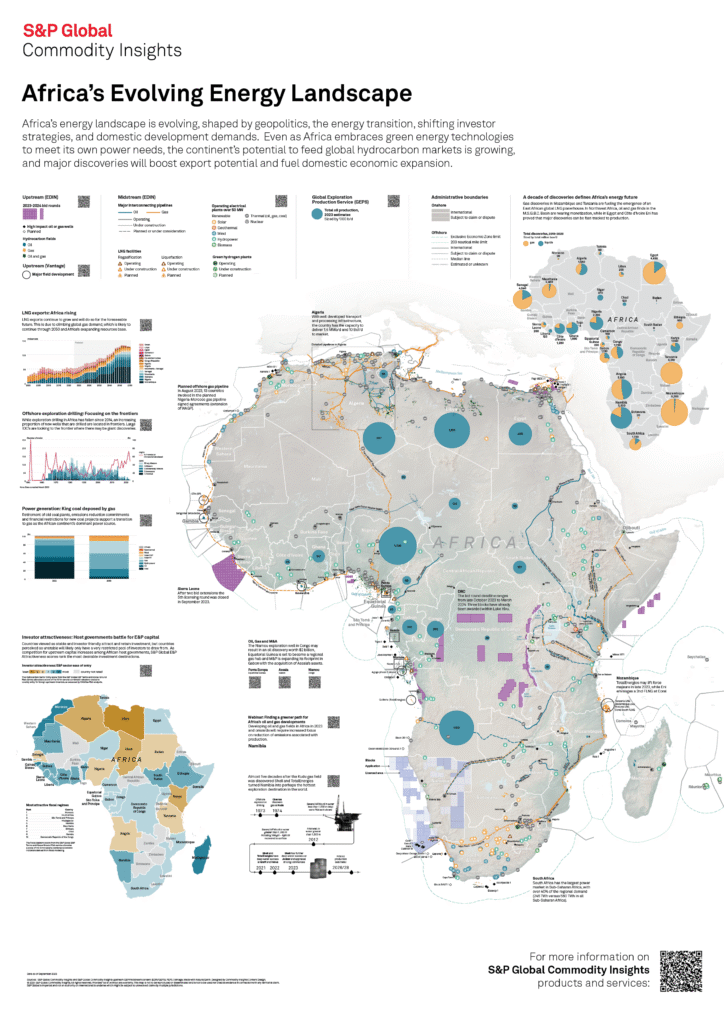

Africa is undergoing a once-in-a-generation infrastructure transformation. New refineries, LNG terminals, combined cycle power plants, and mining developments are emerging across Nigeria, Egypt, Algeria, Angola, Kenya, and beyond.

