Meta Description:

South America’s oil and gas industry faces complex environments—from offshore Brazil to Andean gas fields. Learn why stainless steel seamless tubes are the smart choice for long-term reliability.

Introduction

South America is rich in oil and gas reserves—from Brazil’s offshore pre-salt basins, to Argentina’s Vaca Muerta shale, and Colombia’s expanding gas fields. These resources fuel the region’s economy but also demand high-performance, corrosion-resistant piping solutions.

In this article, we explore how stainless steel seamless tubes meet the challenges of South American energy projects and why companies across the region trust DLSS to deliver durable, NACE-compliant products.

Key Challenges in South American Energy Projects

Operating conditions across South America can be severe and highly variable:

- Offshore corrosion in Brazil’s Campos and Santos basins

- Sour gas service in the Andean highlands

- Remote midstream pipelines facing extreme temperature swings

- Environmental regulation and local certification requirements

These challenges demand piping materials that resist H₂S-induced cracking, maintain strength at high temperatures, and minimize long-term maintenance costs.

Why Stainless Steel Seamless Tubes?

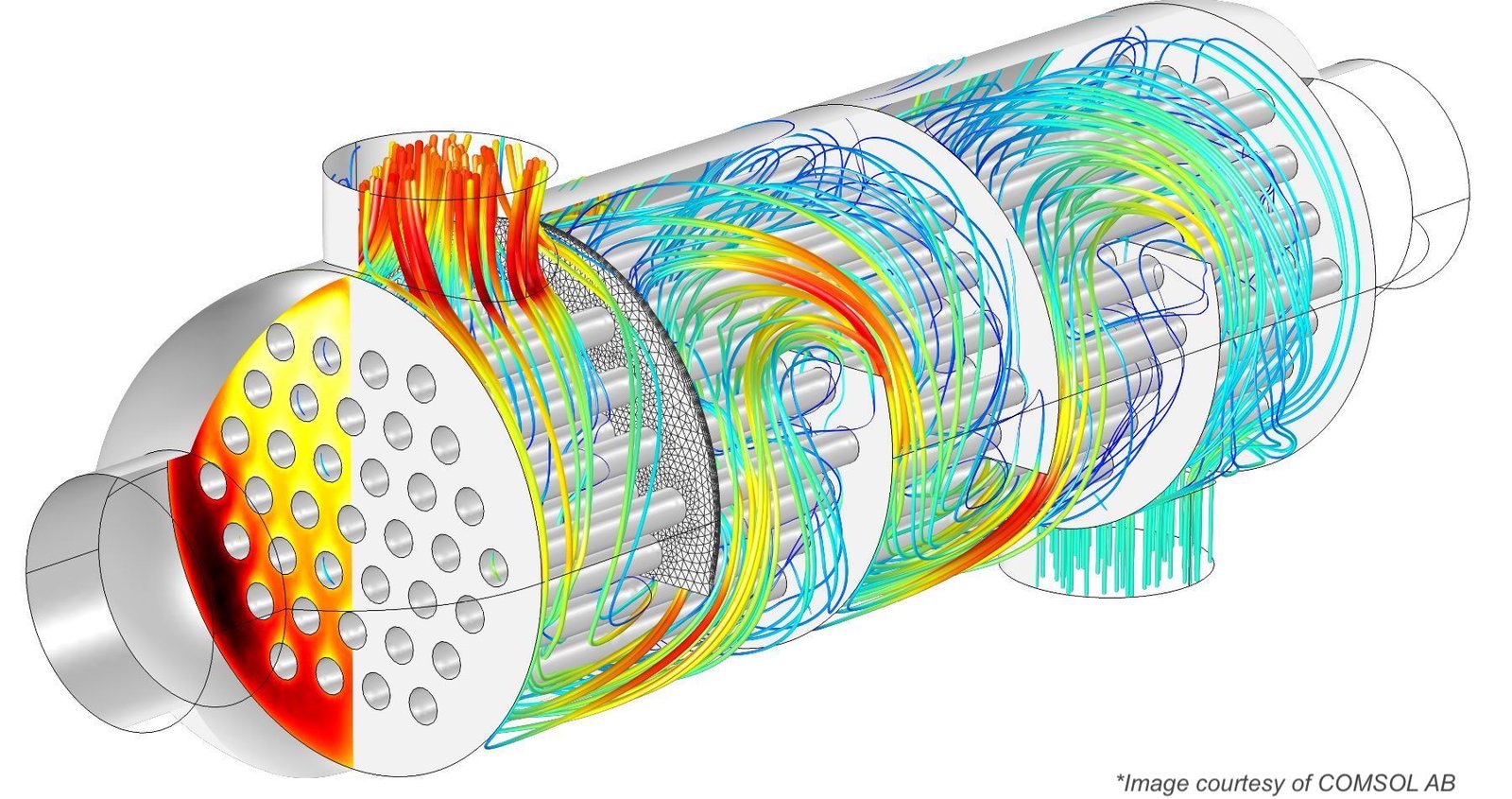

Unlike carbon steel or welded pipes, stainless steel seamless tubes offer a number of advantages for South American oil & gas projects:

