Meta Description:

Explore how stainless steel seamless pipes improve corrosion resistance, reliability, and efficiency in shipbuilding. Learn key applications, material grades, and marine standards relevant for Latin American shipyards.

Introduction

In modern shipbuilding—whether it’s a container vessel in Brazil, a naval patrol boat in Chile, or a passenger ferry in Argentina—material selection is critical. Exposure to saltwater, pressure, vibration, and corrosion demands high-performance piping systems.

Stainless steel seamless pipes have become the go-to solution in many marine systems due to their excellent strength-to-weight ratio, resistance to pitting and crevice corrosion, and longevity in harsh environments.

Why Use Seamless Stainless Steel Pipes on Ships?

Shipboard systems require reliability under continuous motion, extreme temperatures, and exposure to seawater or chemicals. Stainless steel seamless pipes are preferred because they:

- Eliminate weld seams, reducing failure risk

- Offer uniform wall thickness and internal flow

- Are highly resistant to corrosion, especially in chloride-rich marine environments

- Require less maintenance than carbon steel alternatives

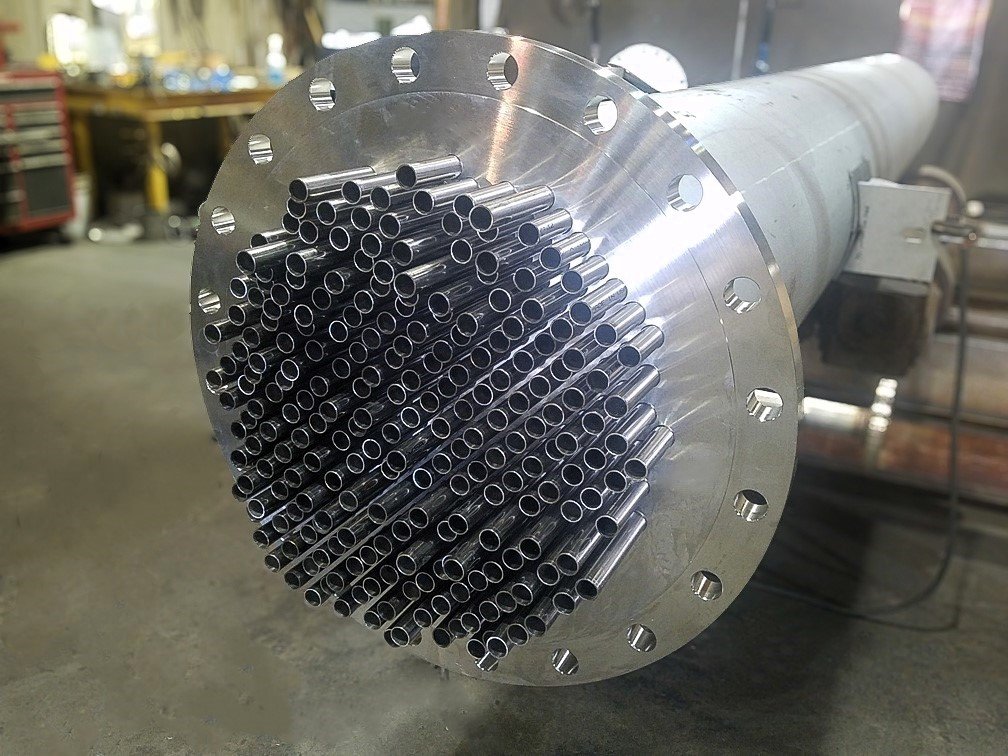

Key Marine Applications

| Ship System | Stainless Pipe Application | Material Recommendation |

|---|---|---|

| Ballast and cooling water lines | Long-life corrosion-resistant piping | TP316L, Duplex 2205 |

| Fuel and oil transfer systems | Precision and cleanliness, high-pressure tolerance | TP304L, TP316L |

| Firefighting systems | Corrosion-resistant safety-critical pipes | Super Duplex (UNS S32750) |

| Potable water / fresh water | Hygienic, non-leaching pipe materials | TP316L, TP304 |

| Wastewater and exhaust lines | Temperature and acid resistance | TP321, TP316Ti, 904L |

| HVAC and chiller systems | Seamless pipes for coil connections | TP316L, 1.4404 |

Recommended Grades & Standards

| Grade | Features | Standards Applicable |

|---|---|---|

| TP316L | Excellent saltwater and chemical resistance | ASTM A312, EN 10216-5 |

| Duplex 2205 | High strength, better pitting resistance | ASTM A789, ASTM A790 |

| TP321/316Ti | Heat resistance, anti-intergranular corrosion | ASTM A312, ASME SA312 |

| S32750 | For critical safety lines like firewater | ASTM A790, NORSOK MDS D45 |

| TP904L | High-performance corrosion in acidic media | ASTM B673, EN 10216-5 |

Read more: Stainless Steel in Marine Environments – Nickel Institute

DLSS Capabilities for Shipbuilding Projects

| Feature | Specification |

|---|---|

| Pipe Sizes | OD 6 mm to 114.3 mm, WT 0.7 mm – 8 mm |

| Surface Finish | Pickled, Annealed, BA, Custom as per client |

| Inspection Options | PMI, UT, Hydrostatic, Eddy Current, 3.2 certs |

| Standards Compliance | ASTM, EN, ASME, DNV, CCS, LR, ABS |

| Coating / Packaging | Anti-corrosion oiling, end caps, seaworthy cases |

| Delivery | Full export support to Brazil, Chile, Argentina |

Real Project Applications

- Chile Naval Yard: Duplex 2205 piping for seawater intake and deck drainage systems

- Brazilian Offshore Supply Vessel: TP316L seamless coils for HVAC & chillers

- Argentinian Ferry Refit: TP321 tubes used in high-temp exhaust and boiler piping

- Ecuador Ship Repair Dock: 904L piping for chemical tank barges

FAQs

Q1: Are your stainless pipes approved by marine classification societies?

Yes. DLSS can supply pipes with DNV, CCS, LR, or ABS approvals and full traceability.

Q2: Do you offer duplex or super duplex pipes for shipboard fire lines?

Yes. We supply both 2205 and S32750 grades with supporting tests and impact data.

Q3: Can you supply long coils for chiller/HVAC units?

Absolutely. Seamless coil tubes are available in lengths up to 600 meters per reel.

Conclusion

As shipbuilding technology advances across Latin America, stainless steel seamless pipes play an increasingly vital role in improving corrosion resistance, weight efficiency, and system reliability. DLSS offers the expertise, materials, and certifications needed for your next marine project.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need help selecting the right material and specification for marine-grade piping? Contact us for technical guidance and pricing.