Meta Description:

Explore the key differences between nickel alloy tubes and stainless steel tubes. Understand when to select Inconel, Monel, or Hastelloy instead of TP316 or Duplex 2205, and how to evaluate performance vs. cost in demanding applications.

Introduction

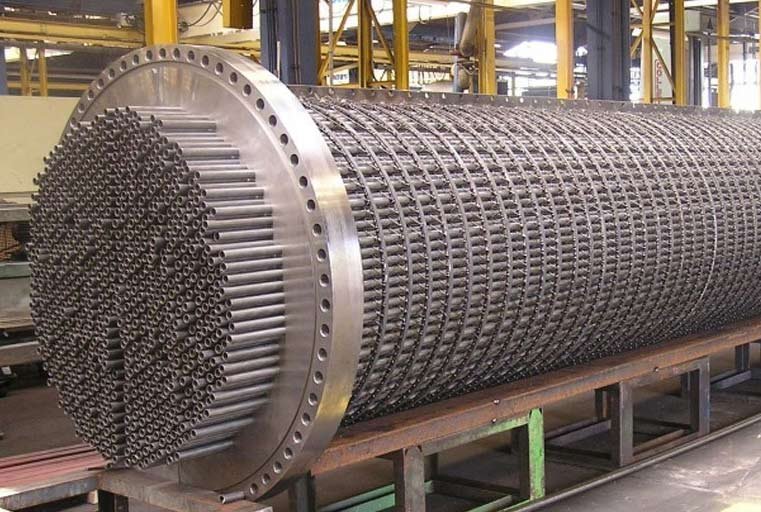

In critical industries like oil & gas, chemical processing, power generation, and aerospace, choosing between stainless steel tubes and nickel alloy tubes can be the deciding factor in system reliability and longevity.

This article explains the differences in composition, corrosion resistance, heat resistance, and cost between these two families of materials, helping you make the best choice for your project needs.

1. What Are Nickel Alloys?

Nickel alloys are high-performance materials with nickel content typically above 30%, often alloyed with chromium, molybdenum, iron, or copper. They are engineered for extreme environments, where stainless steels may fall short.

Common Nickel Alloys Used in Tubes:

| Alloy | UNS Number | Key Standards | Main Attributes |

|---|---|---|---|

| Inconel 600 | N06600 | ASTM B167, B163 | High-temp oxidation and chloride resistance |

| Inconel 625 | N06625 | ASTM B444 | Excellent fatigue, chloride, and acid resistance |

| Incoloy 825 | N08825 | ASTM B163, B423 | Resistant to sulfuric and phosphoric acids |

