Meta Description:

Explore 7 common finned tube designs, how they differ, and which applications they serve best. Learn how to select the right fin geometry and material for your heat exchanger project.

Introduction

Not all finned tubes are created equal. With varying geometries, base materials, and manufacturing techniques, selecting the proper finned tube type can make a significant difference in thermal efficiency, service life, and cost.

This guide explores the 7 most common finned tube types used in industrial heat exchangers today—covering their characteristics, pros and cons, and where they perform best.

1. Embedded Finned Tubes

How It’s Made:

Metal fins (typically aluminum or copper) are mechanically embedded into the surface of a solid metal tube (often carbon steel or stainless steel).

Applications:

- HVAC systems

- Air-cooled condensers

- Heat recovery units

Benefits:

- Strong mechanical bond

- Efficient heat transfer

- Ideal for airside applications

2. Extruded Finned Tubes

How It’s Made:

The fins are formed from the base tube material itself by hot extrusion.

Applications:

- Offshore oil & gas platforms

- Marine cooling systems

Benefits:

- Excellent corrosion resistance

- Fins and tube are one solid piece

- Superior durability in extreme environments

Read more on extruded fin tube design

3. L-Type (Wrap-On) Finned Tubes

How It’s Made:

Thin metal fins are helically wrapped around the tube and tension-bonded.

Applications:

- Radiators

- Dry coolers

- Natural gas heater skids

Benefits:

- Simple, cost-effective

- Moderate fin-to-tube contact efficiency

- Good for moderate temperatures

4. G-Type (Grooved) Finned Tubes

How It’s Made:

Fins are forced into grooves cut into the tube surface, then rolled to lock.

Applications:

- High-pressure exchangers

- Process heaters

- Furnace coils

Benefits:

- Better thermal contact than L-type

- Stronger fin attachment

- Withstands vibration and thermal cycling

5. LL-Type Finned Tubes

How It’s Made:

Similar to L-type but with overlapped fins for better corrosion protection.

Applications:

- Corrosive environments

- Salt-laden air zones

Benefits:

- Improved fin root sealing

- Longer lifespan in harsh conditions

6. KL-Type (Knurled) Finned Tubes

How It’s Made:

Tube is pre-knurled; fins are applied under pressure and roll-formed into the knurl.

Applications:

- Power plant heat recovery

- Industrial furnace heaters

Benefits:

