Introduction

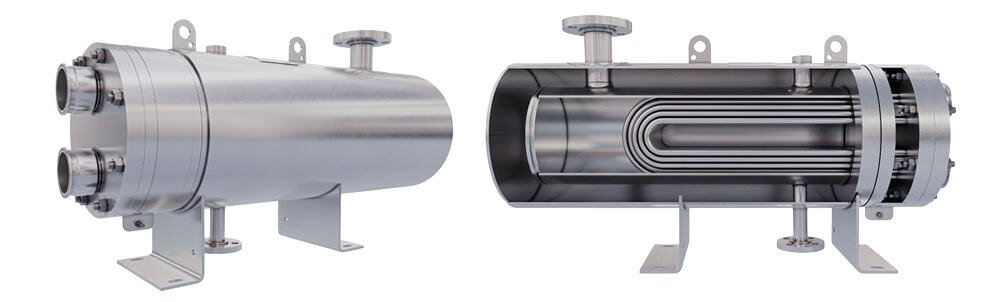

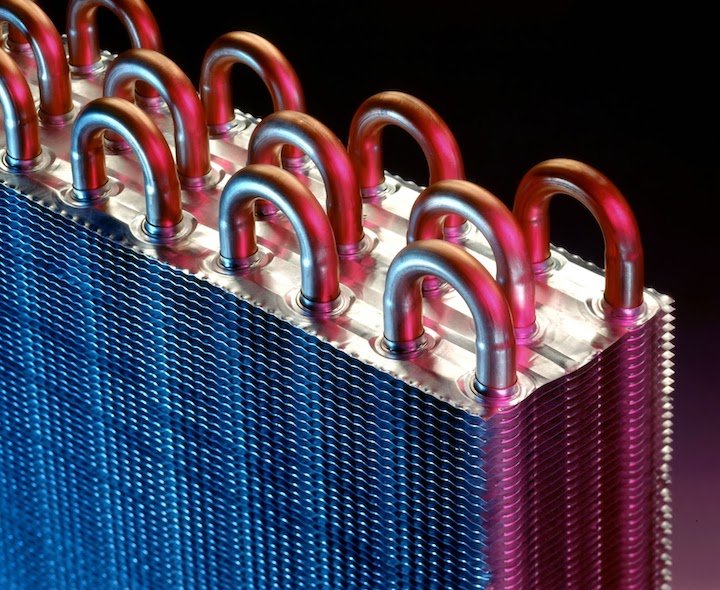

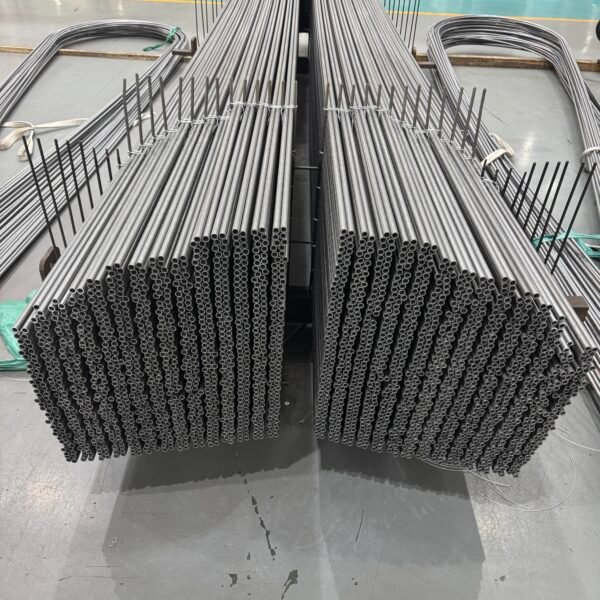

U-bent stainless steel tubes are essential in shell-and-tube heat exchangers, widely used in power generation, petrochemical processing, desalination, HVAC, and marine applications. These tubes are designed to efficiently redirect fluid flow while withstanding extreme thermal and mechanical stress.

At DLSS, we specialize in producing high-quality U-tubes with tight tolerances and global standard compliance. In this article, we explore 5 key U-bending standards, common applications, and material/technical insights to help buyers make informed decisions.

1. U-Bending Radius Standards

The minimum bending radius (R) is based on tube OD and wall thickness. Tight bends risk excessive thinning or cracking if not properly managed.

| Tube OD | Minimum Bending Radius (R) |

|---|---|

| ≤ 19.05 mm (3/4″) | ≥ 1.5 × OD |

| > 19.05 mm | ≥ 2.0 × OD |

DLSS offers U-bend radius from 1.5D to 3D, or customized per drawing.

2. Dimensional Tolerances (ASTM A556 / A688)

Precision is critical to ensure proper bundle fit and thermal efficiency. Our standard tolerances include:

- Leg Length: ±1.6 mm (0.063″)

- Center-to-Center Spacing: ±3.2 mm (0.125″)

- Ovality at Bend: ≤10% of OD

- Wall Thinning: ≤15% (DLSS typically controls ≤10%)

- Surface Finish: Pickled or Bright Annealed

DLSS uses CNC-bending machines and precision jigs for every U-bend.

