Meta Description:

Discover how stainless steel seamless tubes support high-performance mining and metallurgy operations across Chile, Peru, and Brazil. Learn about corrosion resistance, mechanical strength, and industry standards.

Introduction

South America is home to some of the world’s most significant mining and metallurgical hubs, particularly in Chile, Peru, and Brazil. With growing global demand for copper, lithium, iron ore, and rare earth elements, mining facilities are expanding—driving up the need for durable, corrosion-resistant piping systems.

DLSS supports this demand with high-performance stainless steel seamless tubes tailored for acidic, high-temperature, high-pressure mining environments.

1. Why Stainless Steel Seamless Pipes in Mining?

- Withstand abrasive slurries, acid leaching, and high-pressure slurry transport

- Ideal for underground dewatering, solvent extraction systems, and hydrometallurgical processing

- Resistant to H₂SO₄, HCl, and chloride-induced pitting

View corrosion resistance comparison data on Outokumpu’s stainless steel guide

2. Popular Grades for Mining Applications

| Grade | Use Case Example | Strengths |

|---|---|---|

| 316L / 316Ti | Acid leach piping, dewatering lines | Excellent corrosion resistance |

| 317L | High-chloride solution transport | Better pitting resistance than 316L |

| Duplex 2205 | Tailings transport pipelines | High mechanical strength + SCC resistance |

| Super Duplex 2507 | Heap leaching, pressure systems | Ultimate strength + corrosion resistance |

| Alloy 904L | Solvent extraction (SX/EW) systems | Acid resistance (sulfuric, phosphoric) |

We also provide customized TP304L, S31803, C276, and other alloys based on client needs.

3. Typical Applications in South American Projects

| Country | Sector | DLSS Product Use Case |

|---|---|---|

| Chile | Copper mining | Solvent extraction piping, SX plants |

| Peru | Lithium & gold | High-purity solution loops, CIP lines |

| Brazil | Iron ore processing | Acid-resistant pipe networks, waste treatment |

| Bolivia | Rare earth elements | Pressure lines, neutralization system tubing |

4. DLSS Technical & Export Advantages

- EN 10204 3.1 / 3.2 MTC

- Third-party inspection (SGS, TÜV, BV)

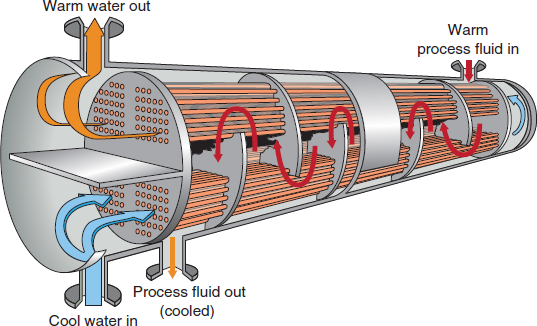

- U-bent tube for process exchangers

- PMI, UT, Hydro, EC & flattening test reports

- Packaging with PE wrap + seaworthy wooden crates

- Spanish bilingual documentation for customs clearance

Get more detail about EN and ASTM steel pipe standards

Frequently Asked Questions (FAQ)

Q1: What’s the best grade for H₂SO₄ acid environments in copper mining?

Grade 904L or Super Duplex 2507 performs best under sulfuric acid exposure at elevated temperatures.

Q2: Can DLSS supply thick-wall pipes for high-pressure slurry lines?

Yes. We offer customized SCH80, SCH160, and XXS wall thicknesses, with OD up to 114.3 mm and length up to 12m.

Q3: What’s the export lead time to Chile or Peru?

Standard production takes 3–5 weeks. Shipping to Callao (Peru) or San Antonio (Chile) typically takes 30–40 days.

Q4: Is it possible to inspect pipes before shipment?

Absolutely. We welcome third-party onsite or video inspection, and provide full reports including PMI and hydro tests.

Conclusion

Mining and metallurgy demand piping systems that perform under stress—mechanical, chemical, and environmental.

DLSS delivers the reliability, material traceability, and support required for South America’s most demanding mineral operations.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com