The demand for hygienic-grade stainless steel seamless tubes is rapidly expanding, particularly in the food & beverage (F&B) and pharmaceutical industries. These sectors require tubing with ultra-smooth surfaces, precise dimensional control, and strict compliance with international sanitary standards such as 3-A, ASME BPE, and ISO 2037.

In this article, we explore the latest market trends, hygiene and compliance requirements, and how DLSS Pipeline delivers seamless stainless tubing solutions designed for critical clean process applications.

1. Why Surface Quality and Cleanability Matter

In food and pharma processes, residue buildup or microbial contamination can lead to:

- Product spoilage

- Cross-contamination

- Regulatory non-compliance

- Risk to human health

To eliminate these risks, manufacturers demand tubing with:

- Ra < 0.8 μm (or even Ra < 0.5 μm for critical zones)

- Bright Annealed (BA) or electropolished (EP) internal surfaces

- 100% traceability and clean weldability

2. Global Compliance and Standards

| Standard | Region/Industry | Key Requirements |

|---|---|---|

| 3-A Sanitary | US dairy and food | Ra < 0.8 μm, clean-in-place (CIP) suitability |

| ASME BPE | Biotech & pharma (USA) | EP finish, sulfur content control, orbital welding |

| ISO 2037 | Global food & pharma | Dimensional tolerances, surface roughness, welding ends |

| EN 10357 | EU hygienic applications | Seamless/welded specs, pickled or polished finish |

DLSS supports compliance with these through precision production and surface treatment control.

3. Where Are Hygienic Tubes Used?

- Dairy processing systems

- Beverage and brewery production lines

- Pharmaceutical fluid transfer and filtration systems

- Cosmetic and personal care manufacturing

- Clean steam and WFI (water for injection) loops

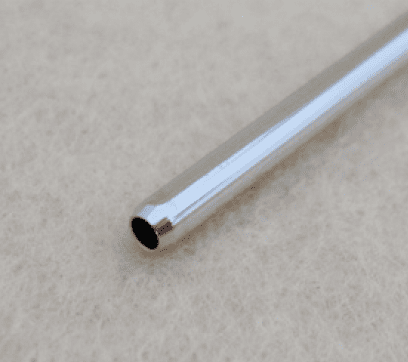

4. DLSS Hygienic Tube Capabilities

- Tube types: Seamless, straight-cut, coil, U-bend

- Finishes: BA, EP, AP, custom mechanical polish

- Grades: TP316L, TP304L, TP317L, 904L for aggressive media

- Ra options: 0.4 μm – 0.8 μm (verified with profilometer)

- Certifications: EN 10204 3.1, 3-A, ISO, customized CoC

- Packaging: PE film, end caps, sterile crate packing

See details: www.dlsspipeline.com

Frequently Asked Questions (FAQ)

Q1: What’s the difference between BA and EP finish?

BA is a bright mirror-like annealed surface, while EP is electrolytically polished for lower Ra and higher purity. EP is often required in biotech and pharma.

Q2: How can DLSS verify Ra values?

We perform internal surface roughness tests with certified profilometers. Digital reports and Ra photos can be provided upon request.

Q3: Can tubes be supplied with orbital weld prep?

Yes. We offer beveled ends, square cut, or orbital-ready prep depending on the welding process.

Conclusion

The food and pharmaceutical sectors are governed by strict hygiene regulations—and tubing quality plays a vital role in product integrity and process efficiency. DLSS delivers seamless hygienic tubes tailored for cleanroom and sanitary environments, with full documentation and export support.

Let DLSS Pipeline help you meet sanitary tube compliance and performance in your next clean process project.