Introduction

Choosing the right stainless steel heat exchanger tube is critical to ensuring long-term performance, safety, and efficiency—especially in industries like petrochemical, power generation, and marine engineering. At DLSS, we’ve supported projects in over 35 countries and understand what matters most when it comes to tube selection.

In this article, we’ll share 5 key factors every engineer, purchaser, or designer should consider when selecting a stainless steel heat exchanger tube.

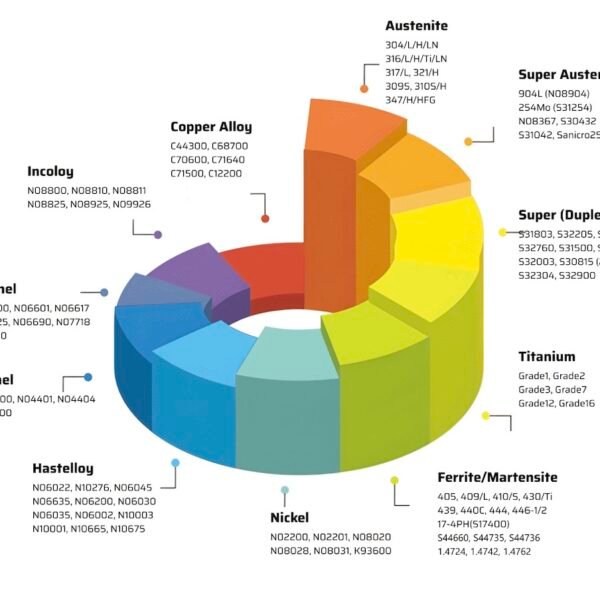

1. Tube Material Grade

The most common grades include TP304, TP316L, TP321, and Duplex Stainless Steel (like S32205).

- TP304 is economical but limited in chloride environments.

- TP316L offers enhanced corrosion resistance and is ideal for marine or chemical exposure.

- TP321 provides better high-temperature performance due to titanium stabilization.

- Duplex stainless steels combine high strength with excellent stress corrosion resistance.

Tip: Always match the grade to the working medium (e.g. seawater, steam, oil).

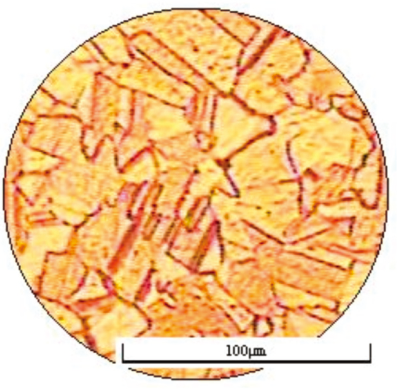

2. Corrosion Resistance Requirements

Different applications require varying levels of resistance to:

- Pitting and crevice corrosion (especially in chloride-containing environments)

- Intergranular corrosion (especially after welding)

- Stress corrosion cracking (SCC)

For high-risk applications, Molybdenum-containing grades like TP316L or Duplex are strongly recommended.

3. Operating Pressure and Temperature

Each material grade and wall thickness has a pressure-temperature rating.

- Thicker walls or higher alloy content are needed for high-pressure boilers or reactors.

- If the operating temperature exceeds 600°C, grades like TP321 or even nickel alloys should be considered.

