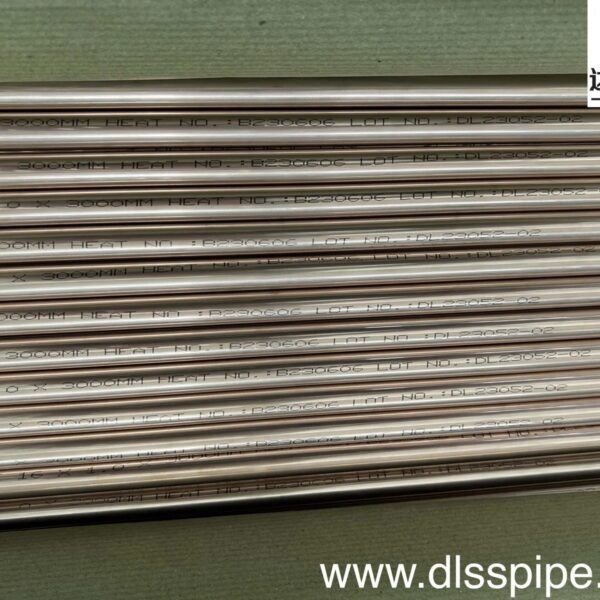

Product Overview: ASTM B111 C70600 Seamless Copper-Nickel Tube (16×1.0mm, 3000mm)