3. Stress Relief Heat Treatment

Bending introduces stress that can cause microcracks or corrosion. For grades like TP316L, TP321, S32205, we recommend:

- Treatment Zone: U-bend + 150 mm of each leg

- Temperature: ~1050°C for solution annealing

- Cooling: Water quench or inert gas

- Traceability: Heat treatment charts & furnace logs available

DLSS performs in-house stress relief annealing per ASTM A213 or A688 standards.

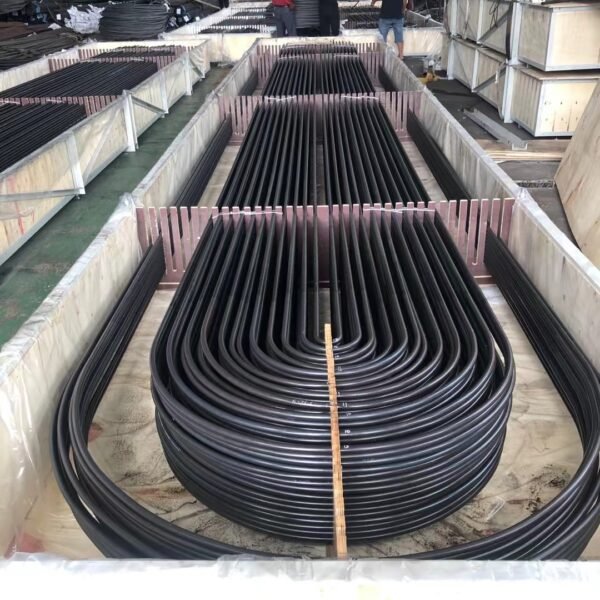

4. End Protection & Export Packaging

We ensure zero damage during transport with:

- Plastic end caps

- Leg separation with foam or film

- Plywood crate or steel frame bundling

- Radius support with wooden blocks

- Labeling, barcoding, and seaworthy export packaging

Our packaging is SGS-approved and complaint-free across 30+ countries.

5. Industry Applications & Recommended Grades

| Industry | Applications | Recommended Grades |

|---|---|---|

| Power Generation | Steam condensers, feedwater heaters | TP304, TP321, TP316L |

| Petrochemical Plants | Heat recovery exchangers, process lines | TP316L, TP347, S32205 |

| Offshore Oil & Gas | High-pressure, chloride-rich media | S32205, S32750, TP316Ti |

| HVAC & Cooling | Chillers, evaporators, condensers | TP304, TP316L |

| Desalination | Brine heaters, distillate preheaters | TP316L, TP904L, Alloy 625 |

6. DLSS U-Bent Tube Sizing Capabilities

| Parameter | Capability |

|---|---|

| Outer Diameter (OD) | 6.0 – 38.1 mm |

| Wall Thickness (WT) | 0.7 – 3.5 mm |

| Leg Length | Up to 18 meters |

| Bending Radius (R) | 1.5D – 3.0D or customized |

| Straightness Tolerance | ±0.5 mm/m |

| Material Grades | TP304/316L/321/347, Duplex, Nickel Alloy |

DLSS also supplies U-bent tubes with eddy current testing, hydraulic testing, and PMI as required.

7. Common Stainless Steel Grades for U-Tubes

| Grade | Key Features | Notes |

|---|---|---|

| TP304 | Cost-effective, general corrosion resistant | Not for seawater or aggressive chloride media |

| TP316L | Excellent in chloride/acid environments | Most commonly used grade for U-bend tubes |

| TP321 | Titanium stabilized, high-temp resistant | Ideal for >600°C steam exchangers |

| TP347 | Niobium stabilized, good weldability | Similar to TP321 with better fabrication |

| S32205 (Duplex) | High strength, superior SCC resistance | Preferred in offshore, aggressive environments |

| TP310S | High Cr/Ni content, high temp resistance | Suitable for >1000°C applications |

| TP904L | Super austenitic, acid/brine resistant | Used in desalination, fertilizer plants |

| Alloy 625/825 | Nickel-based, ultimate corrosion protection | Used in nuclear, acid gas, and high-risk areas |

8. Applicable Standards for U-Bend Tubes

| Standard | Description |

|---|---|

| ASTM A213 / SA213 | Seamless alloy/stainless tubes for boilers & exchangers |

| ASTM A688 | Austenitic SS tubes with U-bending for condensers |

| ASTM A556 | Carbon steel feedwater heater tubes (U-type) |

| ASME Section II | Boiler and pressure vessel material compliance |

| EN 10216-5 | Stainless tubes for pressure applications (EU standard) |

| PED / AD2000 | Pressure equipment compliance in Europe |

9. Wall Thinning Control Post-Bending

| Standard | Max Allowable Thinning | DLSS Control Target |

|---|---|---|

| ASTM A688 / A556 | ≤ 15% of nominal WT | ≤ 10% |

| TEMA / EN 12952-5 | ≤ 12.5% of nominal WT | ≤ 10% |

DLSS uses internal mandrel-supported bending to minimize thinning and prevent structural compromise.

Why DLSS?

- In-house CNC bending + solution annealing

- Compliance with ASTM, ASME, PED, and customer drawings

- PMI, NDT, hydro test, heat logs included

- Export to 40+ countries with EPC references

- Expert in power plant, refinery, HVAC, and offshore tube solutions

Contact us today at info@dlsspipe.com

Visit: www.dlsspipeline.com