Meta Description:

Explore the differences between bright annealed and pickled stainless steel tubes. Learn which finish is best for your application in terms of corrosion resistance, cleanliness, and industry standards.

Introduction

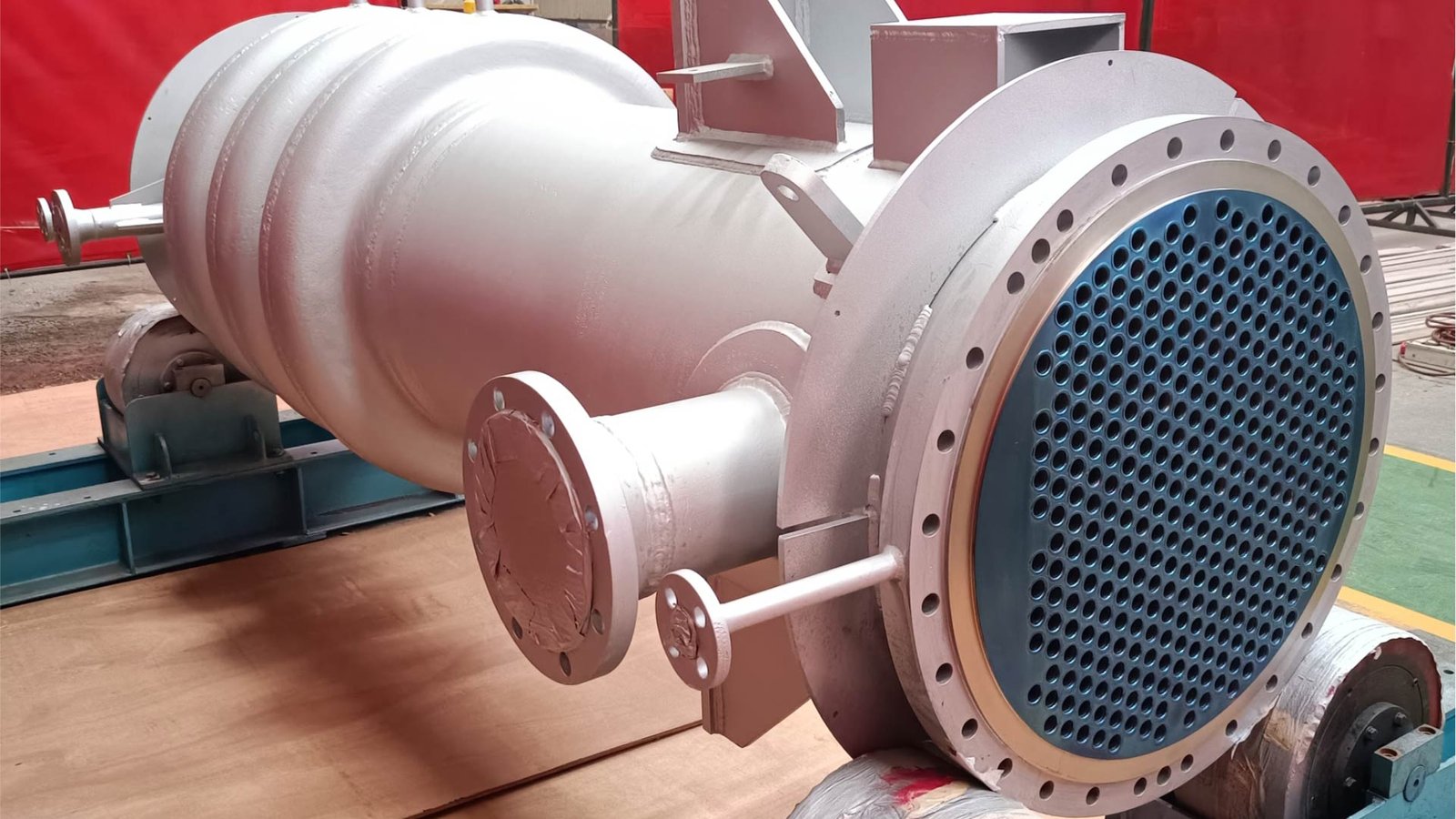

When selecting stainless steel tubes, the surface finish isn’t just cosmetic—it directly affects corrosion resistance, cleanability, and suitability for critical applications such as food processing, pharmaceuticals, or heat exchangers.