Standards to Refer: ASTM A213, ASME SA213

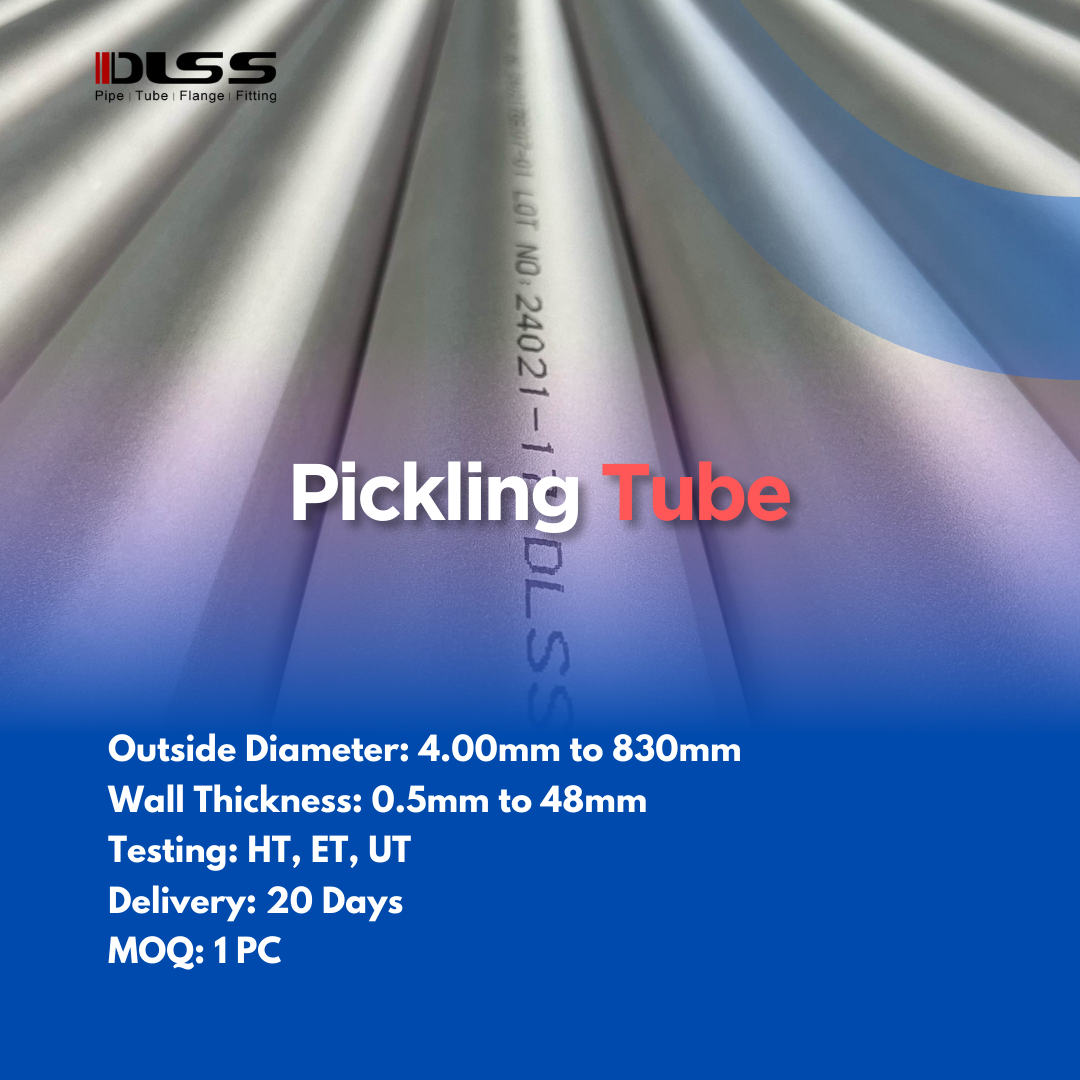

4. Surface Finish & Cleanliness

Surface condition affects heat transfer efficiency and hygiene.

Common options include:

- Pickled (clean, matte surface, corrosion-resistant)

- Bright Annealed (BA) (mirror-like, ultra-smooth surface for high-purity applications)

DLSS Advantage: We offer precision-pickled and bright annealed finishes for sanitary and high-efficiency usage.

5. Certification & Quality Assurance

International buyers should ensure compliance with:

- ASTM / ASME standards

- Hydrostatic & NDT tests (e.g. eddy current, ultrasonic)

- PMI (Positive Material Identification)

- Third-party inspection reports (SGS, TUV, BV, etc.)

A professional supplier like DLSS can provide full traceability, mill test certificates (MTCs), and custom testing reports.

Conclusion

Selecting the right stainless steel heat exchanger tube is not just about price—it’s about performance, safety, and long-term value. By focusing on the 5 key factors above, you can ensure the best tube selection for your project.

Why Choose DLSS as Your Stainless Steel Tube Partner?

With over 30 years of experience and exports to 40+ countries, DLSS offers:

- Customized tube solutions for heat exchangers and condensers

- Full compliance with ASTM/ASME standards

- Third-party inspections and full quality reports

- Precision production, fast delivery

Contact us today to get a free consultation or quote: info@dlsspipe.com