Meta Description:

Confused between ASTM A269 and ASTM A213 stainless steel tube standards? This guide compares their differences in application, mechanical properties, testing, and surface finish.

Introduction

When sourcing stainless steel tubes, understanding the applicable ASTM standards is crucial. Two commonly referenced specifications are ASTM A269 and ASTM A213.

While they may seem similar, these standards differ significantly in intended use, required testing, surface finish, and tolerances.

In this article, we compare ASTM A269 and ASTM A213, helping you select the right tube for your application.

Overview of ASTM A213

ASTM A213 covers seamless ferritic and austenitic stainless steel tubes intended for:

- Boiler tubes

- Superheaters

- Heat exchangers

- High-temperature service

Typical grades: TP304, TP304L, TP316, TP316L, TP321, TP347

Key Features:

- Mandatory heat treatment (solution annealing)

- Tighter wall thickness tolerances

- Mandatory nondestructive testing (NDT) like eddy current or hydrostatic

Overview of ASTM A269

ASTM A269 applies to seamless and welded austenitic stainless steel tubing used for:

- General-purpose fluid transport

- Low-pressure systems

- Instrumentation or utility lines

Typical grades: TP304, TP304L, TP316, TP316L

Key Features:

- Heat treatment is required only for certain sizes

- Available in bright annealed or polished finish

- NDT is optional unless specified by the purchaser

Comparison Table: A213 vs A269

| Feature | ASTM A213 | ASTM A269 |

|---|---|---|

| Tube Type | Seamless only | Seamless and welded |

| Application | Heat exchangers, boilers | General-purpose piping |

| Grades Covered | Ferritic & Austenitic SS | Austenitic SS only |

| Heat Treatment | Mandatory solution annealing | Mandatory for sizes >¼” OD |

| Surface Finish | Pickled / Bright Annealed | BA, pickled, or polished |

| Wall Thickness Tolerance | Tighter (ASTM A450 reference) | Less strict |

| NDT Requirement | Mandatory (hydro or eddy current) | Optional (unless requested) |

| Mechanical Properties | Specified & tested | Specified & tested |

| Typical End Use | Heat transfer systems | Utility tubing, instrumentation |

When to Use ASTM A213

Choose ASTM A213 tubes when:

- The system operates under high temperature or pressure

- Tubes are installed in shell-and-tube heat exchangers

- Third-party inspection or EPC project compliance is required

- Precise dimensional control and NDT are necessary

When to Use ASTM A269

Select ASTM A269 tubes when:

- The system is for fluid transfer or non-critical environments

- Cost efficiency is important

- Welded tubes are acceptable

- Surface finish (BA or polished) is a priority (e.g., food/pharma)

