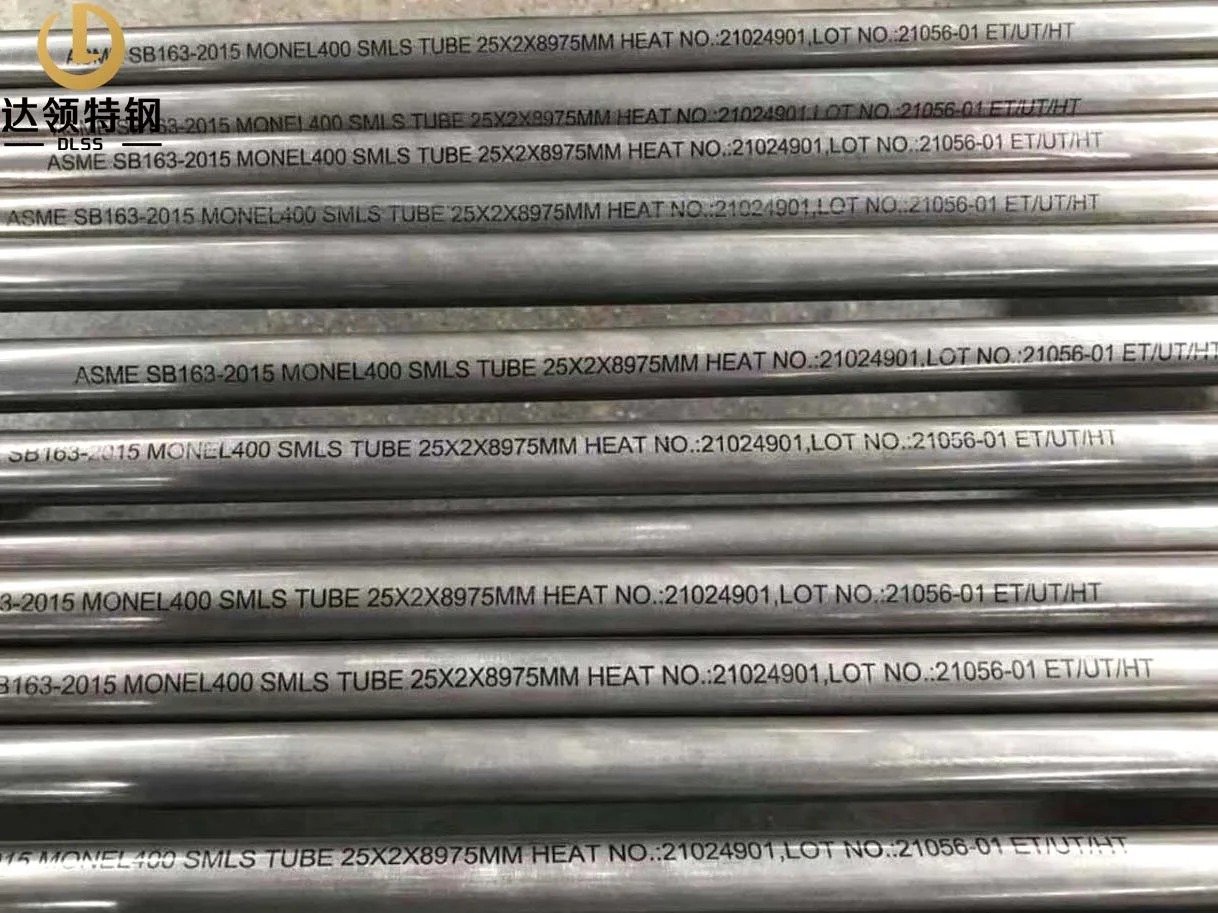

- Monel (e.g., 400, K500)

- Hastelloy (e.g., C-22, C-276)

- Incoloy (e.g., 800H, 825)

These materials deliver exceptional performance in chloride-bearing environments, acidic process fluids, and high-temperature atmospheres.

Learn more:

Manufacturing Process

Nickel alloy seamless tubes are produced using a strict multi-step process to ensure dimensional accuracy, mechanical integrity, and defect-free surfaces:

- Hot extrusion or rotary piercing of nickel alloy billets

- Cold pilgering or drawing to refine dimensions

- Solution annealing and heat treatment for corrosion resistance and mechanical properties