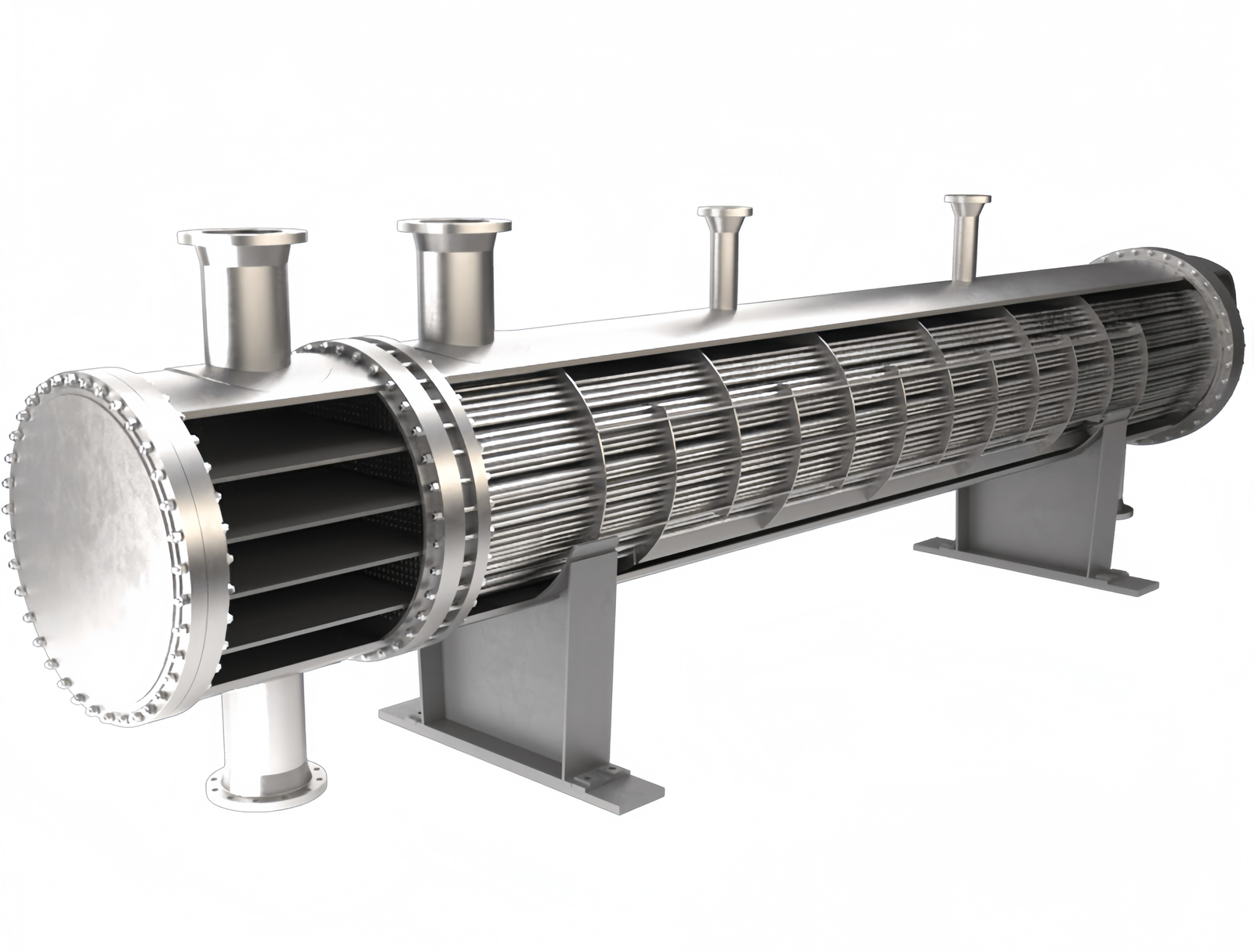

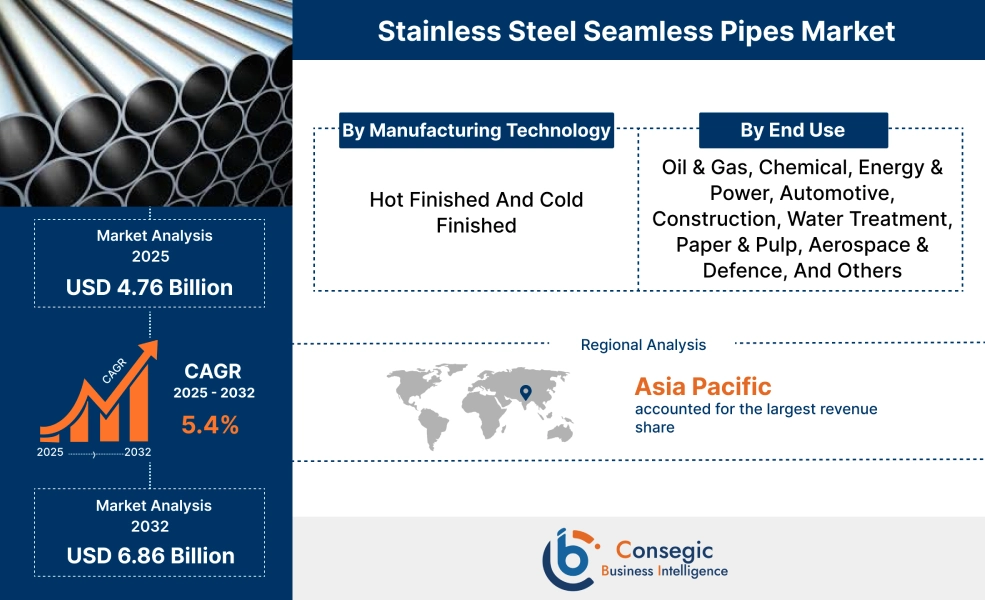

For stainless steel tube and pipe suppliers, this is not just a trend—it’s a new frontier. The continent’s demand for high-quality industrial piping, heat exchanger tubes, and pressure components is growing fast and diversifying.

