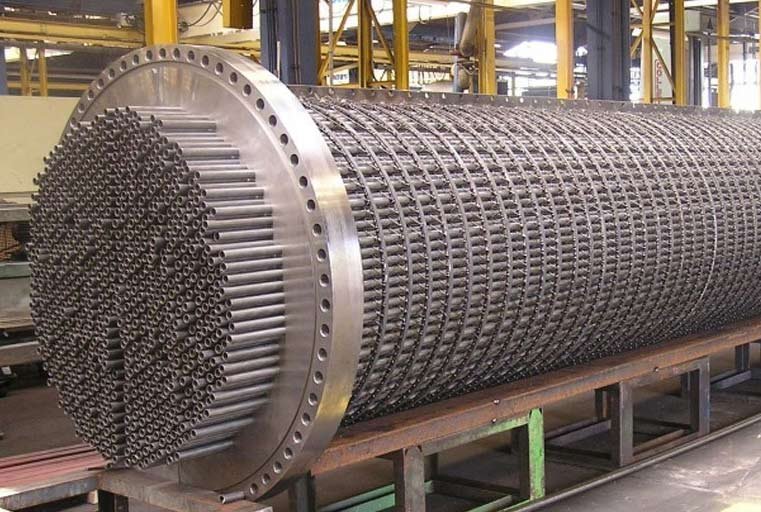

Stainless steel has become the material of choice for heat exchanger tubes across a wide range of industries. Its combination of corrosion resistance, mechanical strength, and cleanability makes it ideal for applications requiring durability and thermal efficiency. Choosing the right stainless steel grade is essential to maximizing performance and minimizing lifecycle costs.

This article explores the most common stainless steel tube grades used in heat exchangers, their performance characteristics, and industry-specific applications.

Why Stainless Steel?

According to Wikipedia – Stainless Steel, stainless steel is an iron-based alloy containing at least 10.5% chromium, which forms a passive film to resist corrosion. Its key benefits in heat exchanger applications include:

- High corrosion resistance in acidic, alkaline, and chloride environments

- Excellent strength-to-weight ratio

- Good thermal conductivity for indirect heat transfer

- Hygienic surface properties, easy to clean

- Long service life with reduced maintenance costs

Stainless steel is also recyclable and widely accepted in ASME, EN, and PED design codes.

Common Stainless Steel Grades for Heat Exchanger Tubes

| Grade | UNS No. | Features and Benefits | Applications |

|---|---|---|---|

| 304L | S30403 | General-purpose, low carbon, good weldability | HVAC, water treatment, general industry |

| 316L | S31603 | Added molybdenum for chloride corrosion resistance | Food & beverage, pharmaceuticals, marine |

| 317L | S31703 | Higher molybdenum, better pitting resistance | Chemical processing, pulp & paper |

| 904L | N08904 | High alloy, excellent sulfuric acid resistance | Petrochemicals, fertilizer, acid recovery |

| Duplex 2205 | S32205 | High strength + chloride stress corrosion resistance | Offshore, oil & gas, desalination |

| Super Duplex 2507 | S32750 | Higher PREN value, seawater-compatible | Seawater cooling, subsea equipment |

| Titanium Gr.2 | N/A | Extreme corrosion resistance in seawater | Marine, condenser tubes, desalination |

Compare technical data: AZoM – Stainless Steel Grades

Heat Exchanger Tube Standards & Specifications

At DLSS, all stainless steel tubes conform to international heat exchanger specifications such as:

- ASTM A213 / A269 / A789 – Seamless and welded tubes for boilers and heat exchangers

- EN 10216-5 – European standard for seamless stainless steel tubes for pressure purposes

- ASME Section II & VIII – Pressure vessel code requirements

- PED 2014/68/EU – Pressure Equipment Directive for CE marking

- Surface finish options: pickled, bright annealed, polished (Ra ≤ 0.4 µm)

Need help understanding material test reports? See Wikipedia – Mill Test Report

Application Scenarios by Grade

316L – Food Grade Excellence

Used extensively in food, beverage, and pharmaceutical industries for its hygienic properties and corrosion resistance. Polished tubes meet 3-A sanitary standards.

2205 Duplex – Offshore Strength

Excellent resistance to chloride-induced stress corrosion cracking, suitable for offshore oil platforms, FPSOs, and subsea systems.

904L – Acid-Proof Durability

Highly resistant to sulfuric acid, used in fertilizer plants, refineries, and chemical reactors.

Titanium – Marine Performance

Unmatched resistance to pitting and crevice corrosion in brine, seawater, and chlorinated water. Ideal for condensers in coastal power plants.

DLSS: Stainless Steel Tube Expertise

DLSS supplies high-precision, corrosion-resistant stainless steel tubes for heat exchangers worldwide. We offer:

- Tube diameters from 6mm to 60mm, wall thickness from 0.5mm to 5mm

- U-bending, cutting-to-length, polishing, and eddy current testing

- Tubing solutions tailored for petrochemical, power, food, HVAC, and marine industries

- Compliance with ASME, PED, NACE, and API 660 project specifications

More details:

DLSS Heat Exchanger Tube Solutions

Frequently Asked Questions (FAQ)

Q1: How do I choose between 304L and 316L stainless steel tubes?

316L contains molybdenum, offering better corrosion resistance, especially in chloride-rich environments.

Q2: What is the PREN value and why does it matter?

PREN (Pitting Resistance Equivalent Number) helps compare corrosion resistance. Higher PREN = better resistance to pitting.

Q3: Are your tubes suitable for ASME-certified pressure vessels?

Yes. DLSS tubes comply with ASTM and ASME standards and can be supplied with ASME-compliant MTCs.

Contact Us

Looking for reliable stainless steel tube solutions for your heat exchanger project?

Our engineers and export professionals are ready to support you with:

- Material selection advice

- Sizing and standard consultation

- Fast quotation and complete documentation

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

DLSS – Trusted by global clients in over 40 countries.