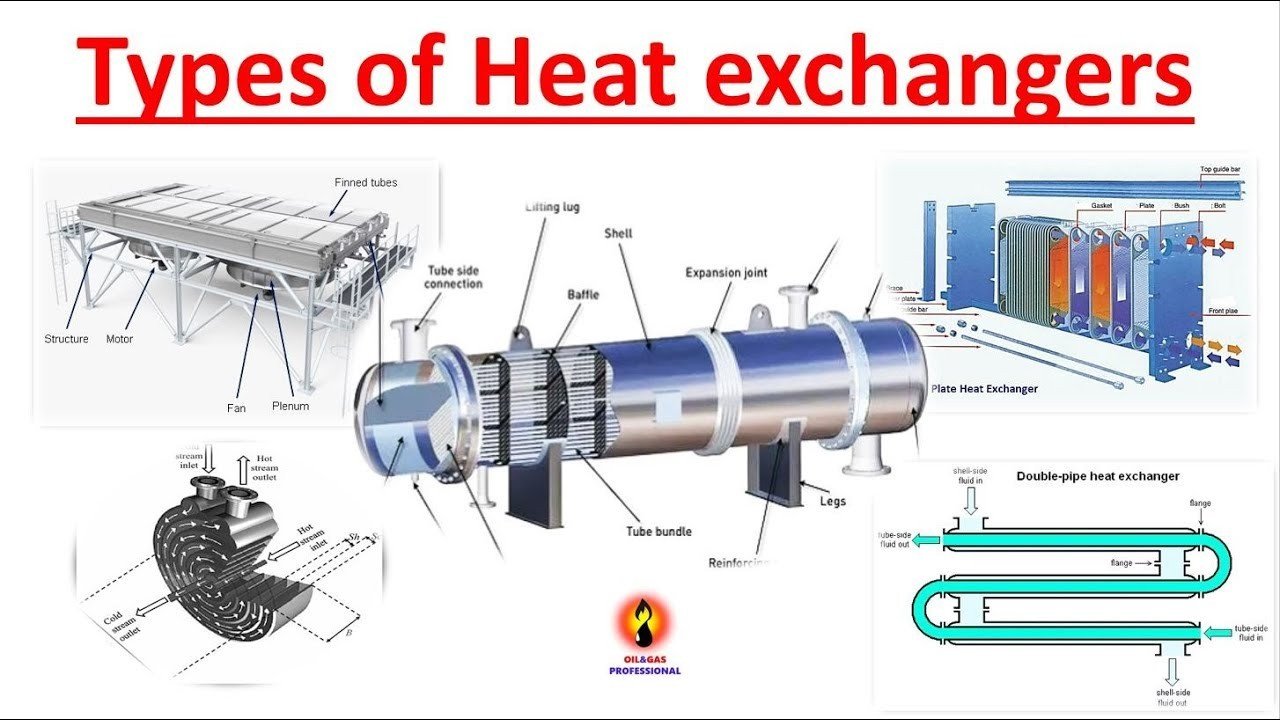

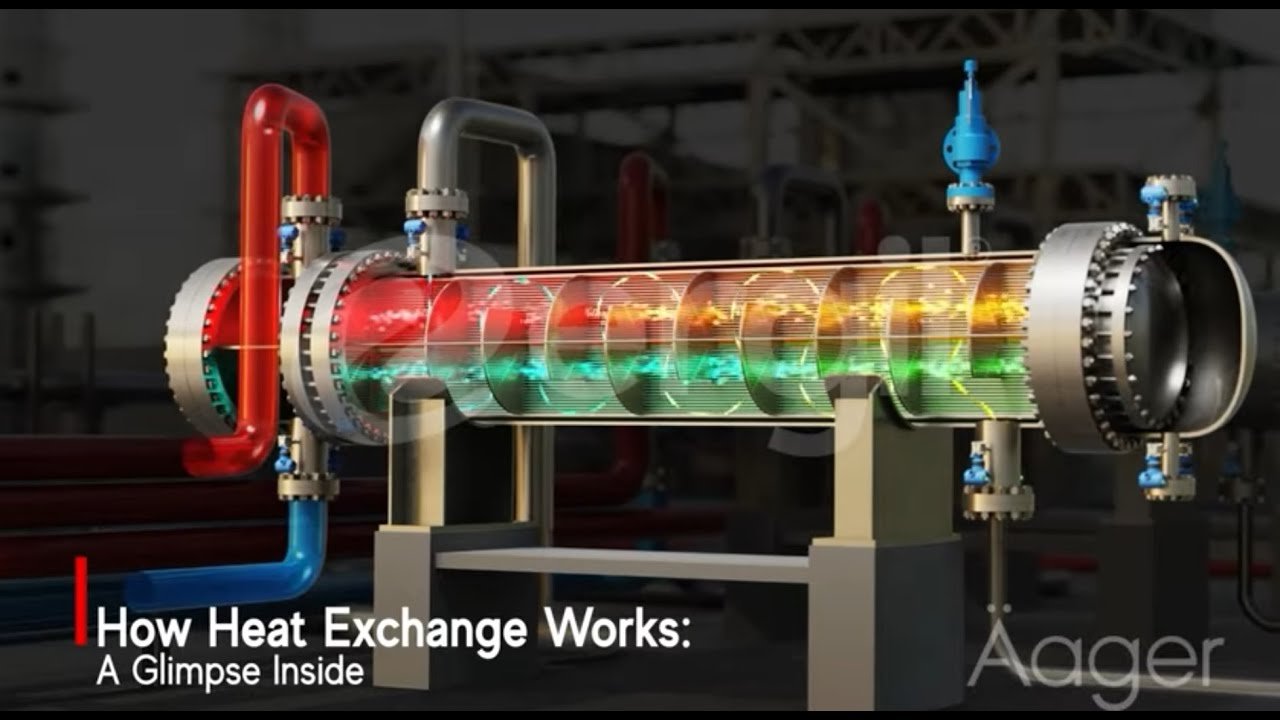

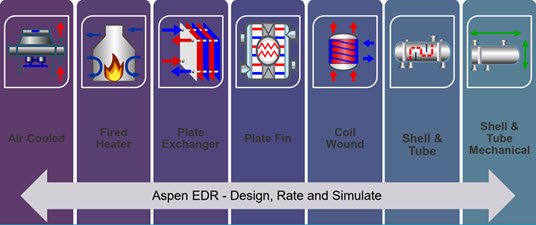

C70600, also known as 90/10 Copper-Nickel, is a marine-grade copper alloy containing 90% copper and 10% nickel. It’s renowned for its outstanding resistance to seawater corrosion, biofouling, and stress corrosion cracking, making it a top choice for condenser tubes and heat exchanger systems, especially in power plants, desalination, and shipbuilding.

