Meta Description:

Do stainless steel seamless pipes really resist rust? Understand the science of corrosion, what causes rusting in stainless steel, and how to prevent failures in critical systems.

Introduction

A common question among engineers and procurement teams is:

“If it’s called stainless, can it rust?”

The name “stainless steel” suggests perfect rust resistance—but in reality, stainless steel can corrode under certain conditions. Understanding when and why this happens is essential to material selection and system reliability.

This article dives into the corrosion behavior of stainless steel seamless pipes, common risk factors, and how to prevent premature surface failure.

What Makes Stainless Steel “Stainless”?

Stainless steel contains at least 10.5% chromium, which reacts with oxygen to form a thin, invisible passive oxide layer that protects the underlying metal from corrosion.

According to Outokumpu’s stainless steel guide, this passive layer can self-heal when damaged—as long as enough oxygen is present.

But when that layer is disrupted—or environmental factors overwhelm its resistance—rust can form.

Common Causes of Rust in Stainless Steel Pipes

1. Chloride Attack

Pipes exposed to seawater, salt spray, or chlorinated process water are at risk of pitting corrosion. This is especially true for TP304 or TP304L.

Solution: use TP316L, Duplex, or Super Duplex stainless steels in chloride-rich environments.

2. Surface Contamination

Welding, grinding, or contact with carbon steel tools can introduce free iron particles, which become rust initiation points.

Solution: ensure proper pickling, passivation, or electropolishing after fabrication.

More info: ASTM A967 Guide for Stainless Steel Passivation

3. Lack of Oxygen

Ironically, stainless needs oxygen to stay corrosion-resistant. In stagnant or buried pipe systems, the passive layer cannot regenerate, leading to crevice corrosion.

4. High Heat or Stress

Welds and heat-affected zones can become sensitized, making them more prone to intergranular corrosion, especially in older TP304 grades.

Solution: use stabilized grades like TP321 or TP347, or low-carbon variants (L grades).

