Meta Description:

Explore how duplex stainless steel tubes meet the demands of South America’s offshore energy sector. Learn about corrosion resistance, mechanical strength, and NACE compliance in deep-sea environments.

Introduction

From Brazil’s pre-salt fields to Colombia’s coastal gas terminals, offshore exploration in South America is pushing engineering materials to the limit. The tubes used in these operations must endure salt spray, H₂S gas, high pressure, and cyclic loads.

This is where duplex stainless steel tubes outperform traditional stainless steel and carbon steel options—offering the ideal balance of corrosion resistance, mechanical strength, and cost-efficiency.

What Is Duplex Stainless Steel?

Duplex stainless steels are a family of ferritic-austenitic alloys, typically containing:

- ~22% Chromium

- ~5% Nickel

- ~3% Molybdenum

- ~0.2% Nitrogen

Popular grades include UNS S31803 / S32205 (2205) and S32750 (2507).

They combine:

- The chloride resistance of austenitic steels (like 316L)

- The stress-cracking resistance of ferritic steels

- Higher strength—up to twice that of 304/316

Why Duplex Tubes for Offshore Use?

Offshore platforms in South America face:

- Constant saltwater exposure

- Presence of hydrogen sulfide (H₂S)

- Elevated temperature and pressure

- Long service life expectations (>25 years)

Duplex stainless steel tubes offer:

- ✔️ Superior pitting and crevice corrosion resistance (PREN > 35)

- ✔️ Resistance to chloride-induced stress corrosion cracking

- ✔️ NACE MR0175 compliance for sour service

- ✔️ Better weldability than super austenitic alloys

- ✔️ Lower total life-cycle cost than nickel alloys

South American Offshore Projects Using Duplex Tubes

| Project Location | Use of Duplex Tubes | Benefit Achieved |

|---|---|---|

| Brazil (FPSO Units) | Sea water cooling & chemical injection lines | Reduced maintenance & no pitting |

| Argentina (Gas Wells) | H₂S-bearing wellhead tubing | Full NACE compliance, longer uptime |

| Chile (Offshore Desalination) | Brine cooling coils | Superior seawater durability |

DLSS Duplex Tube Offerings

| Specification | Details |

|---|---|

| Grades | UNS S31803 / S32205 (2205), UNS S32750 (2507) |

| Standards | ASTM A789, ASTM A790, EN 10216-5 TC1 |

| Sizes | OD 6 mm to 114.3 mm, WT 0.7 mm to 8 mm |

| Surface Finish | Pickled, Bright Annealed (BA), Polished, Custom |

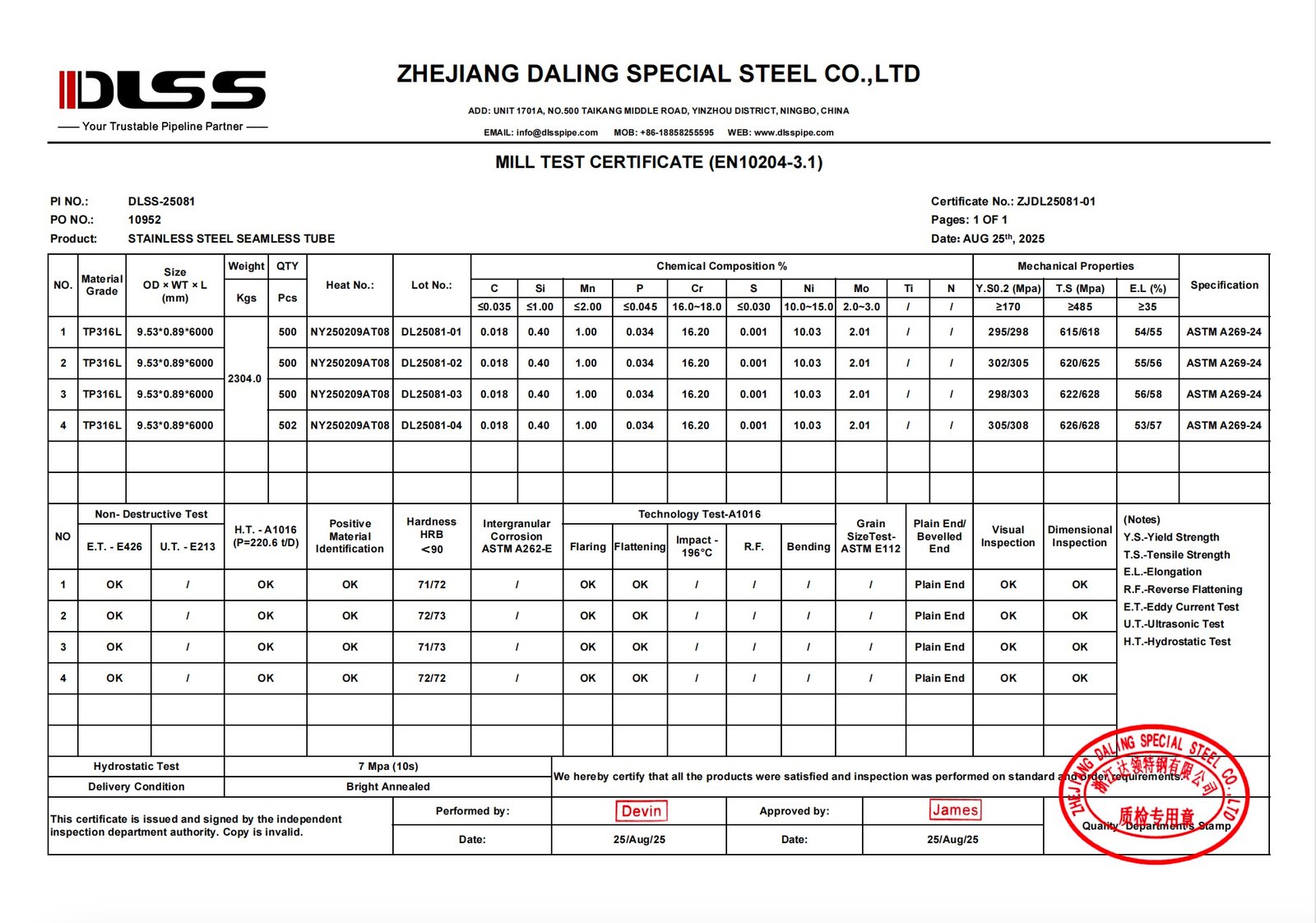

| Tests Offered | UT, ET, Hydrostatic, PMI, Intergranular, HIC/SSC if needed |

| Certifications | EN 10204 3.1 / 3.2 (BV, TUV, DNV), NORSOK MDS compliance |

FAQs

Q1: Is duplex steel more expensive than 316L?

Yes—typically 20–30% more per kg, but lasts 2–3× longer in corrosive environments, especially offshore.

Q2: Do you supply duplex with NORSOK or Petrobras specs?

Yes. We’ve supported clients with NORSOK MDS D45, IOGP requirements, and Petrobras weld procedure matching.

Q3: What is the delivery time for duplex tubes to Latin America?

Standard lead time is 30–45 days, depending on quantity and testing scope. Ports like Santos, Callao, and Buenos Aires are supported.

Conclusion

With expanding offshore exploration in South America, the demand for materials that can endure harsh marine and sour service conditions is rising. DLSS’s duplex stainless steel tubes offer a proven, reliable, and standards-compliant solution for long-term performance in critical offshore infrastructure.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need help specifying duplex tubes for your project? Our technical team can recommend grades, tests, and solutions tailored to South American environmental demands.