Meta Description:

Explore the top 6 stainless steel industry trends in 2025, including green steel initiatives, duplex and super duplex stainless steels, nickel alloy pipes, and intelligent tube manufacturing.

1. Sustainable Stainless Steel Production

With the global push toward decarbonization, the stainless steel industry is rapidly transitioning to green steel production. In 2025:

- Over 60% of stainless steel products will be made from recycled content.

- Leading producers are adopting hydrogen-based metallurgy to significantly reduce CO₂ emissions.

- The EU Carbon Border Adjustment Mechanism (CBAM) encourages mills to adopt ISO 14001-certified production processes.

Key Keywords: green stainless steel, low-carbon stainless steel, ISO 14001 stainless tube supplier

2. Global Capacity Shifts and Import Pressure

According to CRU Group, stainless steel production is expected to stabilize globally, though China continues to dominate new capacity additions.

- European producers such as Outokumpu are scaling back investment due to weak margins and increased Asian competition.

- Buyers are now comparing domestic EN 10216-5 tubes with imported ASTM A312 seamless pipes based on total lifecycle cost and compliance.

Key Keywords: stainless steel import, EN 10216-5 tube, ASTM A312 seamless pipe, global stainless steel market

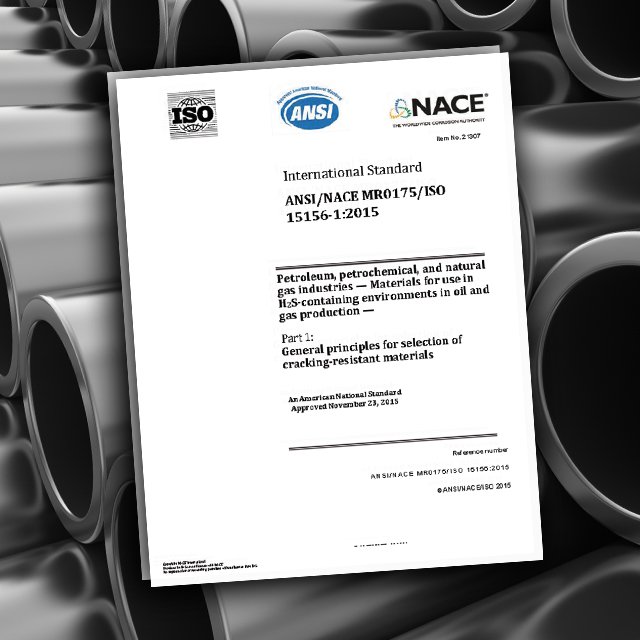

3. Rise of Advanced Alloys for Harsh Applications

Demand is surging for duplex stainless steel, super duplex pipes, and nickel alloy tubes in extreme environments such as:

- Offshore oil & gas

- Desalination and brine systems

- Sulfuric acid plants

- Heat exchangers in FPSOs and LNG terminals

Grades like S32750, Inconel 625, Alloy 825, and 254SMO are now considered essential for high-pressure, high-corrosion resistance.

Recommended Reading: Outokumpu Material Datasheets

Key Keywords: super duplex tube, Incoloy 825 pipe, Inconel 625 tubing, 254SMO heat exchanger tube

4. Intelligent Manufacturing of Stainless Tubes

Manufacturers are integrating AI-driven automation and IoT-based monitoring into the production of stainless steel tubes:

- CNC tube bending, automated U-bend shaping, and robotic inspection are improving consistency.

- Predictive maintenance via real-time sensor feedback reduces downtime and increases throughput.

- Digital MTCs and traceability platforms are becoming standard in tube mill operations.

Explore: Industry 4.0 in Steel Production – McKinsey Report

Key Keywords: stainless tube automation, CNC U-bend tube, intelligent tube production, digital traceability

5. Circular Economy and Recyclability

Stainless steel is inherently recyclable, with over 80% of material reused without degradation of mechanical properties:

- Lifecycle Assessment (LCA) is increasingly used to qualify suppliers.

- Clients prefer suppliers offering closed-loop packaging, returnable crates, and recyclable tube trays.

This aligns with corporate ESG goals and long-term environmental compliance.

Key Keywords: recyclable stainless pipe, LCA stainless steel, sustainable stainless steel supplier

6. Raw Material Cost & Trade Strategy

While nickel and molybdenum prices have stabilized, geopolitical risks still affect the cost and availability of stainless steel raw materials.

- Strategic sourcing from stable regions (e.g., ASEAN, Turkey) is growing.

- Importers must consider tariffs, anti-dumping measures, and origin rules in contracts.

Stay Updated: LME Nickel Price Tracker

Key Keywords: nickel alloy tube price, molybdenum surcharge, stainless pipe export

Summary Table: Key 2025 Stainless Trends

| Trend | Key Impact Areas |

|---|---|

| Green steel | Lower emissions, recycled content, ISO 14001 |

| Advanced alloys | Better corrosion resistance, harsh environments |

| Smart manufacturing | Precision, efficiency, traceability |

| Circular economy | Reusability, ESG alignment, LCA-driven purchasing |

| Trade dynamics | Strategic sourcing, tariff planning |

Conclusion

As the stainless steel industry enters a new era defined by sustainability, alloy innovation, and smart technology, it’s critical to stay informed. Procurement professionals, project engineers, and EPC firms must adapt their sourcing strategies to match evolving standards, compliance requirements, and customer expectations.

DLSS is committed to delivering high-performance stainless steel tubes that meet global demands, from low-carbon 316L pipe to high-grade super duplex heat exchanger tubing.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Ready to source premium stainless steel solutions aligned with the 2025 market trends? Reach out to our technical team for tailored solutions, material recommendations, and documentation support.