This specific product — ASTM B111 C70600 (O61 annealed) seamless tube, with outer diameter 16mm, wall thickness 1.0mm, and length 3000mm — is thoroughly tested with 100% Eddy Current Testing, ensuring every tube is structurally sound and leak-free before use in high-performance systems.

Product Specifications

- Standard: ASTM B111 / ASME SB111

- Grade: C70600 (UNS C70600), 90/10 Copper-Nickel

- Temper: O61 (annealed, for maximum ductility)

- Outer Diameter: 16 mm

- Wall Thickness: 1.0 mm

- Length: 3000 mm

- Type: Seamless Tube

- Testing: 100% Eddy Current Tested (ECT)

- Application: Condensers, coolers, marine heat exchangers

Chemical Composition of C70600 (Typical)

| Element | Content (%) |

|---|---|

| Copper (Cu) | 88.6 min (includes silver) |

| Nickel (Ni) | 9.0–11.0 |

| Iron (Fe) | 1.0–1.8 |

| Manganese (Mn) | ≤ 1.0 |

| Zinc (Zn) | ≤ 1.0 |

| Lead (Pb) | ≤ 0.05 |

| Others (incl. impurities) | ≤ 0.5 |

Nickel and iron in the alloy enhance mechanical strength and seawater corrosion resistance, while maintaining thermal conductivity suitable for condenser performance.

Mechanical Properties (O61 Temper)

| Property | Typical Value |

|---|---|

| Tensile Strength | ≥ 275 MPa |

| Yield Strength | ≥ 105 MPa |

| Elongation (in 5D) | ≥ 30% |

| Hardness (HRB) | ≤ 65 |

| Thermal Conductivity | ~50 W/m·K |

| Maximum Operating Temp | ~300°C (572°F) |

C70600 combines moderate strength with excellent flexibility and long-term reliability under fluctuating thermal and pressure loads.

Key Applications

1. Condenser Tubes (Power Plants & Refineries)

C70600’s excellent resistance to chloride-induced corrosion and biofouling makes it ideal for steam condensers and water-cooled systems.

2. Shipbuilding & Marine Heat Exchangers

Performs reliably in brackish, polluted, or high-velocity seawater, making it suitable for marine engine cooling systems and offshore structures.

3. Desalination Systems

Used in MSF (multi-stage flash) and RO (reverse osmosis) desalination units for long-lasting anti-corrosive performance.

4. Air Conditioning & Refrigeration

Ensures clean heat transfer and resistance to internal corrosion in HVAC systems operating in humid or coastal zones.

100% Eddy Current Testing – Non-Destructive Assurance

Each tube undergoes 100% eddy current testing (ECT) to detect:

- Internal/external flaws

- Surface cracks or pinholes

- Variations in wall thickness

- Manufacturing defects

This test ensures high-integrity tubes, minimizing risk of leaks or failures in critical systems.

Packaging & Delivery

- Packing: End-capped, bundled in PE-wrapped wooden crates for export

- Marking: Clear identification on tubes and bundles (spec, size, heat number)

- Delivery: Global shipping by air or sea with fast turnaround and flexible MOQs

Why Choose ASTM B111 C70600 Copper-Nickel Tubes?

| Advantage | Description |

|---|---|

| Marine-Grade Corrosion Resistance | Withstands seawater, brine, and polluted waters |

| Excellent Heat Transfer | Stable thermal conductivity ensures high system efficiency |

| Low Maintenance | Long service life and low fouling rate |

| Proven Safety | 100% Eddy Current Testing to eliminate defects |

| Weldable & Formable | Easy fabrication during installation and retrofitting |

Call to Action

Upgrade Your Condenser Tubing with Copper-Nickel C70600

For industries where performance, reliability, and corrosion resistance are non-negotiable, DLSS provides ASTM B111 C70600 seamless tubes — tested, certified, and globally trusted.

Request a quote today or speak with a copper alloy specialist:

www.dlsspipeline.com

info@dlsspipe.com

We help engineers and buyers build smarter, longer-lasting systems — with materials designed to perform.