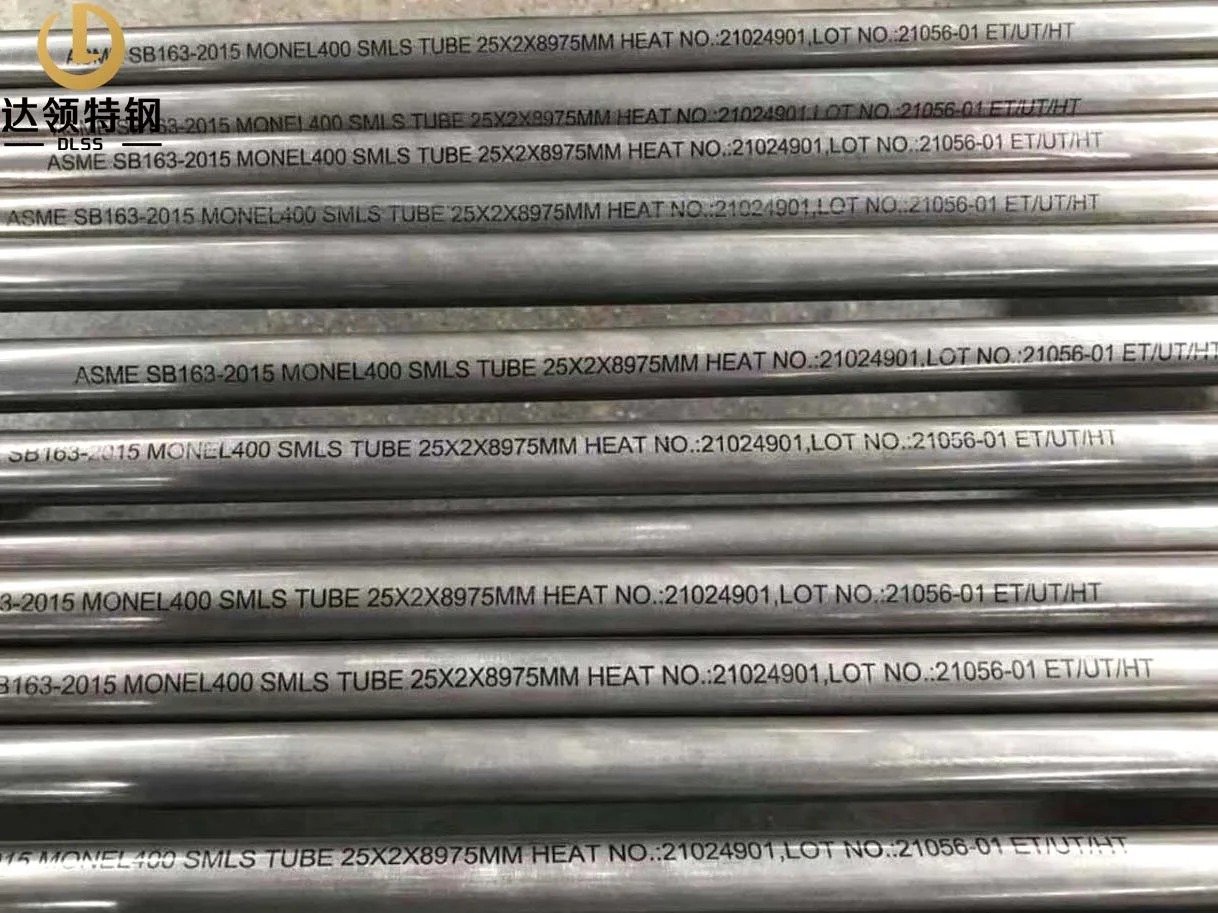

| Monel 400 | N04400 | ASTM B165 | Outstanding in seawater, non-oxidizing acids |

| Hastelloy C-276 | N10276 | ASTM B622, B619 | Extreme corrosion resistance in mixed acids |

2. Stainless Steel vs. Nickel Alloys – Side-by-Side Comparison

| Property | Stainless Steel (TP316, 2205) | Nickel Alloys (Inconel, Monel, Hastelloy) |

|---|---|---|

| Nickel Content (%) | 8–22 | 30–70+ |

| Corrosion Resistance | Excellent in mild to moderate | Exceptional in severe acids, chlorides |

| Pitting/Crevice Resistance | Good (with Mo) | Outstanding |

| Max Operating Temperature | ~800°C (TP310, 321) | >1100°C (Inconel 625, 600) |

| Cost | Moderate | High |

| Weldability | Easy (except Duplex) | Requires expertise |

| Common Standards | ASTM A213, A269, EN 10216-5 | ASTM B163, B167, B444, B622 |

Reference: Nickel Institute – Nickel Alloys Overview

3. When to Choose Nickel Alloys Over Stainless Steel

A. Extreme Chemical Environments

- Sulfuric, hydrochloric, and phosphoric acid exposure → Incoloy 825, Hastelloy C-276

- Mixed acids, high chloride + temperature → Inconel 625 or C-22

B. High Temperature + High Pressure

- Power plant boiler tubes, aerospace, nuclear → Inconel 600, 625

- Nickel alloys maintain structural integrity above 1000°C

C. Seawater or Brine Resistance

- Monel 400 performs better than 316L or Duplex 2205 in stagnant seawater or acidic saline water

D. Hydrogen Sulfide (H₂S) Environments

- Oil & gas sour service → Alloy 825 or Hastelloy under NACE MR0175

For compliance data:

NACE MR0175 Material Selection

4. Cost Consideration

While nickel alloys cost significantly more than stainless steel per ton, their extended service life, reduced maintenance, and failure avoidance in critical systems make them more economical over time in harsh service.

Stainless steel remains more cost-effective in general service, food-grade, and non-aggressive environments.

5. DLSS Capabilities for Nickel Alloy Tubes

DLSS offers precision-manufactured tubes in:

- Inconel 600 / 625, Incoloy 825, Monel 400, Hastelloy C-276

- Sizes: 6 mm – 60 mm OD, wall thickness 0.5 – 5 mm

- Standards: ASTM B163, B444, B622, NACE MR0175

- Surface: Bright annealed, pickled, and polished

- Tests: PMI, UT, ET, Hydro, Intergranular Corrosion (IGC)

All materials include full MTC 3.1/3.2, traceability, and documentation support.

FAQs

Q1: Can I use TP316L in place of Incoloy 825 in phosphoric acid?

No, Incoloy 825 offers far better corrosion resistance in strong acidic media.

Q2: Is welding nickel alloys difficult?

Yes, but DLSS provides recommended procedures and filler materials. TIG welding with inert gas shielding is essential.

Q3: Do you provide third-party inspection for nickel alloy tubes?

Yes, DLSS supports SGS, BV, TÜV, and customer-nominated inspections.

Q4: Are these tubes available from stock?

Nickel alloys are mostly custom-produced to order due to cost and specification diversity.

Conclusion

Nickel alloys provide unmatched performance in harsh environments where stainless steel may fall short. Choosing the right material ensures safety, efficiency, and regulatory compliance. DLSS helps clients evaluate material options based on real operating conditions, delivering tailored solutions with full traceability and support.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Looking for nickel alloy tubes for chemical plants, offshore rigs, or power generation? DLSS delivers globally with certified quality and fast response.