The two most commonly specified finishes are:

- Bright Annealed (BA)

- Pickled (Mill Finish or Dull White)

This article will compare these finishes in detail and help you choose the right one based on your industry, environment, and technical requirements.

1. What is Bright Annealed (BA) Finish?

Bright annealed stainless steel tubes are annealed in a controlled, inert atmosphere (typically hydrogen or nitrogen) and then rapidly cooled to produce a mirror-like, reflective finish.

Key Features:

- Smooth, clean surface

- Ra ≤ 0.2 µm (depending on grade and OD)

- Excellent corrosion resistance

- No oxide scale or discoloration

Applications:

- Food & beverage pipelines

- High-purity pharmaceutical systems

- Ultra-clean heat exchanger tubes

- Decorative or architectural components

Reference: Outokumpu Surface Finishes for Stainless Steel Tubes

2. What is Pickled Finish?

Pickled tubes are treated with acid solutions (HNO₃ + HF) to remove mill scale, weld discoloration, and surface oxides. The result is a matte, silver-white finish known for its uniformity and improved corrosion resistance compared to untreated surfaces.

Key Features:

- Dull, clean finish

- Slightly etched surface

- Ra typically ≥ 0.5 µm

- Excellent for general industrial use

Applications:

- Boiler and condenser tubes

- Chemical processing lines

- Marine tubing

- Structural applications

Related Standard: ASTM A380 – Cleaning and Descaling Stainless Steel Parts

3. Comparison Table: Bright Annealed vs Pickled

| Property | Bright Annealed (BA) | Pickled |

|---|---|---|

| Appearance | Shiny, mirror-like | Matte, dull silver |

| Roughness (Ra) | ≤ 0.2 µm | ~0.5–1.0 µm |

| Corrosion Resistance | Excellent (no surface defects) | Good, depends on pickling depth |

| Cleanability | Superior | Moderate |

| Surface Contamination | Minimal | May retain micro-etching marks |

| Cost | Higher | Lower |

| Standard Compliance | ASTM A269 BA | ASTM A269 Pickled, A312 |

4. How to Choose the Right Finish

| Requirement | Recommended Finish |

|---|---|

| Hygienic or ultra-clean systems | Bright Annealed |

| General industrial pipelines | Pickled |

| Decorative or visible surfaces | Bright Annealed |

| Budget-sensitive applications | Pickled |

| High-corrosion environments | Both (depends on grade) |

For electropolished finishes (EP), BA tubes are typically used as a base.

5. DLSS Surface Treatment Capabilities

| Process Type | OD Range | Certification |

|---|---|---|

| Bright Annealing | 6 mm – 76 mm | Ra test, MTC |

| Pickling | 6 mm – 219 mm | A380, photo record |

| Electropolishing | 6 mm – 25.4 mm | Optional |

| Passivation | On request | ASTM A967 |

DLSS also supports custom markings, surface validation (Ra/visual), and photo-documented QC reports with each order.

FAQs

Q1: Can I polish pickled tubes to look like BA tubes?

Not exactly. BA finishes are formed in a controlled atmosphere and are smoother at the microstructural level. Mechanical polishing can improve appearance but not replicate BA’s corrosion resistance.

Q2: Are BA tubes more expensive?

Yes. Bright annealing requires special furnaces and inert atmospheres, making them costlier than pickled tubes.

Q3: Can DLSS supply dual-surface tubes (BA inside, pickled outside)?

Yes. We offer mixed-surface finish options based on application—for example, internal BA for food safety and external pickled for cost savings.

Q4: What finish is best for welding?

Pickled tubes are often better for post-weld passivation and surface blending. However, BA tubes require careful weld zone treatment to maintain internal cleanliness.

Conclusion

Choosing between bright annealed and pickled stainless steel tubes depends on your application’s corrosion risk, hygiene level, and aesthetic needs. At DLSS, we offer both finishes with precision control and full certification, helping you meet project specs and compliance effortlessly.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Not sure which surface finish is ideal for your application? Our technical team is ready to recommend the best-fit option—backed by international standards and factory expertise.