Meta Description:

Explore how stainless steel seamless pipes tested to NACE MR0175 / ISO 15156 and MR0103 standards ensure safety in sour service environments. Learn about SSC, HIC, and corrosion resistance.

Introduction

Sour service environments—such as oil and gas fields containing hydrogen sulfide (H₂S)—pose serious challenges to piping materials. Without the proper metallurgy and testing, stainless steel pipes can fail due to sulfide stress cracking (SSC) or hydrogen-induced cracking (HIC).

To prevent such failures, international standards like NACE MR0175 / ISO 15156 and NACE MR0103 define the material and testing requirements for metallic components used in sour gas environments.

DLSS offers stainless steel seamless tubes that fully comply with these critical standards.

What Is NACE MR0175 / ISO 15156?

NACE MR0175 / ISO 15156 is a globally recognized standard published by the National Association of Corrosion Engineers (NACE). It outlines requirements for the selection and qualification of materials used in H₂S-containing oil and gas production environments.

Key features include:

- Guidelines for chemical composition and hardness limits

- Testing for SSC (Sulfide Stress Cracking)

- Requirements for microstructure and heat treatment control

What Is NACE MR0103?

NACE MR0103 applies to downstream refining equipment, defining similar criteria to prevent SSC and HIC in environments with wet H₂S—such as amine units and sour water systems.

It is often referenced in refineries, fertilizer plants, and gas processing facilities.

Why Stainless Steel Needs SSC / HIC Qualification

In sour service, high-strength or improperly heat-treated stainless steel is vulnerable to cracking when exposed to H₂S, particularly under tensile stress. Therefore, any stainless steel pipe used in these environments must:

- Have controlled hardness (<22 HRC for most grades)

- Exhibit homogeneous microstructure

- Pass SSC (per NACE TM0177) and HIC tests (per NACE TM0284)

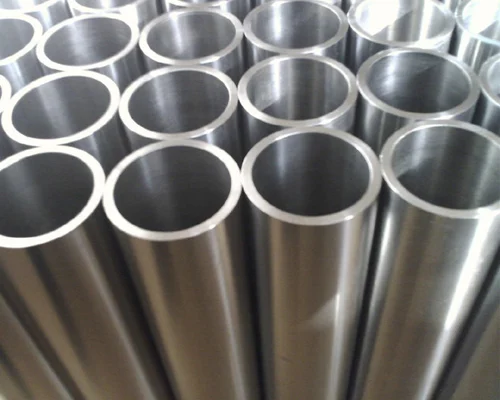

DLSS Stainless Steel Seamless Pipe for Sour Service

We offer stainless steel seamless pipes manufactured and tested according to:

- ASTM A312 / A213

- NACE MR0175 / ISO 15156

- NACE MR0103

- EN10204 3.1 / 3.2 Certification

Example Product:

- Material: Stainless Steel Seamless Pipe (TP316L / 317L / Duplex 2205)

- Outer Diameter: as per client spec (e.g. 19.05mm)

- Wall Thickness: as per design pressure

- Length: up to 12 meters

- Surface: Pickled, Annealed, or Bright Annealed

- Testing:

- 100% Eddy Current or UT

- SSC Test (NACE TM0177 Method A/B)

- HIC Test (NACE TM0284)

- Hardness ≤ 22 HRC (typically < 200 HB)

Material Grades for NACE Compliance

| Grade | Typical Use | Remarks |

|---|---|---|

| TP316L | General sour service | Low C, low hardness, good weldability |

| TP317L | High Mo for chloride-rich H₂S conditions | Enhanced pitting resistance |

| S31803 / S32205 | Duplex for stronger resistance & strength | Must control ferrite phase properly |

| Alloy 825 | Strong acid resistance (sulfuric, phosphoric) | Nickel alloy for severe sour service |

Common Applications

- Upstream oil & gas pipelines

- Natural gas dehydration units

- Sour water stripper systems

- Amine regeneration columns

- Refinery desulfurization piping

- Gas injection systems with wet H₂S

Documentation Provided by DLSS

- Material Test Certificate (EN10204 3.1/3.2)

- NACE SSC/HIC Test Report

- PMI and UT Inspection Report

- Heat Treatment Record

- Hardness Test (Brinell / Rockwell)

SEO Keywords

- Stainless steel pipe for NACE MR0175

- NACE MR0103 seamless tube supplier

- HIC tested stainless steel pipe

- sour service pipe for H2S

- SSC resistant pipe

- NACE-compliant stainless tubing

- TP316L MR0175 approved pipe

- duplex stainless steel for sour gas

- hydrogen sulfide cracking prevention

- ASTM A312 pipe for acid gas application

Contact DLSS for NACE-Approved Tubing

If you’re sourcing stainless steel seamless pipe for use in H₂S-containing systems, contact DLSS for:

- Grade selection

- SSC/HIC test reports

- Competitive pricing

- Fast delivery for critical applications

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Our pipes are trusted by engineering firms, EPCs, and end-users in sour gas fields across the Middle East, Asia, and South America.