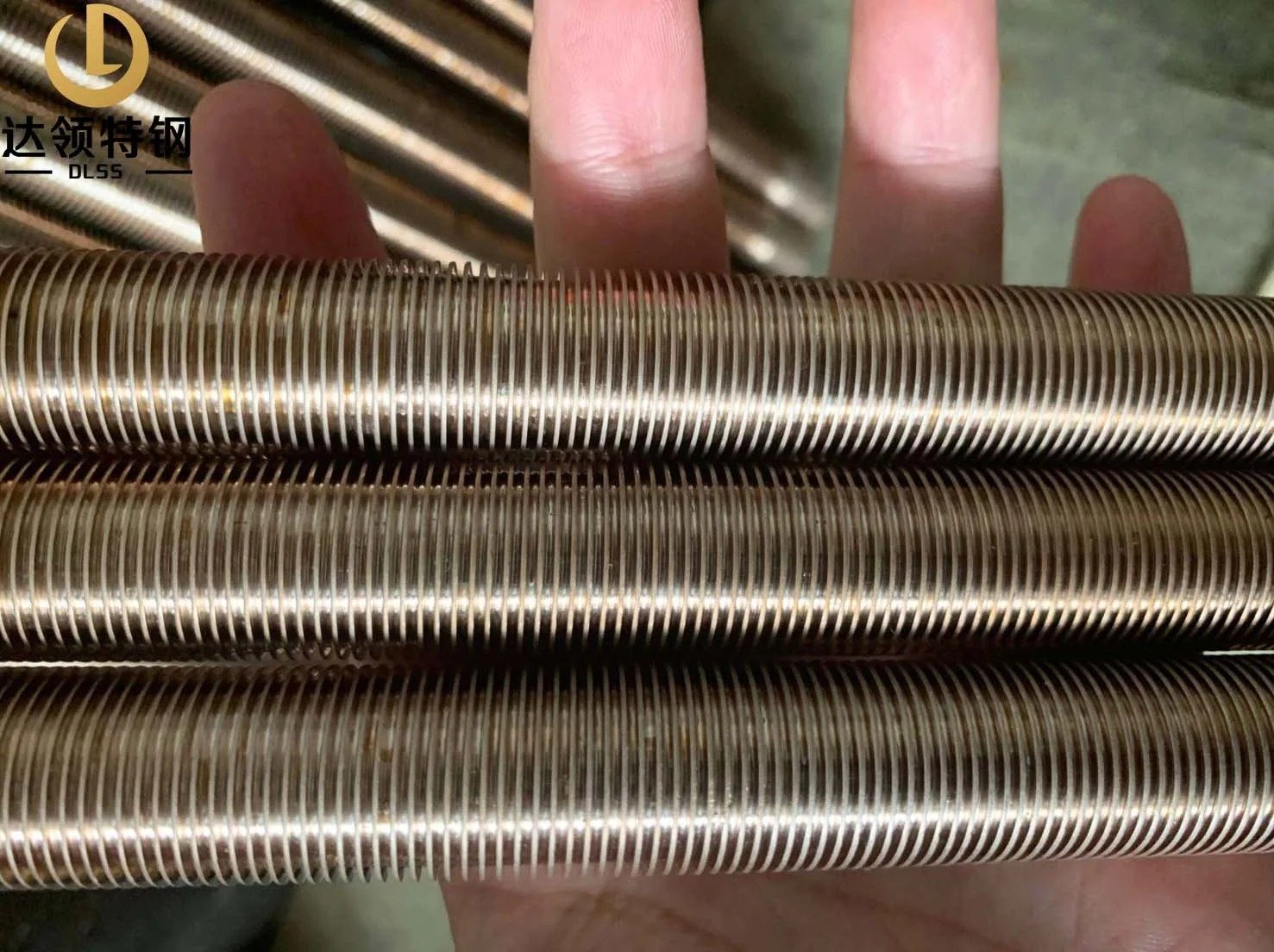

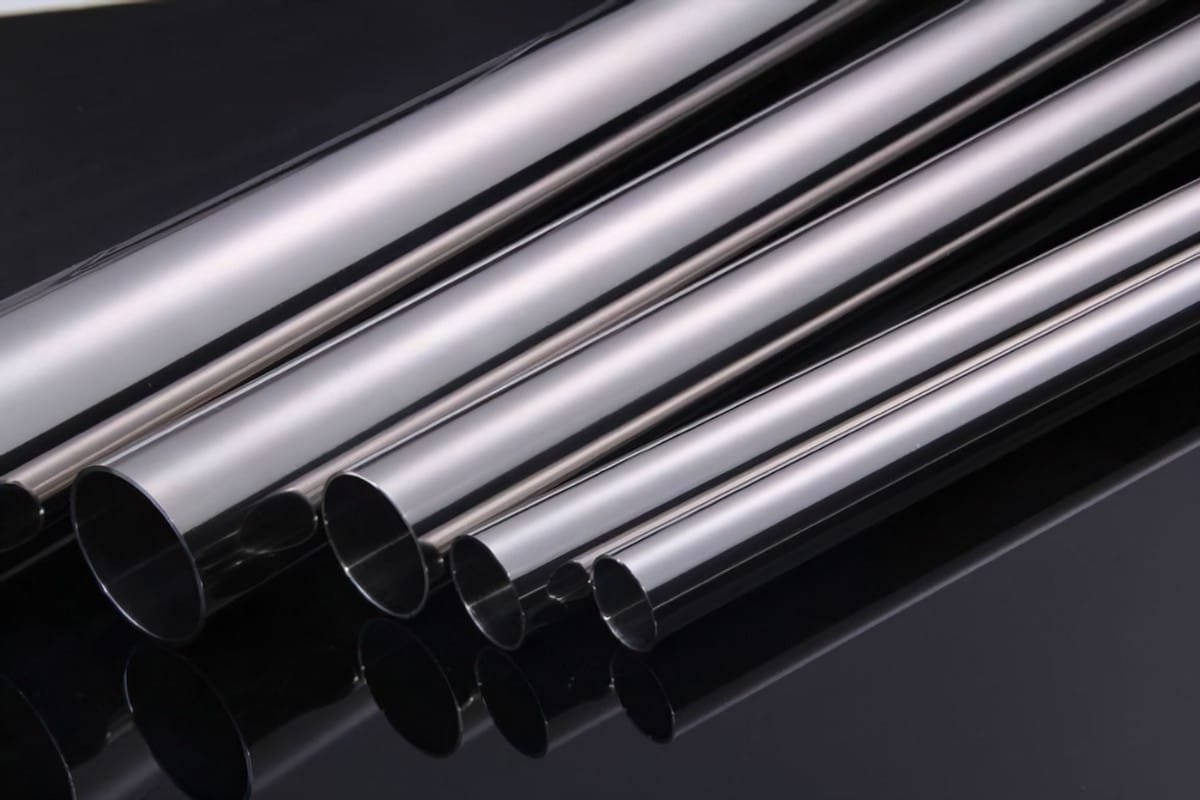

DLSS Capabilities

DLSS manufactures and supplies both ASTM A213 and A269 stainless steel tubes:

- Sizes: 6 mm – 38.1 mm OD, 0.5 – 3.5 mm WT

- Grades: TP304, TP304L, TP316L, TP321, TP347, Duplex S32205

- Surface: Bright Annealed, Pickled, Polished

- Tests: Hydrostatic, Eddy Current, PMI, Grain Size, Hardness

- Certification: EN10204 3.1 / 3.2, ASME-compliant

SEO Keywords

ASTM A213 vs A269 stainless steel, difference between A213 and A269, TP316L heat exchanger tubing standard, ASTM tube testing comparison, pickled vs BA finish tube, boiler tube standard ASTM A213, general purpose stainless pipe ASTM A269, DLSS tube supplier, seamless vs welded ASTM stainless tube, austenitic tube for pharma

Conclusion

Both ASTM A213 and A269 have their unique strengths. A213 is ideal for critical heat transfer applications, while A269 offers cost-effective solutions for utility or non-pressure systems.

DLSS ensures full compliance with both standards and can guide you through material selection and quality assurance.

Contact DLSS for Expert Tube Supply

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Let DLSS help you choose the right tube—certified, tested, and delivered with confidence.