1. The Projects Driving Demand

Here’s a snapshot of current mega-projects and their piping requirements:

| Country | Project | Product Needs |

|---|---|---|

| Nigeria | Dangote Refinery (650,000 bpd) | Large OD stainless steel piping, ASME heat exchanger tubes |

| Egypt | El-Dabaa Nuclear Power Plant | TP316L seamless piping, U-bend coils for heat removal systems |

| Algeria | Skikda LNG and Hassi R’Mel Gas Projects | Duplex and 904L alloy tubes, cryogenic-ready piping |

| Kenya | Geothermal Power Plants (Olkaria) | Corrosion-resistant geothermal tubes (TP304L, TP321) |

| Angola | Cabinda Refinery and gas pipeline expansions | Flanges, elbows, SA213 tubes, alloy steel headers |

Many of these projects are funded by public-private partnerships or with the support of Chinese, European, or Middle Eastern EPC firms.

2. Why Stainless Steel Tubing Is Gaining Ground

While carbon steel remains prevalent in basic piping, stainless steel tubes are increasingly selected due to:

- Resistance to corrosion, especially in coastal, high-salinity, or acidic conditions

- Suitability for high-pressure and high-temperature systems (steam, hydrogen, oil)

- Ease of maintenance and longer lifecycle for hard-to-reach areas

- Compatibility with renewable energy systems like geothermal or hybrid plants

Standards such as ASME SA213, ASTM A312, EN10216-5, and DIN 17458 are often specified.

3. Exporter’s Playbook: How to Enter and Succeed in Africa

African buyers and EPCs prioritize delivery certainty, document accuracy, and project experience. Here’s what stainless steel suppliers must prepare:

| Buyer Requirement | How to Respond |

|---|---|

| TPI documentation | Offer support for SGS/BV/TÜV inspection at your mill |

| Standard-compliant packaging | Fumigated wooden boxes, seaworthy markings, bundle labels |

| Multilingual paperwork | French or Arabic versions for North/West Africa may be needed |

| Flexible Incoterms | Some buyers prefer CIF or DAP to simplify import handling |

| Fast response times | Many projects are time-sensitive and buyers value speed |

Tip: Highlight past projects with refineries, mining operations, or power plants during your offers to establish credibility.

4. DLSS Case Study

In 2024, DLSS successfully delivered over 75 tons of TP316L stainless steel U-tubes and SA213 seamless piping for a sugar-mill energy recovery system in South Africa. The project demanded full traceability, 3.1 certificates, and BV inspection prior to shipment. DLSS met the timeline within 27 days, helping the customer restart the plant with improved efficiency.

Frequently Asked Questions (FAQ)

Q1: What stainless steel grades are most popular for African refineries?

A: TP316L, TP321, S32205 (duplex), and sometimes TP304H for high-temperature zones.

Q2: Are African buyers price-sensitive?

A: Yes—but increasingly they also value document compliance, performance, and service. Providing added value through fast quoting and technical advice helps win orders.

Q3: How are products usually delivered to Africa?

A: Through major ports like Lagos (Nigeria), Mombasa (Kenya), Durban (South Africa), and Alexandria (Egypt), often using 20’ or 40’ containers with wood-packed bundles.

Q4: Are third-party inspections required?

A: For government or EPC-funded projects—yes. Pre-shipment inspections by SGS, BV, or TUV are common and often mandatory.

Conclusion: Africa Is Not Waiting—Neither Should You

Africa’s industrial momentum is real. Projects are moving fast, and they need reliable partners who can deliver certified stainless steel tubing, offer flexibility, and back their claims with real project success.

If your company can ensure ASME-compliant delivery, provide bilingual documentation, and solve logistical challenges—Africa may just be your next strategic growth market.