- Pickling or polishing for a clean internal/external surface

- Non-destructive testing (NDT) such as ultrasonic and eddy current tests

Industrial Applications

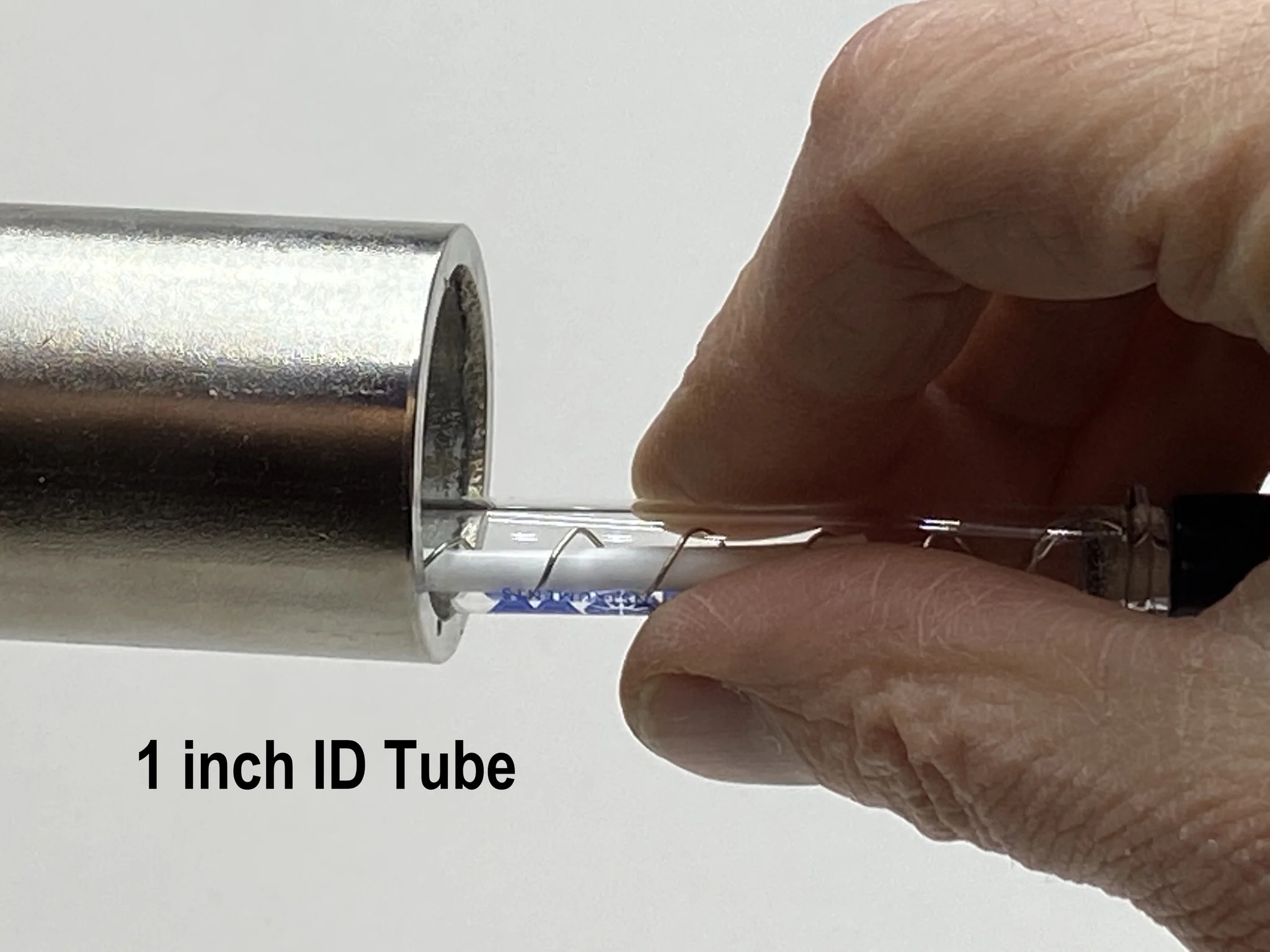

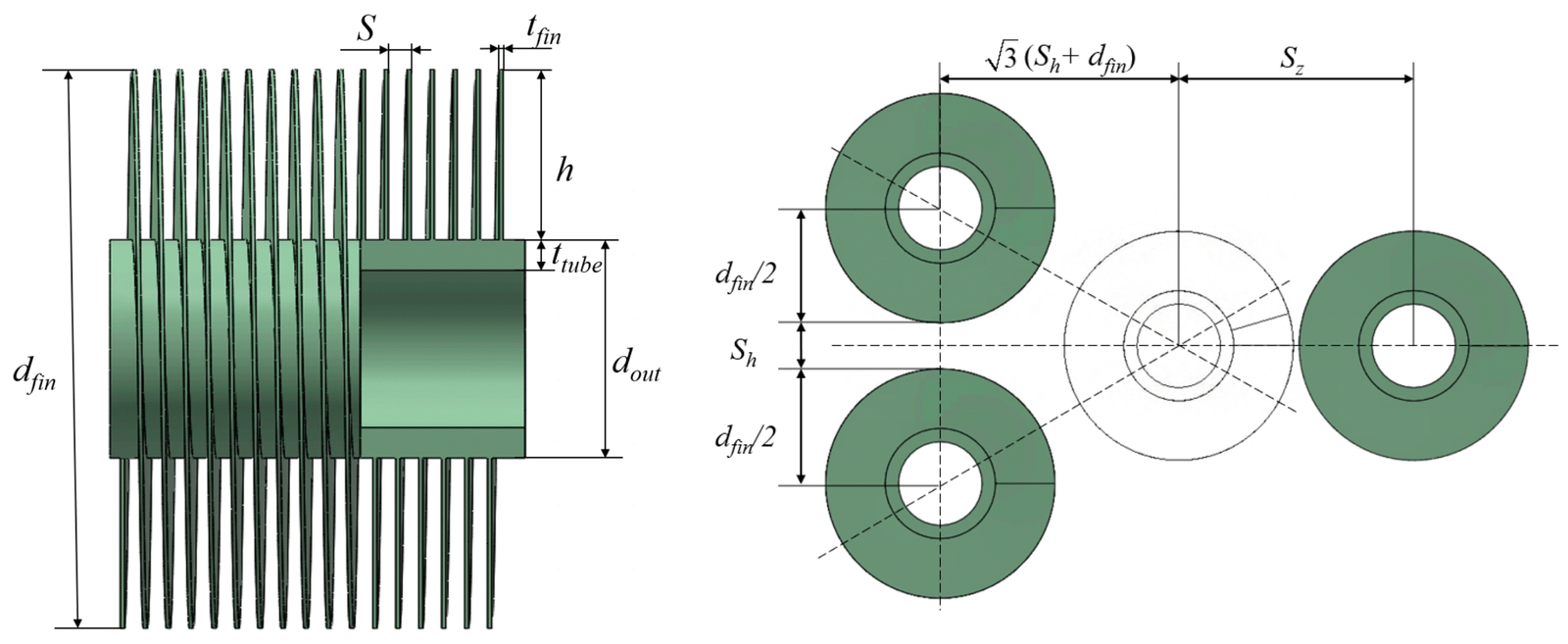

Heat Exchangers and Condensers

Nickel alloy tubes are used extensively in shell and tube heat exchangers, especially in systems involving acidic, chlorinated, or high-salinity media. Inconel 625 and Hastelloy C-276 are the most common grades used.

Read more: Heat exchanger – Wikipedia

Oil & Gas and Offshore

In offshore oil production, pipelines and tubing systems require resistance to seawater, hydrogen sulfide (H₂S), and CO₂. Nickel alloys like Monel 400 and Incoloy 825 are widely used in sour service.

LNG and Cryogenic Systems

Nickel alloys retain toughness and ductility at very low temperatures. For cryogenic and LNG systems, Nickel 201 and Inconel 600 are ideal choices for liquefaction lines, vaporizers, and storage tank heat exchangers.

Explore more: Liquefied natural gas – Wikipedia

Power Generation

In nuclear and thermal power plants, Incoloy 800H and Inconel 600 seamless pipes are used in superheaters, boiler feedwater systems, and reheaters due to their long-term creep resistance and oxidation resistance.

Key Advantages

| Feature | Technical Benefit |

|---|---|

| Seamless Construction | Eliminates weld failures and ensures leak-tight integrity |

| High Nickel Content | Excellent resistance to acidic, caustic, and saline media |

| Temperature Stability | Operates at temperatures >600°C and below –196°C |

| Mechanical Strength | High yield and tensile strength in high-pressure systems |

| Long Service Life | Reduces replacement frequency and maintenance costs |