Grades Comparison: Rust Resistance

| Grade | Chloride Resistance | Typical Use |

|---|---|---|

| TP304 / TP304L | Moderate | Indoor water, decorative piping |

| TP316 / TP316L | High | Marine, food, chemical systems |

| Duplex 2205 | Very High | Oil & gas, offshore, sour service |

| Super Duplex 2507 | Extreme | Seawater injection, desalination |

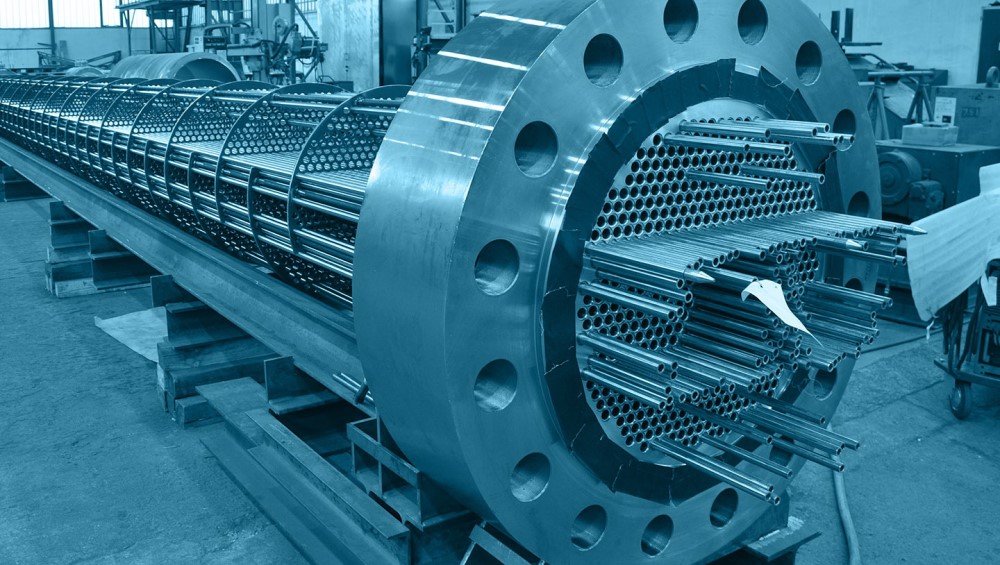

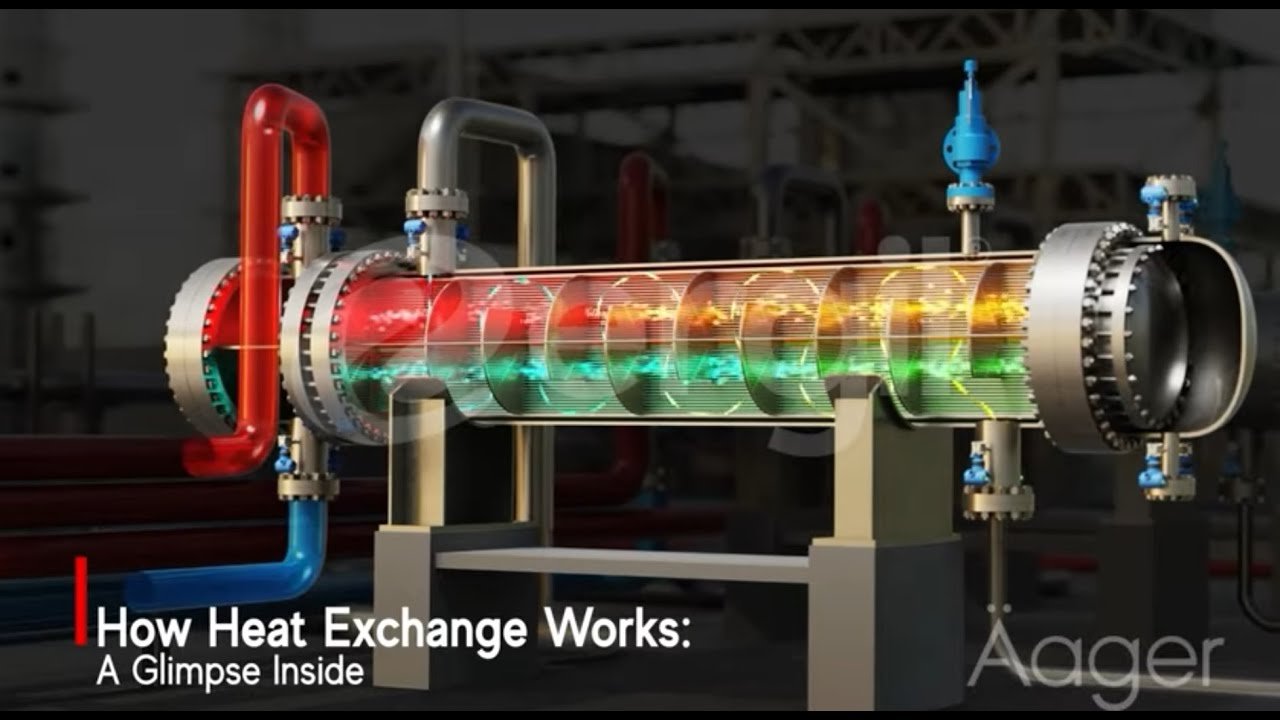

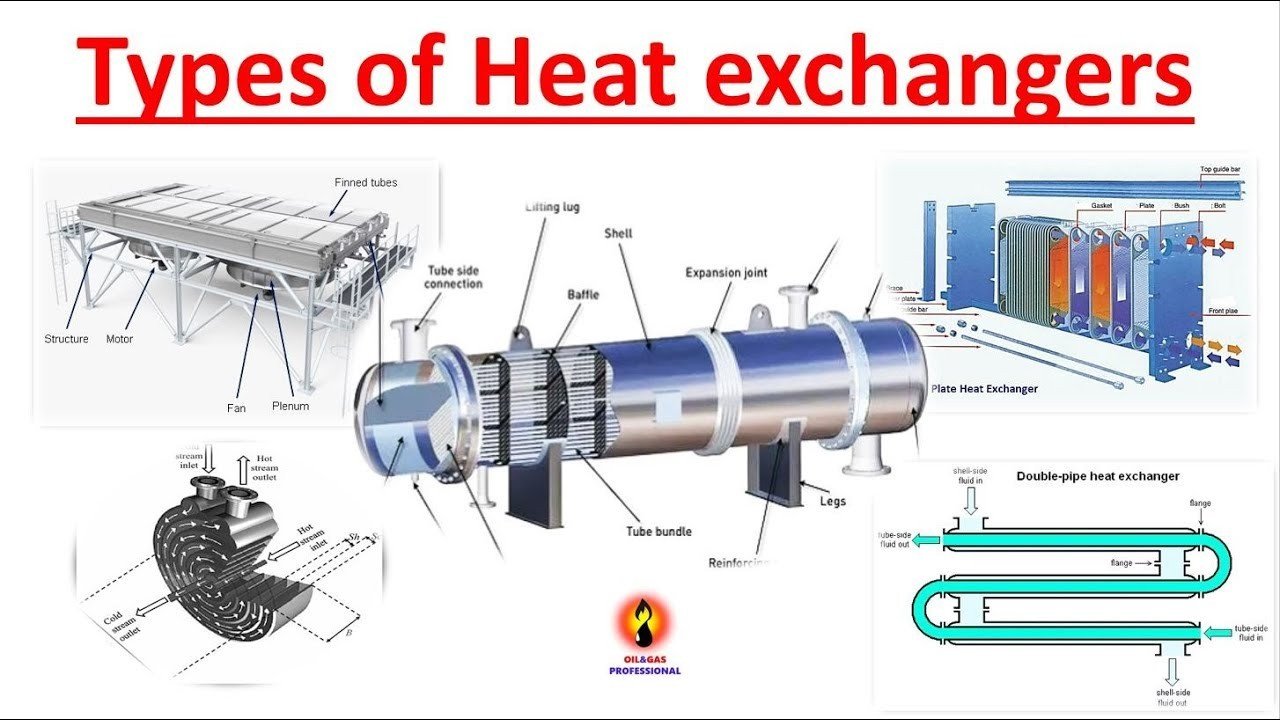

| Incoloy 825 | Excellent (Acid + H₂S) | Acid handling, heat exchangers in refineries |

How to Prevent Rust on Stainless Steel Pipes

- Choose the right material for the application

- Specify pickled or electropolished finish for high purity systems

- Avoid cross-contamination during storage or welding

- Apply protective coatings or wrap in aggressive coastal environments

- Perform regular inspection and cleaning of exposed piping

- Ensure proper design to eliminate stagnant zones or crevices

Frequently Asked Questions (FAQ)

Q1: Can stainless steel TP304 rust?

Yes. TP304 may rust in coastal or acidic environments. TP316L or Duplex is more suitable in those conditions.

Q2: Will rust on the surface affect the inside of the pipe?

Surface rust indicates exposure issues. If untreated, corrosion can spread, especially in thin-wall tubes or welded systems.

Q3: Is pickling or passivation required for all pipes?

Not always, but highly recommended for food, chemical, or pharma applications. See ASTM A967 for guidance.

Q4: What does DLSS do to prevent rust during shipping?

DLSS provides pickled, BA, or EP-finished seamless pipes with sealed ends, nitrogen purging (if needed), and protective packaging to minimize contamination.

Conclusion

While stainless steel seamless pipes offer outstanding corrosion resistance, they are not immune to rust. Rusting typically results from incorrect grade selection, fabrication errors, or harsh environments.

With proper surface finish, material choice, and storage protocols, DLSS stainless steel pipes can deliver decades of reliable, corrosion-free performance in demanding industries.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com