Meta Description:

Learn everything about ASTM A213: scope, material grades, dimensional tolerances, mechanical properties, and test methods. Ideal for engineers, buyers, and project managers working with heat exchanger and boiler tubing.

Introduction

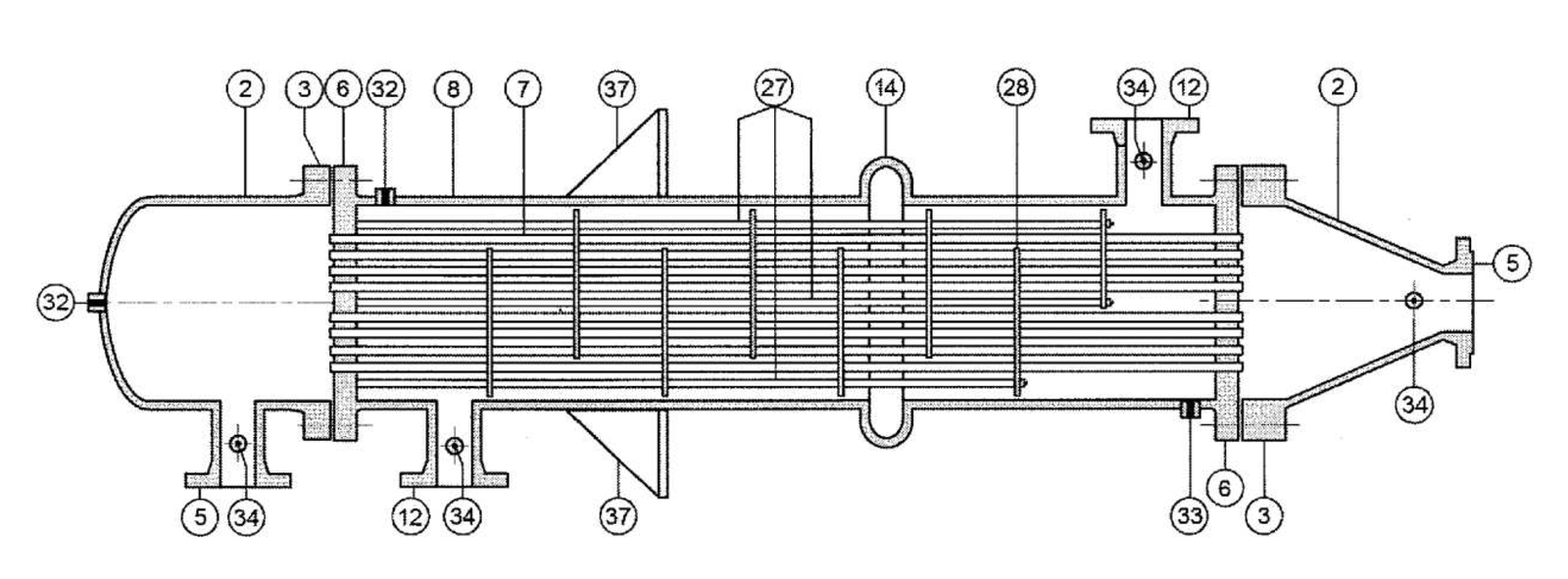

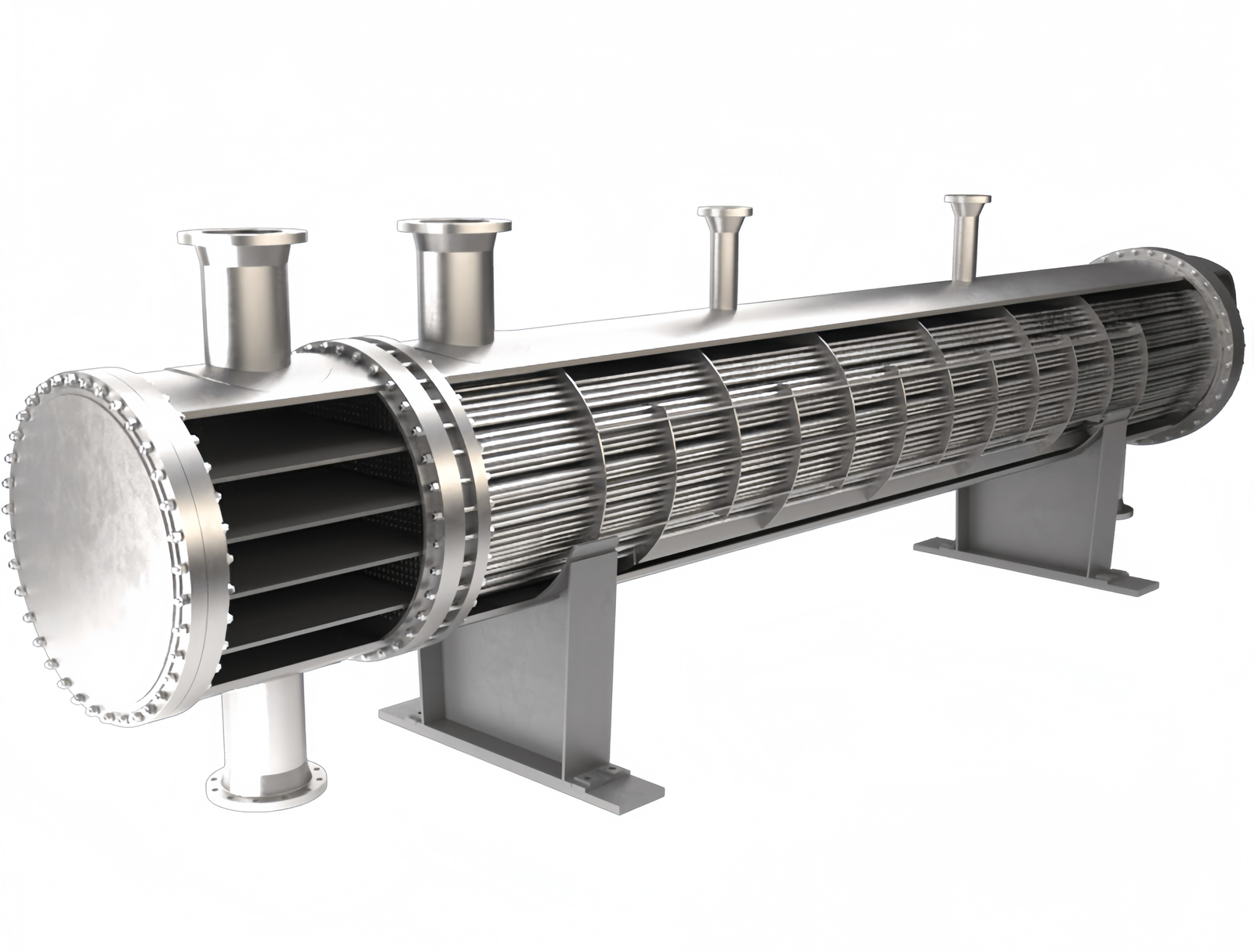

ASTM A213 is one of the most critical international standards for seamless ferritic and austenitic alloy steel tubes, especially those used in boilers, superheaters, and heat exchangers. If your project involves high-temperature or high-pressure tubing, understanding this standard is essential.

This guide offers a detailed overview of ASTM A213, including its scope, covered grades, mechanical properties, testing requirements, and how DLSS ensures full compliance.

