Meta Description:

Learn the key differences between seamless and welded stainless steel pipes. Discover which option is better for pressure, corrosion, and project reliability in modern industrial applications.

Introduction

When selecting stainless steel pipes for high-stakes projects—whether in oil & gas, chemical processing, or heat exchanger systems—one key decision is:

Should I choose seamless or welded pipe?

With evolving quality standards and application-specific demands, this comparison remains a hot topic in 2025.

In this article, we explore the structural, operational, and cost-related differences between the two and help you decide which is right for your system.

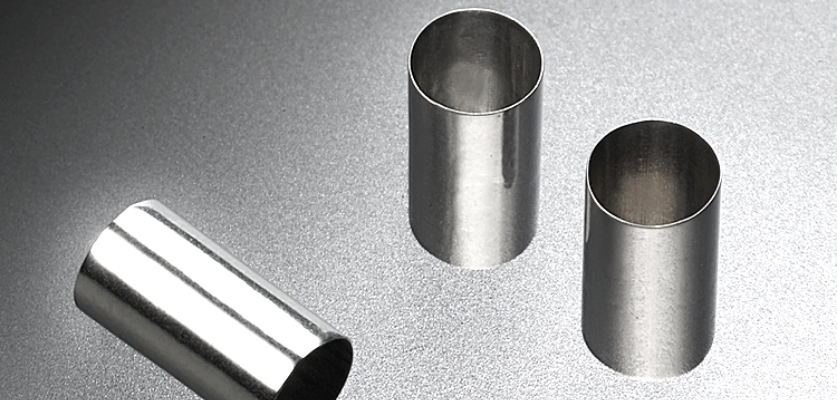

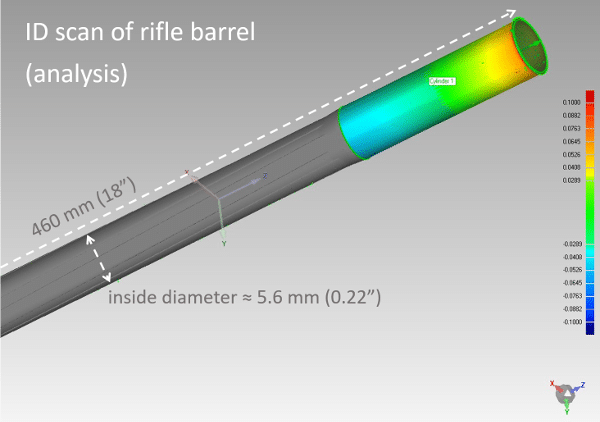

What Are Seamless Pipes?

Seamless pipes are manufactured from a solid billet through hot extrusion or piercing, resulting in:

- No weld seam

- Uniform mechanical properties

- Excellent pressure and temperature resistance

They are widely used in:

- High-pressure boilers

- Refineries and offshore rigs

- Heat exchangers with U-bends

- Critical sour gas applications

Standard: ASTM A213 – Seamless Stainless Tubes for Boilers and Heat Exchangers

What Are Welded Pipes?

Welded pipes are formed by rolling and welding stainless steel plates or strips, then heat treated and surface finished. They are:

- More economical

- Available in longer lengths and larger diameters

- Suitable for low- to medium-pressure applications

Typical use cases:

- Sanitary piping (food & beverage)

- Building infrastructure

- Non-critical utility lines

Standard: ASTM A269 – Welded or Seamless Tubes for General Service

Technical Comparison

| Attribute | Seamless Pipe | Welded Pipe |

|---|---|---|

| Weld seam | None | Yes (may be ground, annealed) |

| Pressure resistance | Higher | Lower (not suitable for severe cycles) |

| Corrosion resistance | Better (no weld zones) | Acceptable with proper welding and pickling |

| Dimensional control | Slightly lower | Tighter tolerances |

| Cost | Higher (10–30%) | Lower production cost |

| Inspection | EC / UT / Hydro required | Weld seam often requires X-ray or PT |

Market Trend in 2025

As per Future Market Insights, over 65% of stainless steel pipe projects above Class 300 are now using seamless tubes due to increased emphasis on:

- Lifecycle cost reduction

- Risk mitigation in harsh environments

- Standard compliance (NACE, EN 10204 3.2)

However, for cost-sensitive or sanitary systems, welded pipes still offer a reliable and hygienic option.