- Good mechanical strength

- Suitable for high thermal loads

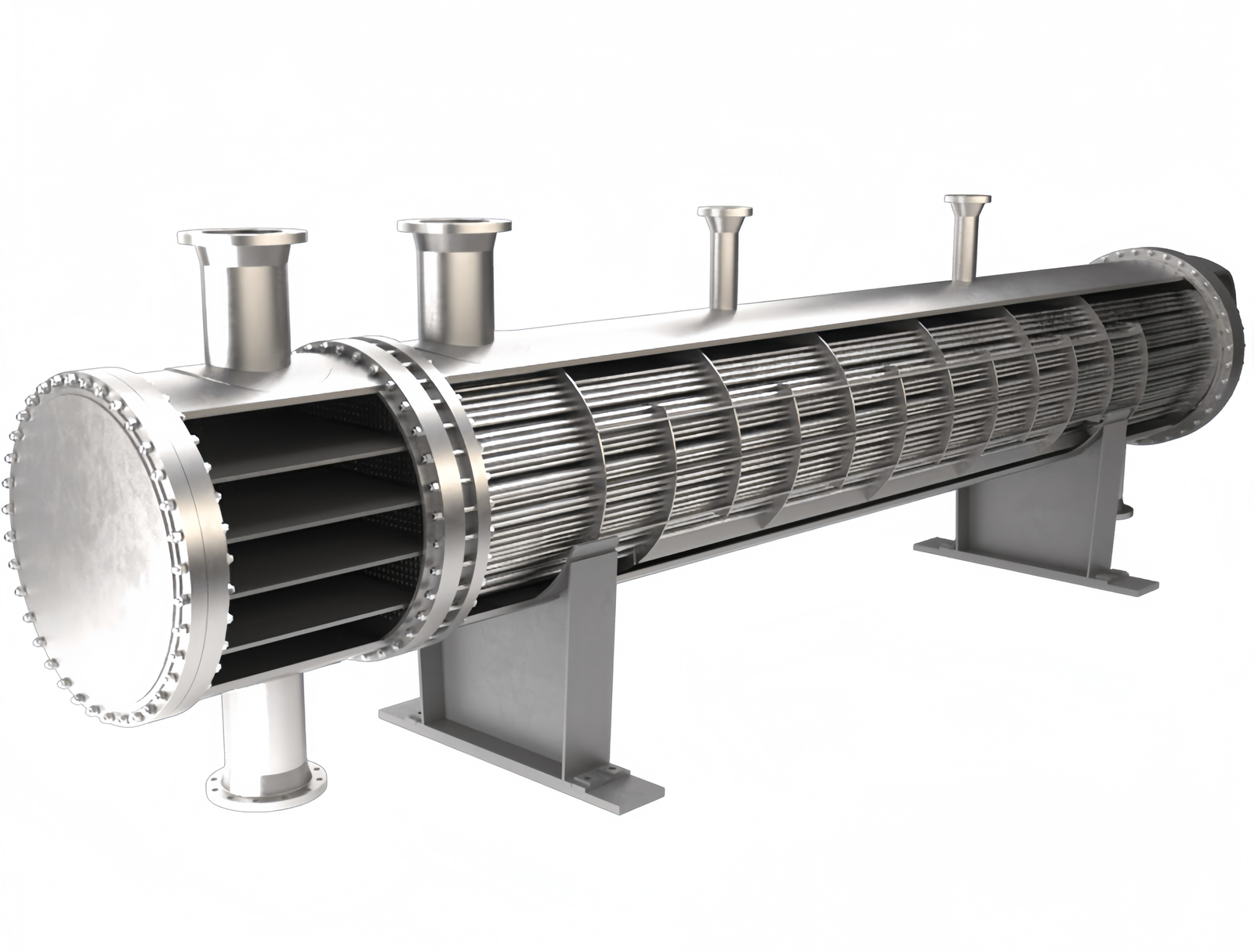

7. Longitudinal Finned Tubes

How It’s Made:

Flat fins are welded lengthwise to the exterior of the tube.

Applications:

- Vertical shell-and-tube exchangers

- Gland steam condensers

- Vertical gas heaters

Benefits:

- Excellent vertical drainage

- Suitable for viscous fluids

- Customizable fin spacing

DLSS Manufacturing Capabilities

DLSS supplies a wide range of finned tubes to suit different project demands:

- Tube Materials: Stainless steel (TP304L, TP316L, 321), CuNi 90/10, Carbon steel (SA-179, SA-210)

- Fin Materials: Aluminum, copper, stainless steel

- Tube OD: 12.7 mm – 50.8 mm

- Fin Heights: 5 mm – 20 mm

- Standards: ASTM A213, ASTM B111, EN 10216-5, NACE MR0175

Contact our team for help choosing the correct type for your operating conditions.

FAQs

Q1: Can I use extruded fin tubes for seawater cooling systems?

Yes. They’re highly resistant to corrosion and fouling, especially when made with CuNi or titanium base tubes.

Q2: Which fin type is best for vibration-prone environments?

G-type or extruded fins offer excellent mechanical strength and durability under vibration.

Q3: How do I know what fin height to choose?

Higher fins increase surface area but may also collect debris. Application-specific airflow and cleanliness will dictate the best height.

Conclusion

Selecting the right finned tube type is essential for achieving efficient, durable, and cost-effective heat transfer. Each design serves a unique purpose—choosing based on your operating pressure, temperature, corrosion conditions, and space constraints ensures optimal results.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Looking for expert advice on finned tube selection and supply? DLSS offers tailored solutions across energy, marine, HVAC, and chemical industries.