1. What Is ASTM A213?

ASTM A213 is a specification developed by ASTM International for seamless tubes intended for:

- Heat exchangers

- Superheaters

- Boiler tubing

The standard covers both:

- Ferritic grades (like T11, T22, T91)

- Austenitic grades (like TP304, TP316, TP321, TP347)

Reference: ASTM Official A213 Document

2. Common Material Grades in ASTM A213

Austenitic Stainless Steel Grades

| Grade | UNS No. | Key Properties |

|---|---|---|

| TP304 | S30400 | Good general corrosion resistance |

| TP304L | S30403 | Low carbon for better weldability |

| TP316 | S31600 | Molybdenum for chloride resistance |

| TP316L | S31603 | Low carbon variant of TP316 |

| TP321 | S32100 | Stabilized with titanium |

| TP347 | S34700 | Stabilized with niobium |

| TP310S | S31008 | High temp oxidation resistance |

Ferritic Alloy Steel Grades

| Grade | UNS No. | Key Use Case |

|---|---|---|

| T11 | K11597 | Power plant tubes |

| T22 | K21590 | High-temp, medium pressure systems |

| T91 | K91560 | Advanced high-temp steam applications |

3. Key Requirements of ASTM A213

3.1. Chemical Composition

Each grade must meet strict limits on:

- Cr, Ni, Mo, C, N, Ti, Nb

- Ensures corrosion and oxidation resistance under high temperature

3.2. Mechanical Properties

Typical values for TP316L:

- Tensile strength ≥ 485 MPa

- Yield strength ≥ 170 MPa

- Elongation ≥ 35%

3.3. Dimensional Tolerances

- OD tolerance: ±0.79 mm (for OD ≤ 38.1 mm)

- WT tolerance: ±10%

- Lengths: Random, fixed, or cut-to-length as agreed

3.4. Surface Finish

- Must be free from scale, cracks, and other defects

- Pickled, bright annealed, or mechanically polished

4. Testing Methods

Required by ASTM A213:

| Test Name | Purpose |

|---|---|

| Flattening Test | Evaluate ductility and weld seam strength |

| Hardness Test | For grades with specified limits (e.g. TP304L ≤ 90 HRB) |

| Hydrostatic Test | Ensures no leakage under pressure |

| Nondestructive Test | Eddy current or ultrasonic (per E213, E426) |

| Grain Size Test | Austenitic grades: ASTM No. 5 or finer |

| PMI (Optional) | Confirms material composition |

5. Marking and Certification

Tubes must be clearly marked with:

- Grade (e.g., TP316L)

- Heat number

- Size and schedule

- DLSS brand or client logo (optional)

- Standard designation (ASTM A213)

Certifications:

- EN 10204 3.1 / 3.2 MTCs

- Additional test reports (IGC, Ra, PMI, NDT) upon request

6. DLSS Compliance & Capabilities

DLSS manufactures stainless steel tubes strictly to ASTM A213 using:

- Controlled cold drawing and bright annealing

- Full NDT, mechanical, and chemical testing

- Tight dimensional control for heat exchanger bundle fitting

- Tube sizes: OD 6–89 mm, WT 0.5–6 mm

- Surface: BA, Pickled, Polished, EP

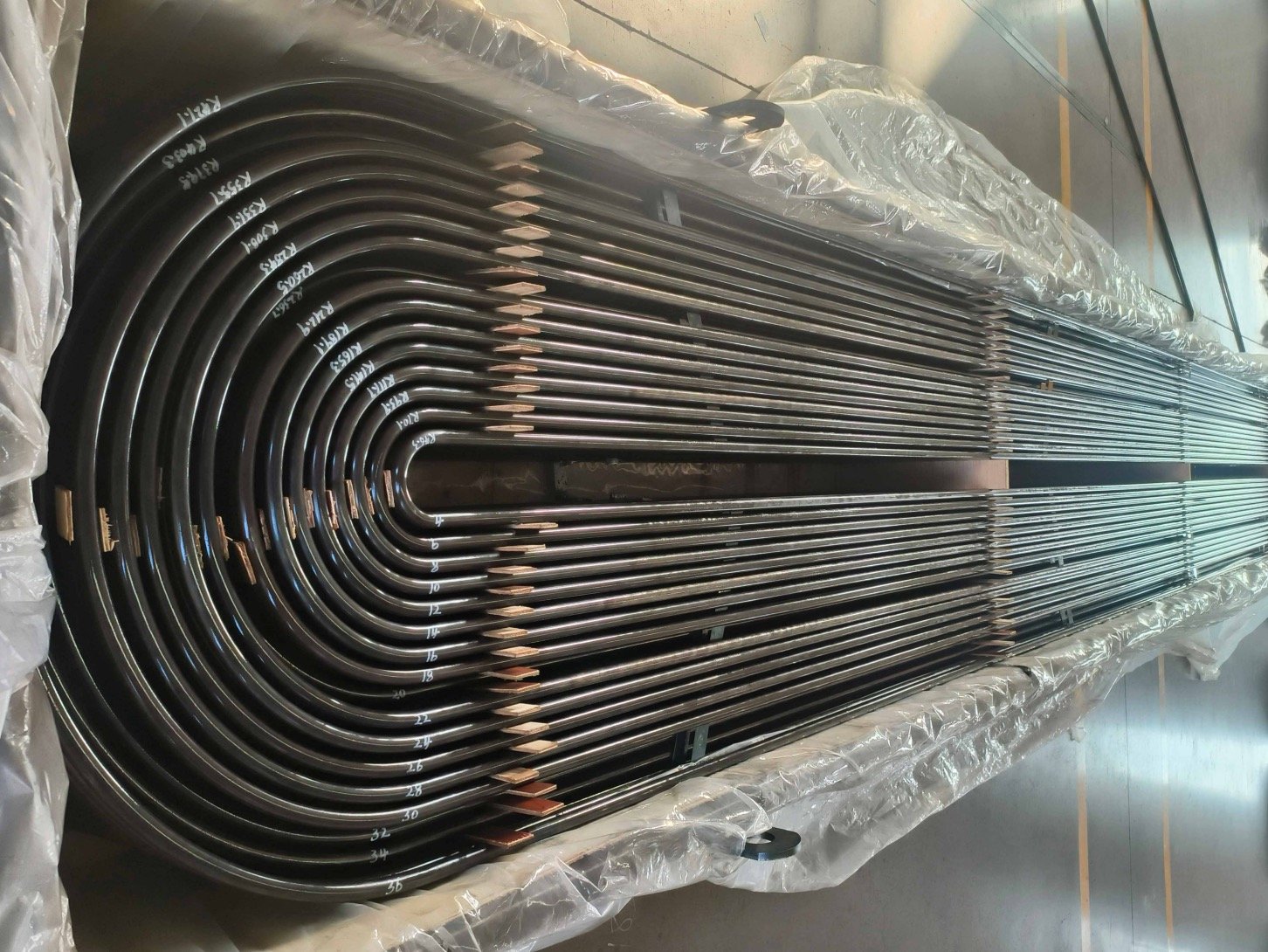

We also supply U-tubes and fin tubes made from ASTM A213-compliant material.

FAQs

Q1: Can ASTM A213 tubes be used for seawater applications?

Only certain grades like TP316L, TP904L, or duplex grades should be used due to chloride exposure.

Q2: Are the tubes pressure-rated?

Yes, hydro testing is mandatory unless otherwise specified.

Q3: Is surface Ra required for all ASTM A213 tubes?

Not required by default, but DLSS provides Ra test results for food, pharma, or EP tubes.

Q4: Can you provide tubes with U-bends?

Yes. DLSS supplies U-bent tubes per ASTM A213 + TEMA R / ASTM A556.

Conclusion

ASTM A213 is a comprehensive and demanding standard governing the production of seamless tubes for high-pressure, high-temperature applications. DLSS manufactures and certifies all products in full compliance with ASTM A213, offering high-quality solutions for heat exchangers, boilers, and industrial systems.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need ASTM A213-certified tubes for your next project? Contact us for instant support, mill test certificates, and competitive pricing.