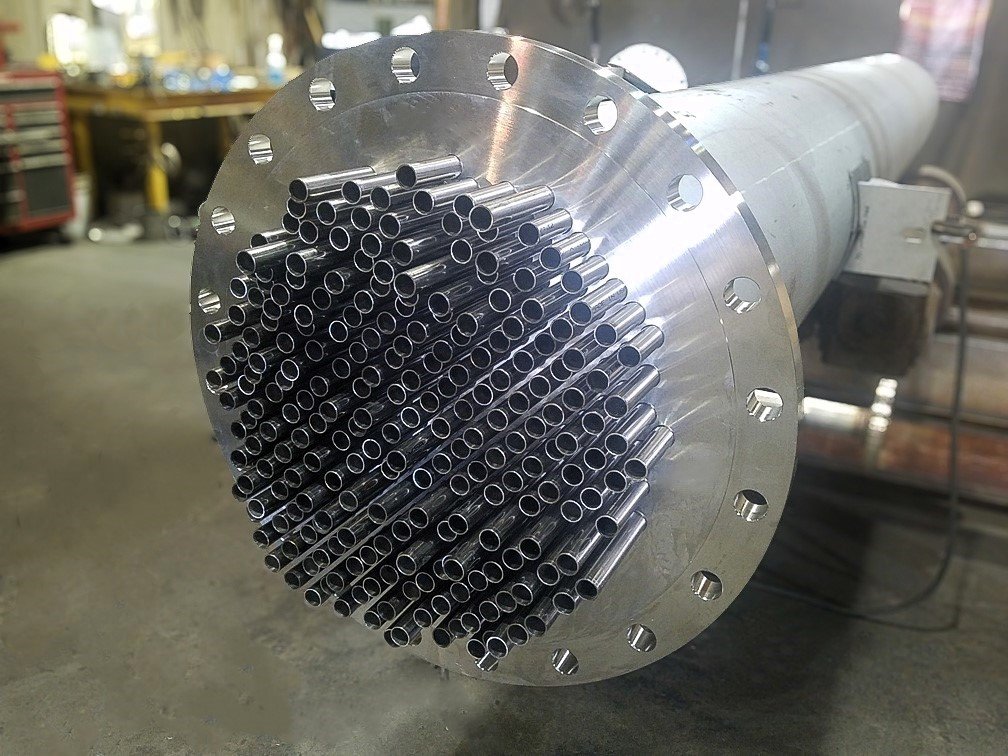

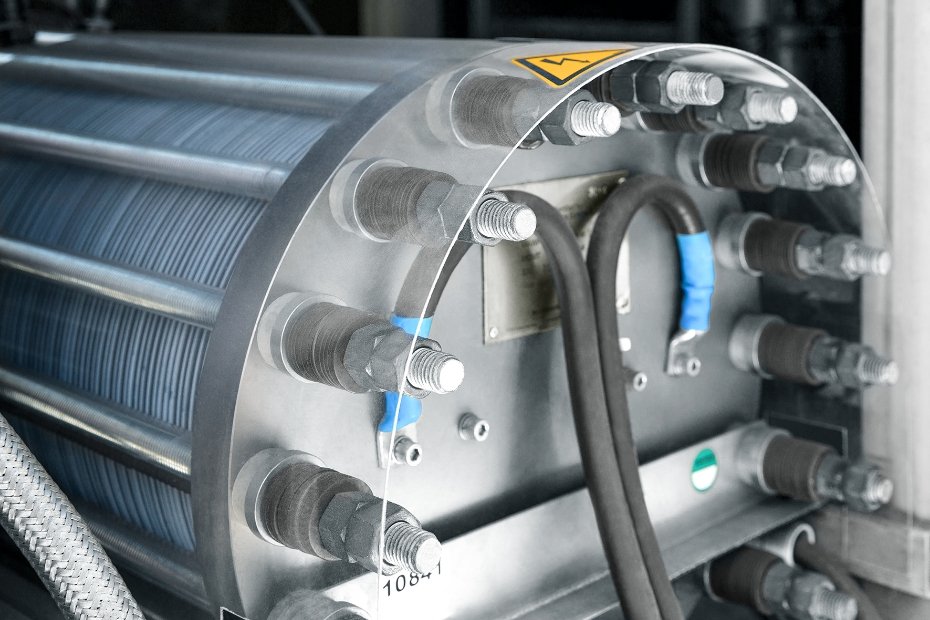

How DLSS Supports Both Solutions

DLSS manufactures and supplies both seamless and welded stainless pipes:

- Seamless: TP316L, TP321, TP347H, Duplex, Incoloy

- Welded: A269-grade sanitary and low-pressure tubes

- Surface finishes: Pickled, Bright Annealed, Electropolished

- Certifications: EN 10204 3.1 / 3.2, NACE MR0175, PMI, EC, Hydro

- Third-party inspections: SGS, TÜV, BV on request

Frequently Asked Questions (FAQ)

Q1: Is seamless always better than welded?

Not always. Seamless is stronger under pressure, but welded tubes offer good reliability in low-stress and clean-service systems.

Q2: Which is better for heat exchanger U-bends?

Seamless is preferred due to uniform wall thickness and flexibility under bending stress.

Q3: Do welded pipes always need X-ray testing?

Not always, but X-ray or PT is common in Class 300+ systems to ensure seam integrity.

Q4: What’s the cost difference?

Welded pipes are generally 10–30% cheaper, depending on OD, wall thickness, and finish.

Conclusion

The best pipe for your project depends on application requirements, regulatory standards, and long-term reliability goals.

Choose seamless when dealing with:

- High pressure or high temperature

- Fatigue or thermal cycling

- Critical corrosive fluids

Choose welded for:

- Low-pressure sanitary lines

- Architectural installations

- Budget-sensitive applications

DLSS supports both options with standard-compliant products, detailed testing, and custom fabrication to match your project’s demands.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com