| Weldability and Machinability | Compatible with various fabrication methods |

Applicable Industry Standards

Nickel alloy seamless tubes are manufactured in compliance with:

- ASTM B161 – Seamless Nickel 200/201 Pipes

- ASTM B167 – Seamless Inconel 600, 601, 625 Tubes

- ASTM B444 – Seamless Inconel 625 Tubing

- ASTM B423 – Seamless Incoloy 825 Tubes

- ASME Section II – Material specifications

- ISO 6207 – Wikipedia – Seamless tubes for heat exchangers

Market Insights and Trends

According to MarketsandMarkets, the nickel alloy market is projected to reach USD 18.7 billion by 2030, growing at a CAGR of 7.5%, driven by:

- The expansion of LNG infrastructure

- Increased use of desalination plants

- Clean energy and green hydrogen projects

- Replacement of aging refinery and offshore infrastructure

FAQs

Q1: Are nickel alloy seamless pipes better than stainless steel?

A: Yes. They offer higher corrosion resistance, especially in chloride-rich or acidic environments.

Q2: Which industries use nickel alloy tubes the most?

A: Oil & gas, chemical processing, power generation, desalination, marine, and LNG.

Q3: What is the difference between Nickel 200 and 201?

A: Nickel 201 has lower carbon content, offering better resistance to graphitization at high temperatures.

More info: Nickel 200 and 201 – Wikipedia

Contact DLSS – Your Trusted Alloy Tube Partner

DLSS is a global supplier of nickel alloy seamless pipes and tubes, serving clients in over 40 countries. We provide:

- Inconel, Monel, Hastelloy, Incoloy seamless pipes

- U-bent and finned tubes for heat exchangers

- Custom sizes and third-party inspection (SGS, TUV, BV)

Email: info@dlsspipe.com

Website: www.dlsspipe.com

We deliver precision + performance—engineered to meet your most demanding specifications.