When exporting stainless steel heat exchanger tubes, quality doesn’t stop at production—it must extend through to delivery. Improper packaging can result in corrosion, deformation, contamination, or mechanical damage during transit, especially over long sea voyages.

At DLSS Pipeline, we ensure every shipment arrives in perfect condition with customized export packaging and robust protection tailored to the tube type, transport mode, and client standards.

This article outlines the best practices and DLSS’s standard procedures for packaging and protecting stainless steel heat exchanger tubes.

1. Why Proper Packaging Matters

Stainless steel tubes may appear strong, but they are susceptible to:

- Impact damage during handling or loading

- Pitting corrosion from salt air or condensation

- Ovality or bending if unsupported over long lengths

- Contamination that affects sanitary or cleanroom applications

Correct packaging ensures the tube’s mechanical and surface integrity from our plant to your site—whether by container, breakbulk, or air freight.

2. DLSS Standard Export Packaging Options

We offer flexible packaging tailored to your tube dimensions, finish type, and project requirements:

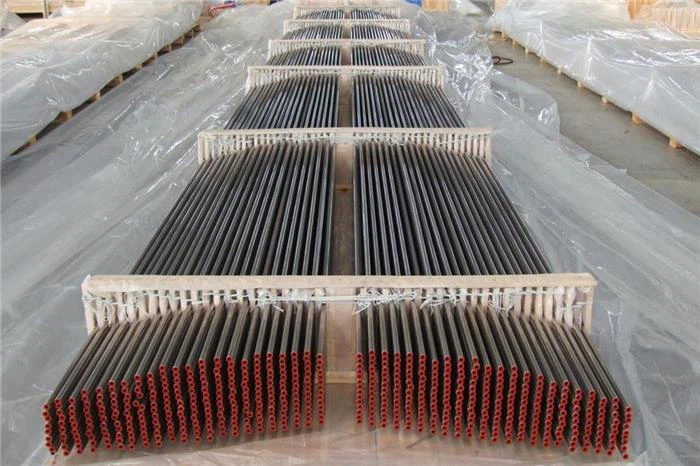

A. Hexagonal Bundles

- Common for seamless tubes

- Tubes aligned and secured with steel straps

- Ends protected with plastic caps

- Bundle wrapped in plastic sheeting or anti-rust film

B. Wooden Boxes / Crates

- Ideal for thin-walled, polished, or U-bent tubes

- ISPM-15 treated solid wood

- Internal supports to prevent shifting

- Desiccant bags and foam padding optional

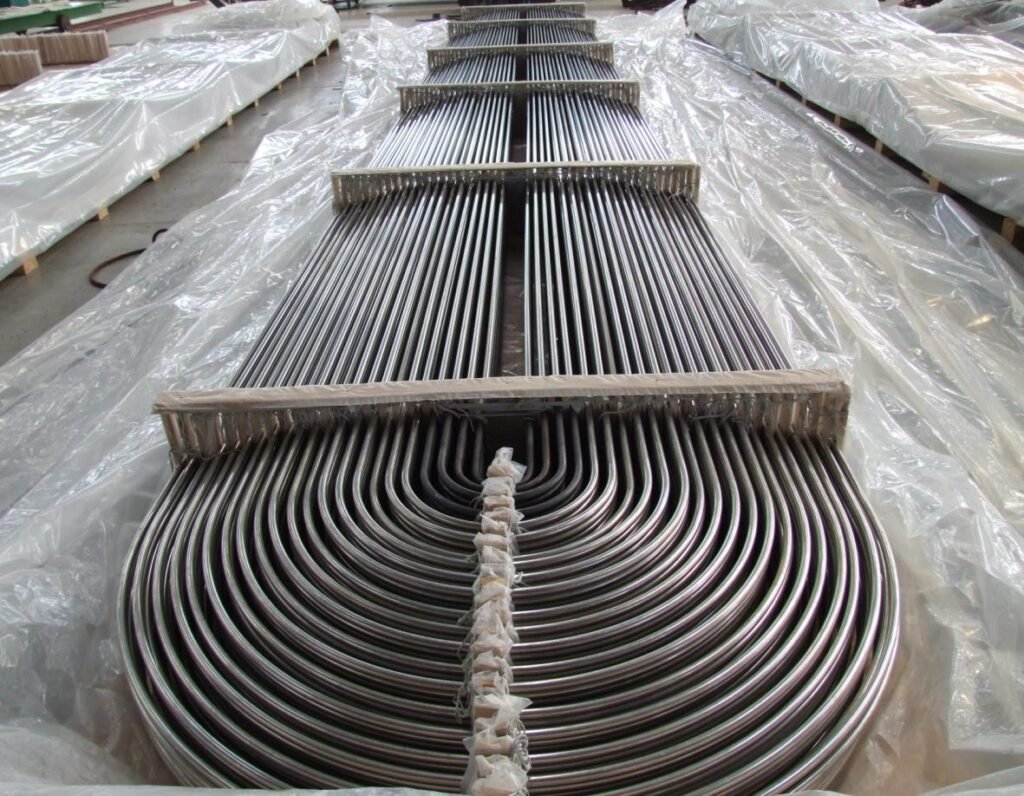

C. U-Bend Tube Packing

- Individual U-tubes match marked and nested

- Ends capped and bundle secured with separators

- Entire bundle packed in wooden box with bend zone support

D. Customized Pallet Packaging

- For short-length tubes or heavy tube sets

- Compatible with forklift and containerized loading

All packages are designed to withstand long-distance transport, high humidity, and container stacking. Learn more at www.dlsspipeline.com

3. Surface and End Protection

To preserve surface quality and prevent contamination:

- Plastic tube caps on both ends

- PE film wrapping for bright annealed or polished tubes

- Oil coating (upon request) for enhanced corrosion resistance

- Paper or foam layers between tubes (for mirror finishes)

These measures are especially important for tubes used in hygienic, sanitary, or instrument-grade applications.

4. Marking, Labeling, and Traceability

DLSS provides complete product traceability with:

- Heat number and size marking on each tube or tag

- Bundle tag with product name, spec, size, quantity, and order number

- Barcode or QR code (optional) for digital tracking

- Stencil or laser marking available per project spec

All shipping documents (packing list, invoice, mill test certificate) are sealed in waterproof sleeves and affixed to the packaging.

5. Seaworthy and Client-Specific Packing

For export shipments, DLSS ensures packaging complies with:

- Seaworthy packing standards (suitable for ocean transit)

- Moisture prevention measures for high-humidity environments

- Client-specific instructions (e.g., NORSOK, Shell, Total, or EPC packaging specs)

- Third-party inspection and packing supervision upon request

Frequently Asked Questions (FAQ)

Q1: Can I request special packing for polished or sanitary-grade tubes?

Yes, we offer foam layering, plastic film wrap, and extra desiccant for sensitive tubes.

Q2: Is DLSS packaging compliant with international phytosanitary rules?

Absolutely. All wooden crates are ISPM 15 heat-treated and marked for customs compliance.

Q3: Do you support bundling by tube length or project section?

Yes, we can group tubes by drawing numbers, client codes, or section use for easier onsite handling.

Conclusion

Proper export packaging is essential to protecting your investment and ensuring smooth, trouble-free project execution. DLSS offers tailored packaging solutions that meet international shipping requirements, minimize risk, and ensure your tubes arrive clean, straight, and ready to install.

To learn more about our packaging options or request a custom export solution, visit DLSS Pipeline.