- Superior corrosion resistance in saline, acidic, and sour media

- No weld seam, reducing risk of localized corrosion or weak spots

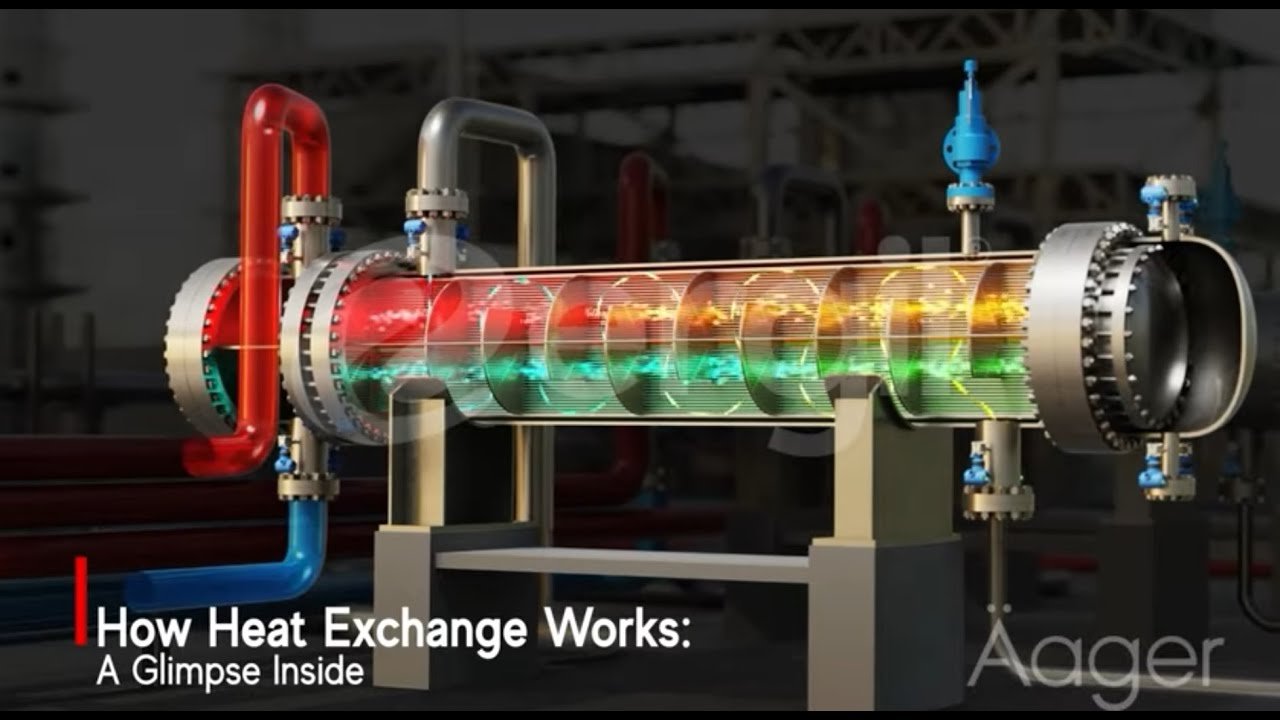

- Smooth interior surface, enhancing flow and minimizing buildup

- Compliance with NACE MR0175 / ISO 15156, essential for sour service

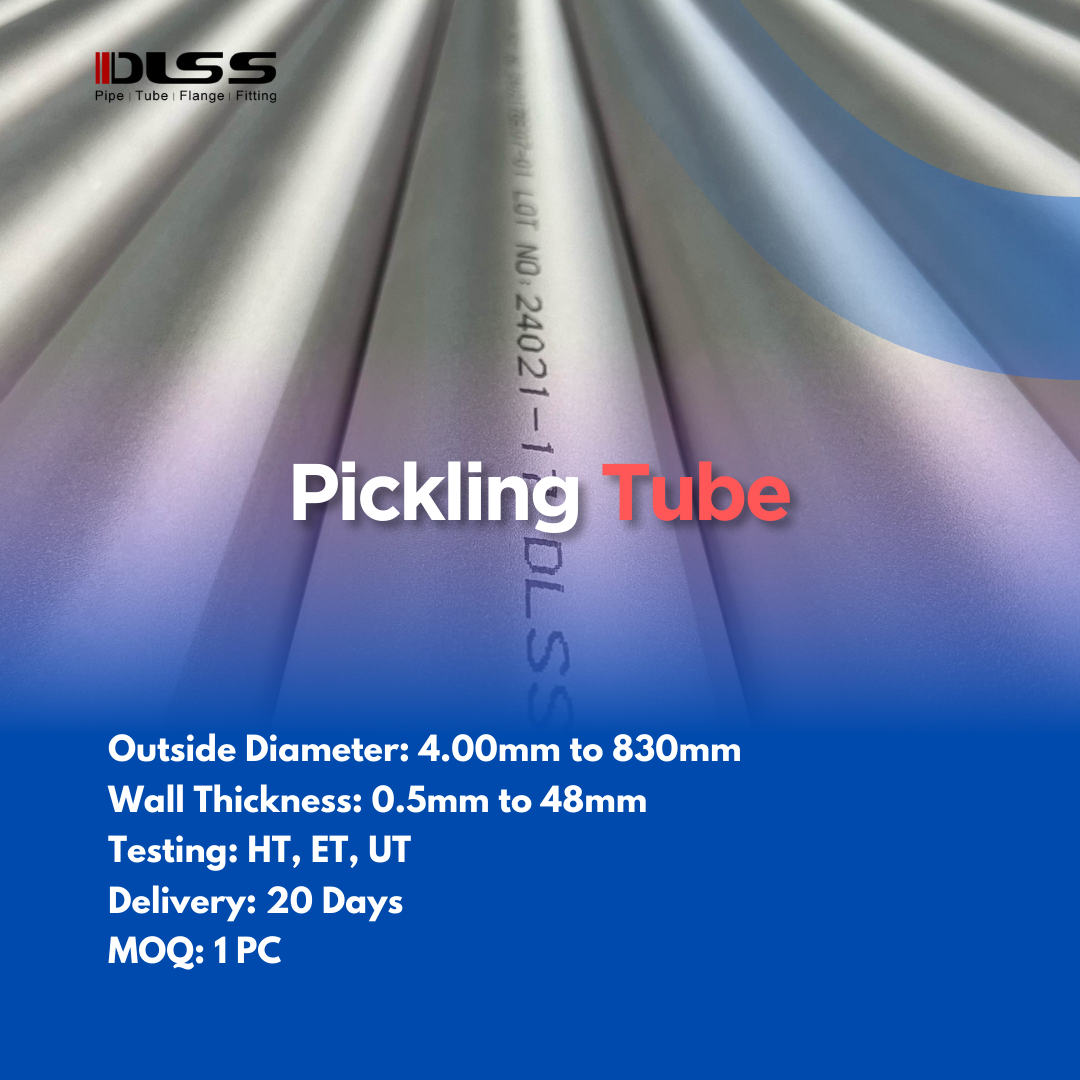

DLSS offers seamless tubing in OD 6mm to 219mm, lengths up to 12 meters, with pickled, BA, or EP surface finishes to suit specific field needs.

Popular Grades for South American Oil & Gas Applications

| Grade | Typical Application | Why It’s Used |

|---|---|---|

| TP316L | Offshore piping, platform systems | Chloride resistance + weldability |

| TP321 / 347H | Heat exchangers, thermal lines | High temp stability with stabilized chemistry |

| Duplex S31803 | Subsea risers, injection lines | Double strength + pitting resistance |

| Incoloy 825 | Sour service with H₂S and CO₂ | NACE MR0175 certified, excellent corrosion block |

| Alloy 625 | High-pressure/high-H₂S environments | Outstanding stress and fatigue resistance |

DLSS Success in Latin America

DLSS has supported EPC contractors and refinery operators in:

- Brazil: supplying TP316L seamless tubes for offshore skids and separators

- Argentina: providing NACE-tested Incoloy 825 tubes for gas processing modules

- Colombia: delivering pickled Duplex 2205 pipes for a new sour gas field

- Peru: partnering with local fabricators for refinery boiler tubes

All products include EN 10204 3.1/3.2 MTC, optional third-party inspections (SGS/BV/TÜV), and customizable markings in Spanish or Portuguese as needed.

Standards and Compliance You Can Trust

All DLSS products comply with:

- NACE MR0175 / ISO 15156

- ASTM A213 / A312 / B423

- ASME B31.3 and B31.4 pipeline design codes

- Latin America-specific pressure vessel and process piping regulations

Conclusion

As South America continues to expand its oil and gas infrastructure, selecting the right pipe material is more important than ever.

Stainless steel seamless tubes offer long-term corrosion protection, low maintenance, and performance under pressure—making them the preferred choice for offshore, midstream, and refinery applications.

DLSS is proud to support South American energy projects with high-quality materials, expert logistics, and project-ready documentation.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com